Compound liquid crystal display device

A liquid crystal display device and composite technology, which is applied in the fields of instruments, computing, electrical and digital data processing, etc., can solve the problems of increasing cell thickness, insensitivity, and disturbing touch, and achieve the effect of increasing sensitivity and reducing cell thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

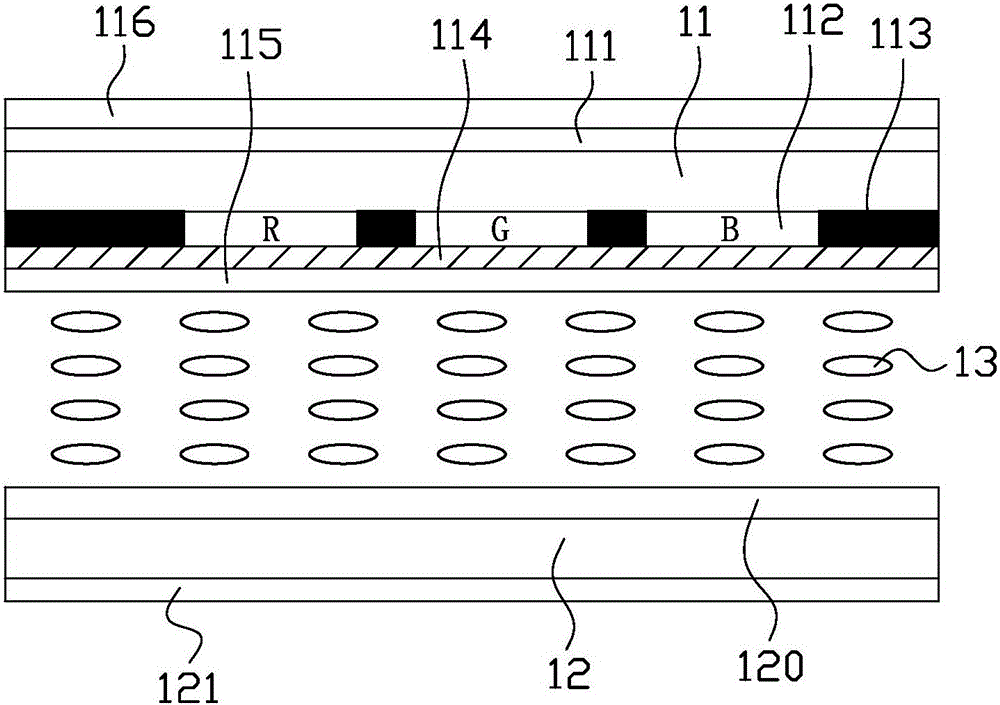

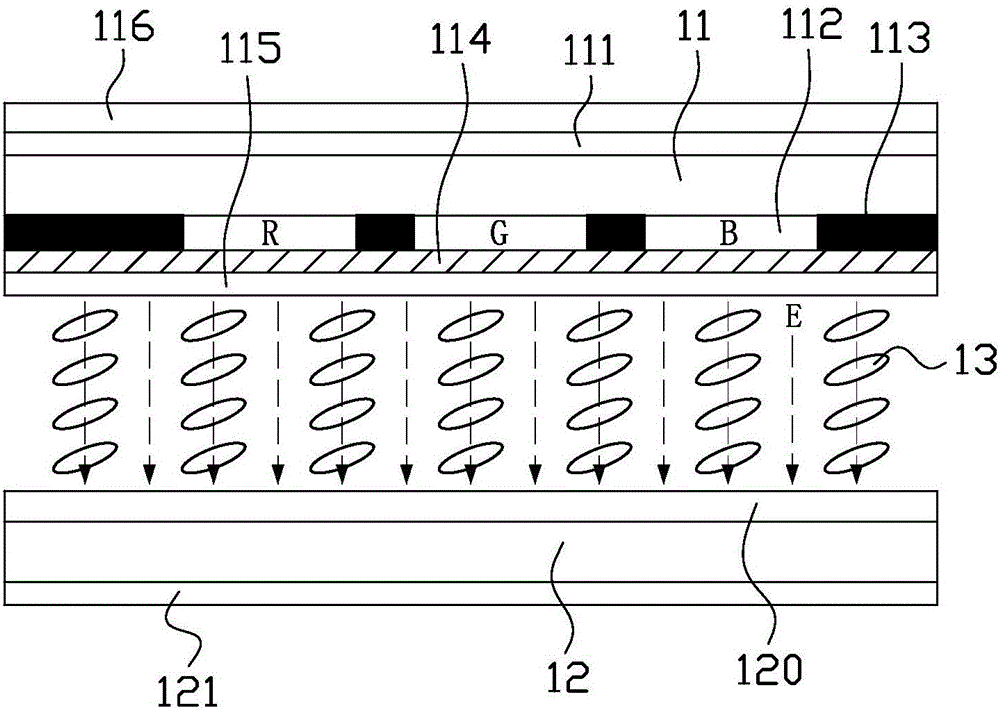

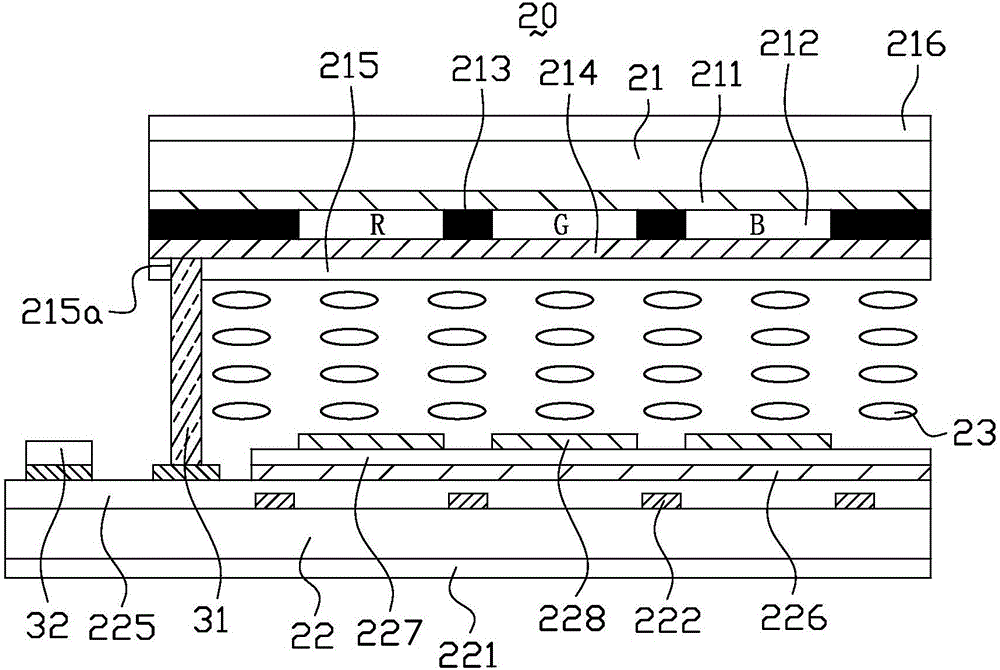

[0032] image 3 It is a schematic cross-sectional view of a liquid crystal display device at a wide viewing angle in the first embodiment of the present invention, Figure 4 for image 3 Schematic diagram of the cross-section of a liquid crystal display device at a narrow viewing angle, please refer to Figure 3 to Figure 4 The liquid crystal display device 20 provided in this embodiment includes a first substrate 21 , a second substrate 22 opposite to the first substrate 21 , and a liquid crystal layer 23 between the first substrate 21 and the second substrate 22 . Wherein, the first substrate 21 is a color filter substrate, and the second substrate 22 is a thin film transistor array substrate.

[0033] The liquid crystal display device 20 is an in-plane switching (IPS) liquid crystal display device using a horizontal electric field or a fringe field switching (FFS) liquid crystal display device using a fringe electric field. For IPS-type or FFS-type liquid crystal display...

no. 2 example

[0052] Figure 6 It is a schematic cross-sectional view of the liquid crystal display device in the second embodiment of the present invention, please refer to Figure 6 The main difference between this embodiment and the above-mentioned first embodiment is that, in this embodiment, a touch circuit layer 216, an insulating spacer layer 217, a second A polarizer 211 , a color resist layer 212 , a black matrix (BM) 213 , a viewing angle control electrode 214 and a flat layer 215 .

[0053] The touch circuit layer 216 is disposed on the inner surface of the first substrate 21 . The insulating spacer layer 217 is disposed on the touch circuit layer 216 . The first polarizer 211 is disposed on the insulating spacer layer 217 , that is, the touch circuit layer 216 is separated from the first polarizer 211 by the insulating spacer 217 . The first polarizer 211 is made of a metal material, and the first polarizer 211 can be formed specifically by using a metal wire grid process or ...

no. 3 example

[0057] Figure 7 It is a schematic cross-sectional view of the liquid crystal display device in the third embodiment of the present invention, please refer to Figure 7The main difference between this embodiment and the above-mentioned second embodiment is that in this embodiment, the order of the insulating spacer layer 217, the color resist layer 212 and the black matrix 213 is interchanged, that is, the touch circuit layer 216 is arranged on the first On the inner surface of the substrate 21 , for example, the touch circuit layer 216 is directly formed on the inner surface of the first substrate 21 . The color resist layer 212 and the black matrix 213 are staggered and disposed on the touch circuit layer 216 . The first polarizer 211 is disposed on the color resist layer 212 and the black matrix 213 , that is, the touch circuit layer 216 and the first polarizer 211 are separated by the color resist layer 212 and the black matrix 213 . The insulating spacer layer 217 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com