A pipeline inner wall spraying robot

A spraying robot and spraying mechanism technology, applied in the direction of spraying device, etc., can solve the problems of difficult secondary reinforcement, cumbersome operation, complex structure, etc., and achieve the effect of improving operation efficiency, reducing labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

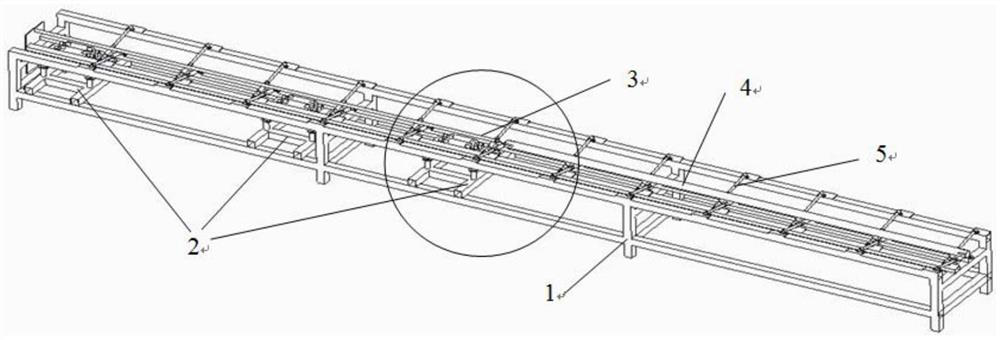

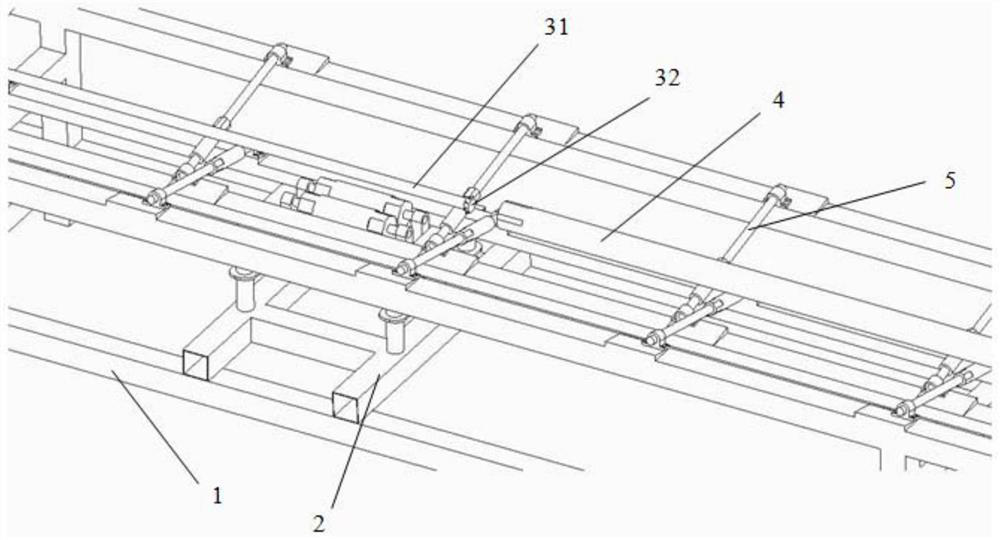

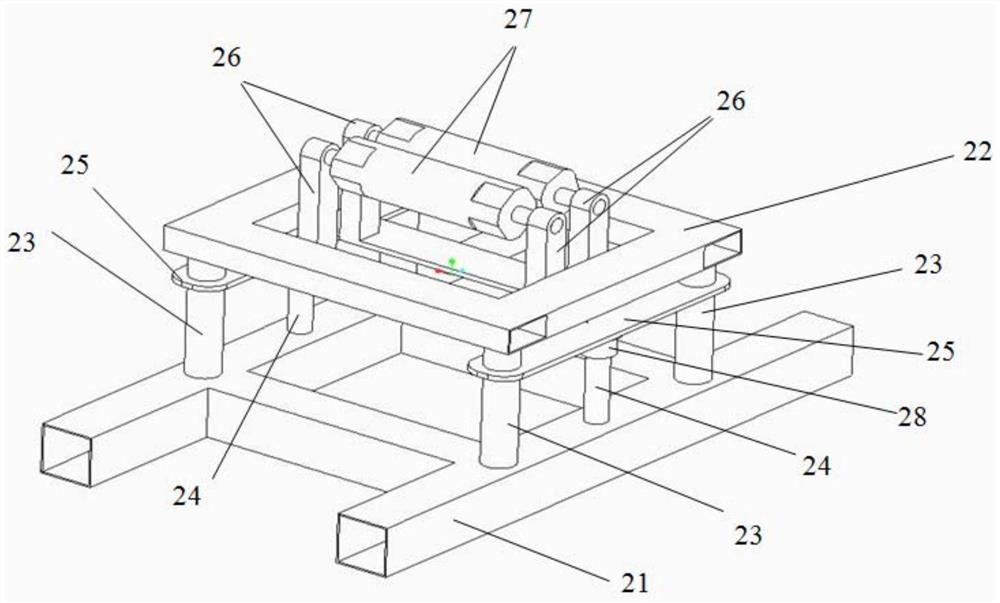

[0030] according to the above figure 2 , image 3 ,and Figure 4 As shown, a robot for spraying the inner wall of a pipeline is produced, in which there are 3 lifting and rotating mechanisms, 48 wedge-shaped pads in total, the wedge angle of the wedge-shaped pads is 30°, 48 supports, and 24 electric rollers B. The setting method of the electric roller B is sequentially cross-symmetrical. The operation control program of the PLC is: start the equipment → start → detect whether the pipeline to be sprayed is placed in the station, if no, alarm; if yes, start the high-speed conveying pipeline → detect whether the nozzle enters Pipeline, no, continue high-speed conveying, low-speed conveying → turn on the nozzle to start spraying operation → check whether the spraying operation is completed → no, continue spraying operation; yes, lift the rotating mechanism to rise → detect whether the lifting and rotating mechanism is in contact with the outer wall of the pipeline → no, contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com