Built-in common-mode electric reactor of three-phase electric reactor

A technology of three-phase reactors and reactors, which is applied in the direction of inductors, fixed inductors, transformer/inductor cores, etc., can solve the problem of inability to filter out zero-sequence common-mode harmonics, difficulty in satisfying inductance, and large common-mode Harmonic and other problems, to achieve the effect of reducing body size, improving performance and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

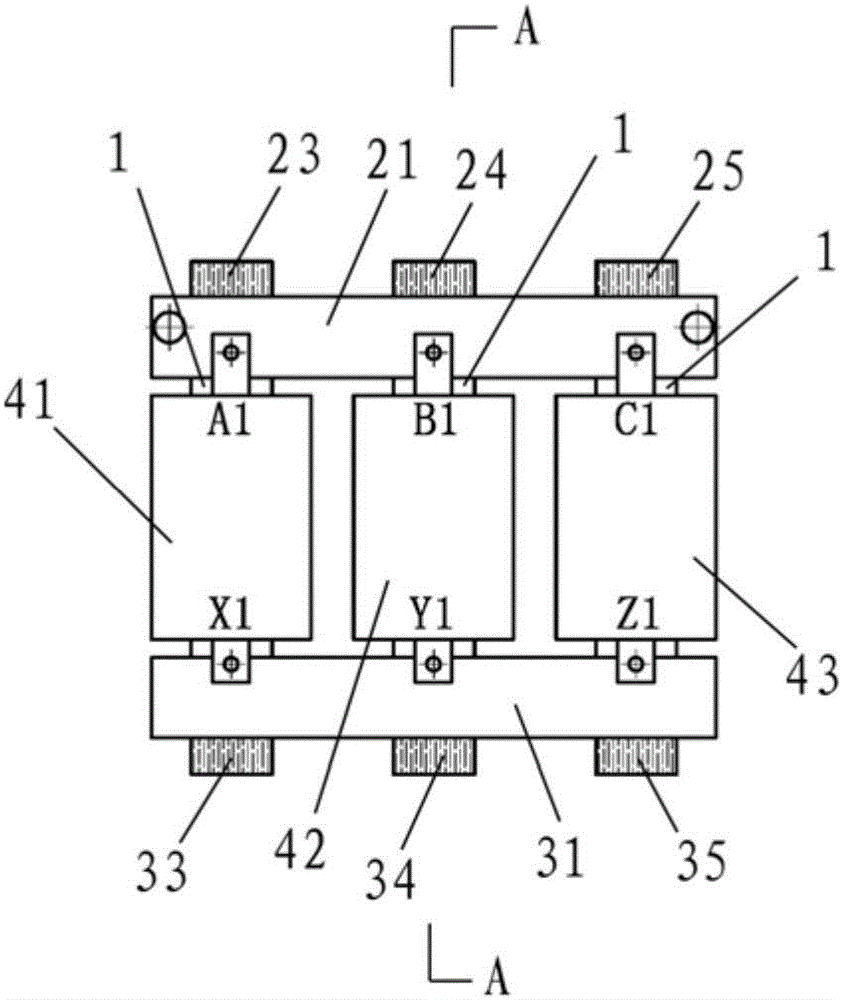

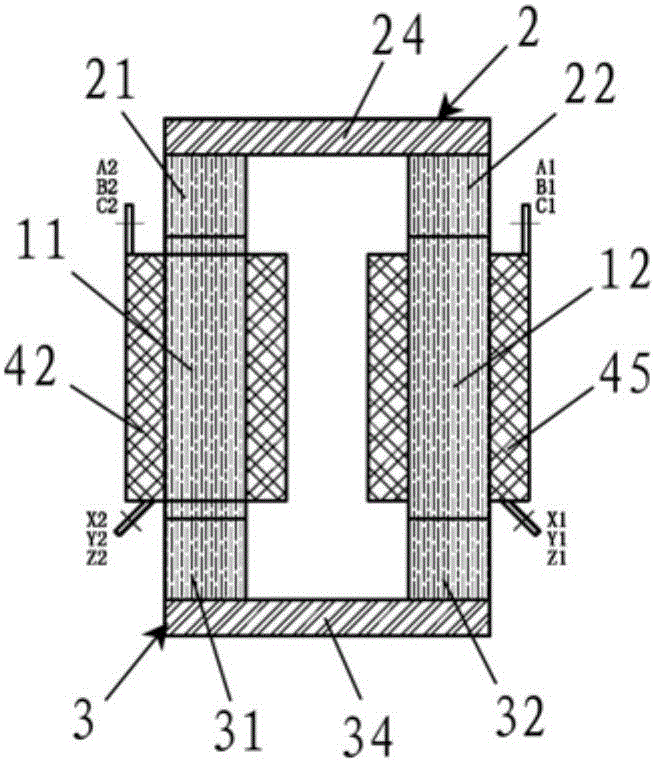

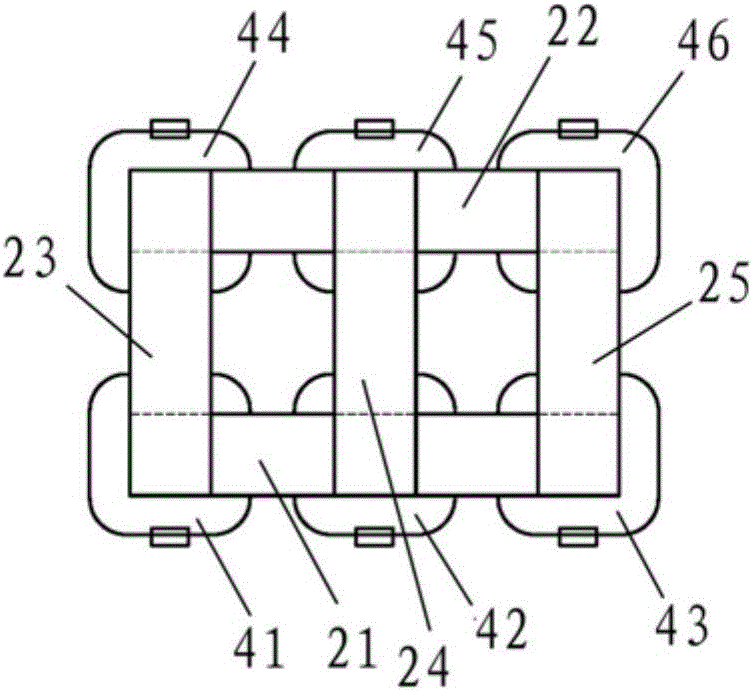

[0035] Such as Figure 1-4 The three-phase reactor shown has a built-in common mode reactor, including six iron core columns 1 , five upper iron yokes 2 and five lower iron yokes 3 .

[0036] For the convenience of description, the six iron core columns are respectively referred to as the first iron core column, the second iron core column, the third iron core column, the fourth iron core column, the fifth iron core column, and the sixth iron core column; The upper iron yokes are respectively called the first upper iron yoke 21, the second upper iron yoke 22, the third upper iron yoke 23, the fourth upper iron yoke 24, and the fifth upper iron yoke 25; the five lower iron yokes are respectively called The first lower iron yoke 31 , the second lower iron yoke 32 , the third lower iron yoke 33 , the fourth lower iron yoke 34 , and the fifth lower iron yoke 35 .

[0037] Each iron core column 1 is wound with a coil 4 , corresponding to each iron core column, respectively coil 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com