Electric equipment and its motion control method

An electric and equipment technology, applied in the direction of electric speed/acceleration control, etc., can solve the problems of inability to respond to the position information of the transmission module in real time, the influence of system stability and service life, and the addition of position sensors or grating encoders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

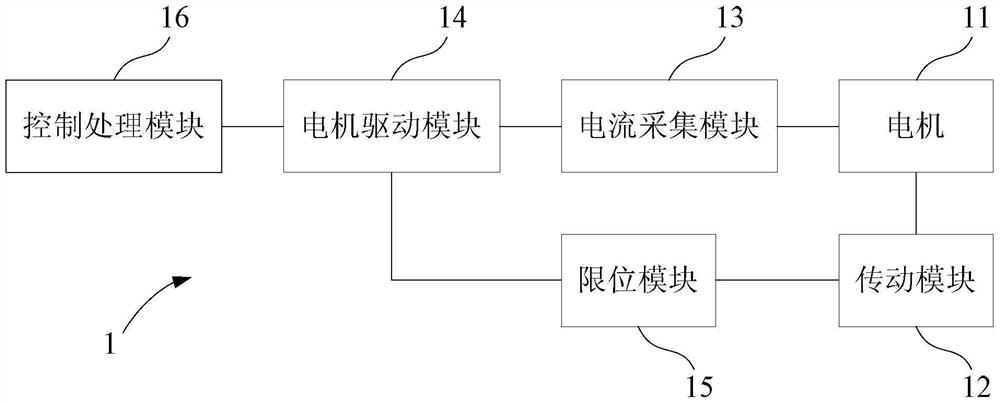

[0012] like figure 1 As shown, the electric device 1 provided in this embodiment includes: a motor 11 , a transmission module 12 , a current collection module 13 , a motor drive module 14 , a limit module 15 and a control processing module 16 . Each module is described in detail below, and the corresponding motion control method of the electric device is explained through the description.

[0013] The motor 11 is a power conversion device of the electric device 1 , and the parameters of different motors are different, so in practical applications, the parameters of the motor are determined by the specific motor model. In this embodiment, the motor 11 may be a DC motor.

[0014] The transmission module 12 is a mechanical transmission mechanism controlled by the motor 11, which realizes the conversion from the rotation of the motor to the linear motion. Taking the electric device as a medical pendant as an example, the transmission module 12 is the mechanical application trans...

Embodiment 2

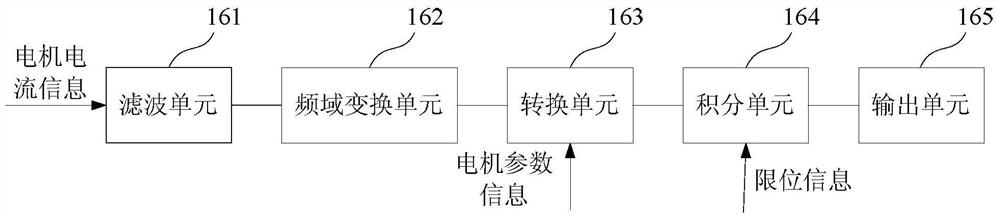

[0024] This embodiment is an improvement made on the basis of Embodiment 1, specifically: considering that there is an accumulated error in the integration, after a period of use, the position deviation will become larger and larger, so the control processing module 16 of this embodiment also It is used to adjust the integral constant in the integral unit 164 to the value corresponding to the limit position when the limit module 15 is triggered. In this way, the limit module 15 will be used as the position reference of the transmission module 12. When the limit module 15 is triggered, the integral unit 164 of the control processing module 16 will correct the constant of the integral part, thereby clearing the cumulative error of the integral and ensuring the long-term operation of the system. accuracy. It can be seen that the online real-time calibration of the electric device 1 can be realized in combination with the limit module 15 , without additional calibration and calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com