Manufacturing process of mould cups for invisible brassiere and invisible brassiere

A preparation process and mold cup technology, applied in bras, applications, clothing and other directions, can solve the problems of short service life of invisible bras, easy to lose shape of invisible bras, not strong enough viscosity, etc., so as to improve the gathering effect and the adhesion force. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

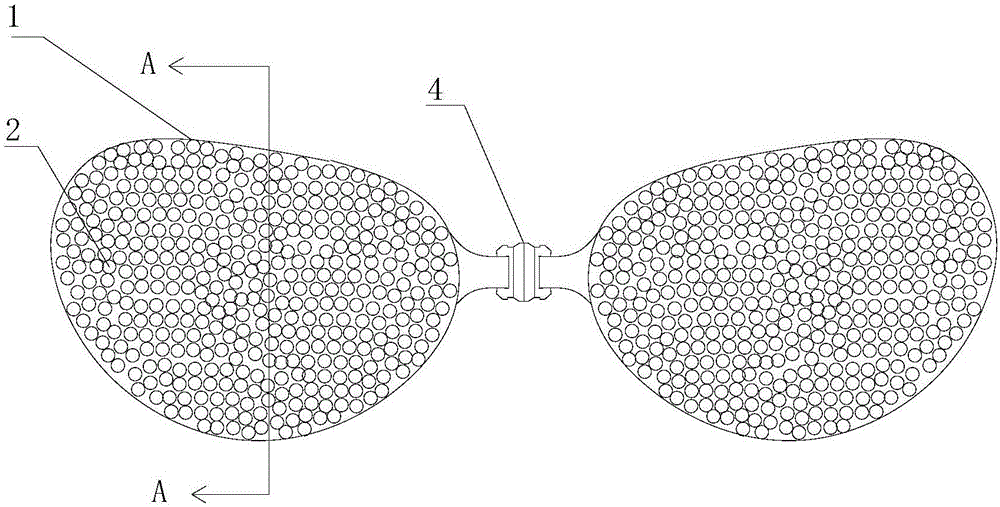

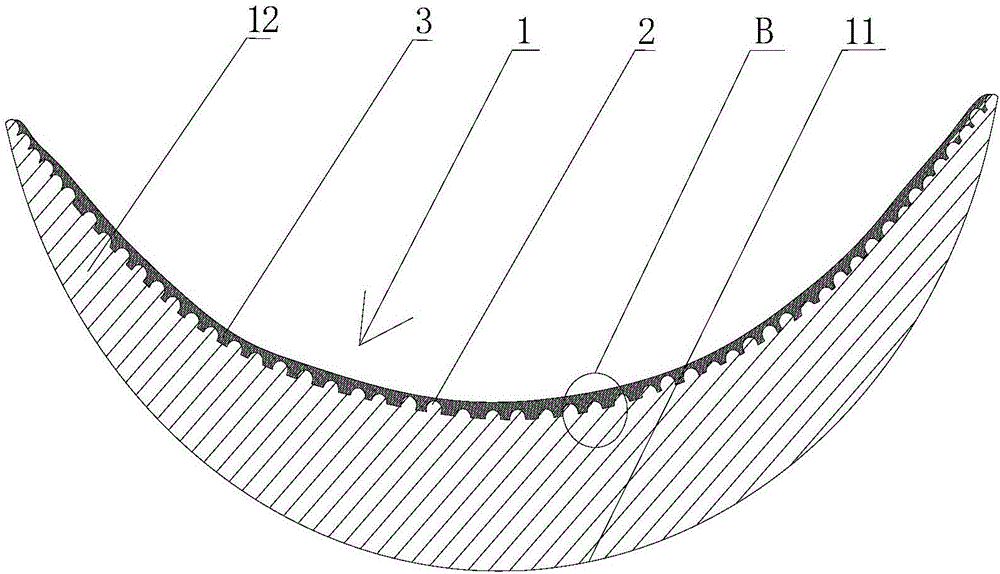

[0032] Preparation of mold cups for invisible bras:

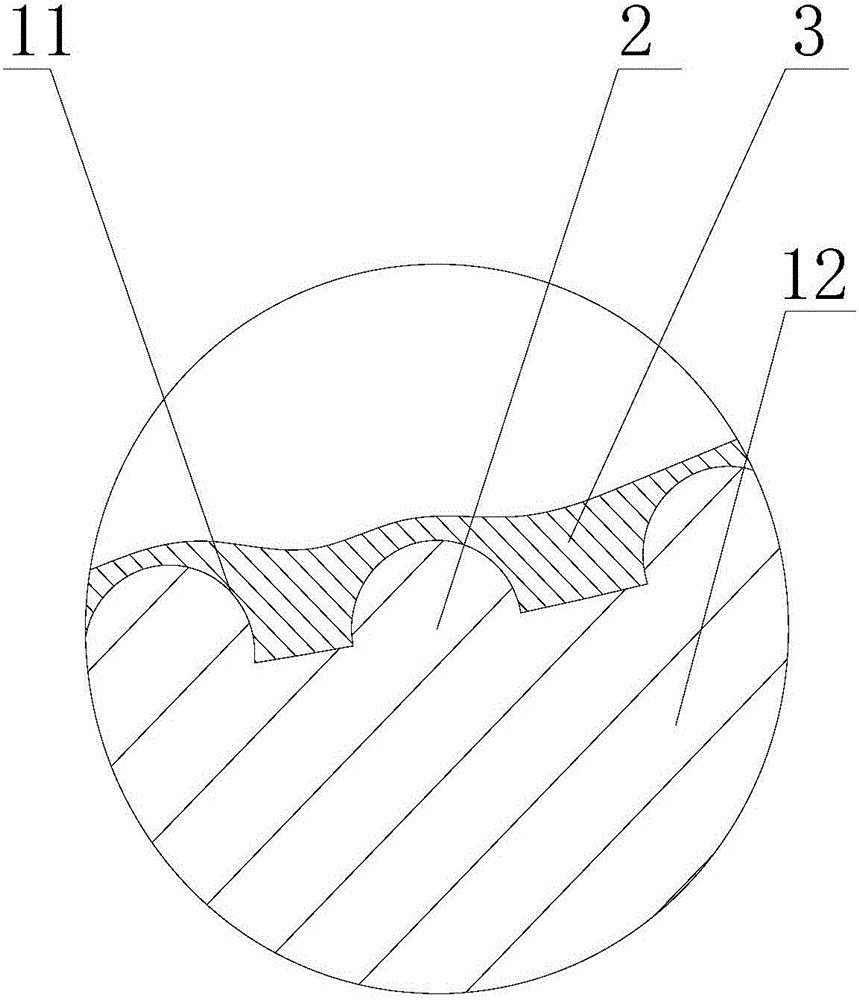

[0033] Step 1: Prepare a TPU film bag, pour silica gel into the TPU film bag, then seal the bag and heat it to shape and make the concave part of the obtained mold cup semi-finished product form several bumps, press out the buckle, and the processing temperature during shaping is 150 ±5°C, where the thickness of the side of the TUP film bag close to the inner side of the mold cup is 4 wires. It should be noted that before sealing the TPU film bag, the air bubbles in the TPU film bag should be removed first, and then the bag should be sealed.

[0034] Step 2: Apply glue evenly on the concave part of the mold cup semi-finished product to prepare a glue layer, and bake it at 120±5°C to shape the glue layer. The shaped glue layer forms a smooth curved surface in the concave part of the mold cup.

[0035] The invisible bra can be obtained by connecting two mold cups prepared by the above-mentioned preparation process through a ...

Embodiment 2

[0042] The preparation method is the same as that of Example 1, except that in the shaping process, a mold with an extended end is used to press to obtain a mold cup 1 with an extension 5, specifically, the mold cup 1 One end is a pointed portion 51 , the other end of the mold cup is a heart portion 52 , and an extension portion 5 is provided outside the pointed portion 51 .

[0043] Its structure is as Figure 5 shown.

[0044] The advantage of this embodiment is that the extension part 5 improves the collection capacity of the auxiliary milk and improves the gathering effect, and the buckle 4 further improves the gathering effect.

Embodiment 3

[0046] The preparation method is the same as that of Example 1, except that in step 1, 10 wt% of far-infrared powder is added to the silica gel in the TPU film bag.

[0047] It makes the invisible bra of this embodiment have a good health care effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com