A multi-pass control method based on long-distance material conveying device

The technology of a conveying device and control method is applied in the field of multi-transmission control based on long-distance material conveying devices, which can solve problems such as tearing conveyor belts, uneven load distribution, and interference with surrounding equipment, achieve balanced output, reduce downtime rates, Avoiding the effect of local drive point overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

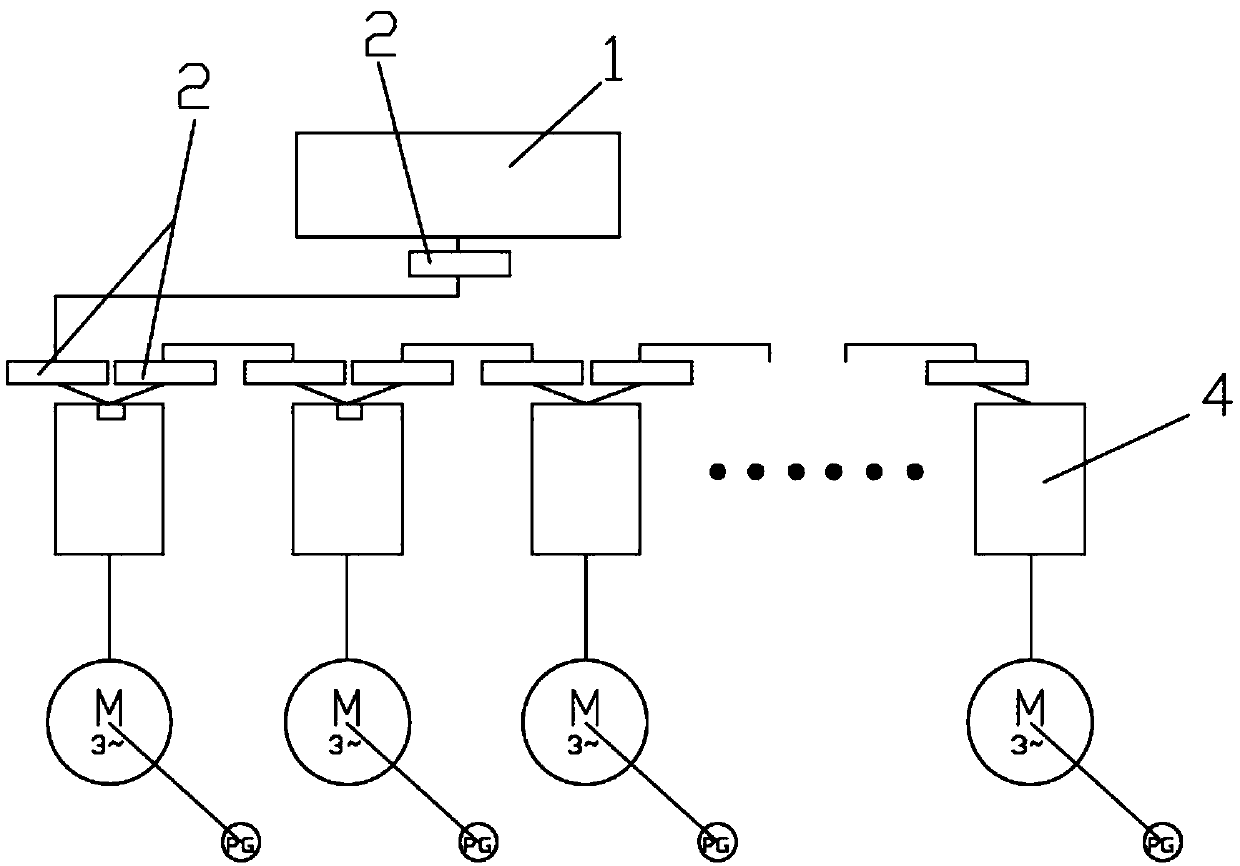

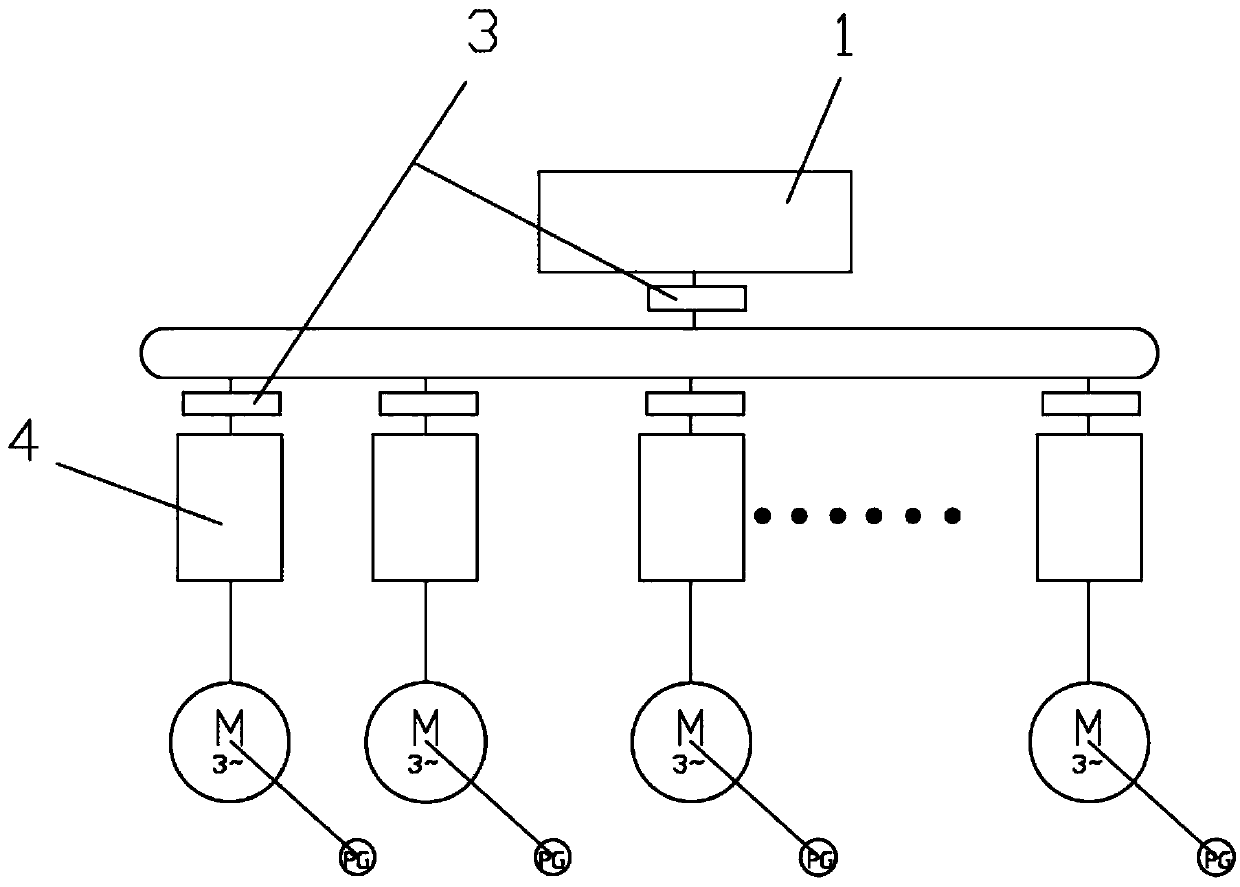

[0056] The present invention provides a multi-pass control method based on a long-distance material conveying device, the steps of which are as follows:

[0057] S1: Synchronous control system access: Install frequency converter 4 in each transmission device of the long-distance material conveying device, so that the motor speed measurement feedback encoder in each transmission device is connected to frequency converter 4, and frequency converter 4 is controlled by the load distribution algorithm Device 1 is electrically connected;

[0058] S2: Data collection: collect the current values of voltage, current, speed and torque of each frequency converter, and transmit the collected data to the load distribution algorithm controller 1;

[0059] S3: Calculation of the speed and torque of each frequency converter: transmit the data collected in step S2 to the load distribution algorithm controller 1 through optical fiber communication, call the load distribution control algorithm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com