Adjustable compression-type atomizer

A nebulizer and compression technology, which is applied in therapeutic nebulizers, medical devices, and other medical devices, can solve the problems of different disease adjustments, inconvenient operation, single function, etc., and achieve a clever overall design , Easy to promote and apply, practical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

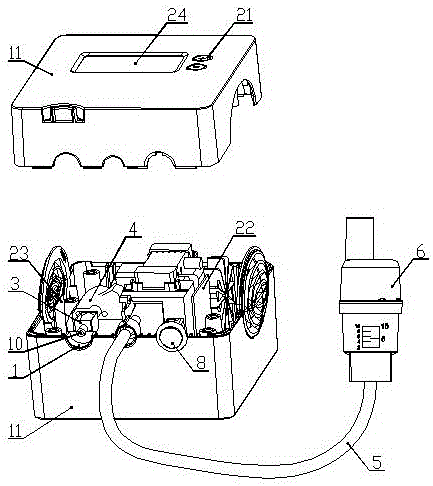

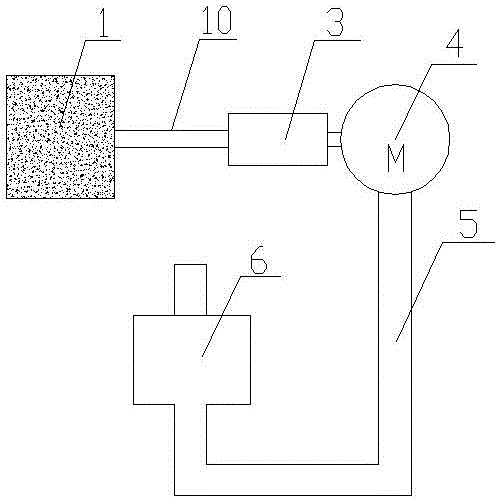

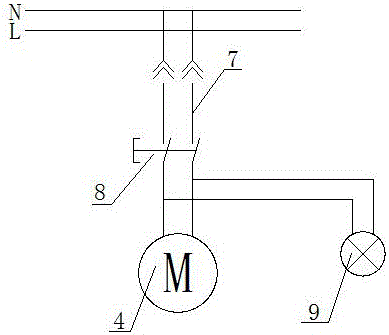

[0016] Example 1: see figure 1 , figure 2 , image 3 , an adjustable compression atomizer, the atomizer includes a casing 11, a compressor 4, an air intake pipe 10, an air intake filter element 1, an air intake valve 3, an air outlet pipe 5, an atomizing cup 6, and a power cord 7 , switch 8, indicator light 9 and control circuit, the atomizing cup 6 communicates with the air outlet port of the compressor 4 through the air outlet pipe 10, and the casing 11 is provided with a cooling hole, a power switch, an indicator light and an atomizing cup holder, The air supply pipe can send the compressed air output by the compressor into the atomizing cup for atomization. The air intake filter element is connected to the air intake port of the compressor through the air intake pipe after being connected in series with the air intake valve. The parallel circuits of the compressor and the indicator light are connected in series, and the casing 11 is used for the structural connection be...

Embodiment 2

[0017] Example 2: see figure 1 , figure 2 , image 3 As an improvement of the present invention, the control circuit includes a button 21, a single-chip microcomputer 22 and an intake valve drive module 23. The intake valve control circuit inputs a control signal to the single-chip microcomputer 22 from the button 21, and then the single-chip microcomputer 22 supplies the intake valve. The drive module 23 inputs the command signal, and the intake valve drive module 23 converts the command signal into a voltage signal that drives the coil of the intake valve 3 to control the air flow of the intake valve. The microcontroller 22 is also connected to the display 24 to display the parameters of the atomizer. information. Input a signal to the single-chip microcomputer through the button, the single-chip microcomputer calculates and stores the signal, and then sends the signal to the intake valve driving module, which converts the signal of the single-chip microcomputer into a se...

Embodiment 3

[0018] Example 3: see figure 1 , figure 2 , image 3 , as an improvement of the present invention, the intake valve is mainly composed of a valve core and a control coil, and the display and buttons are arranged above the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com