A four-high reversing rolling mill equipped with an automatic strip centering device and its deviation correction method

An automatic centering and strip technology, applied in guiding/positioning/aligning devices, length measuring devices, rolling mill control devices, etc., can solve problems such as reducing the operator's operating intensity, distinguishing with the naked eye or measuring with a tape measure. , to avoid serious deviation, improve accuracy and reference, and reduce rolling accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the technical solution of the present invention, the inventor of the present invention will describe in detail below in conjunction with the accompanying drawings through specific embodiments:

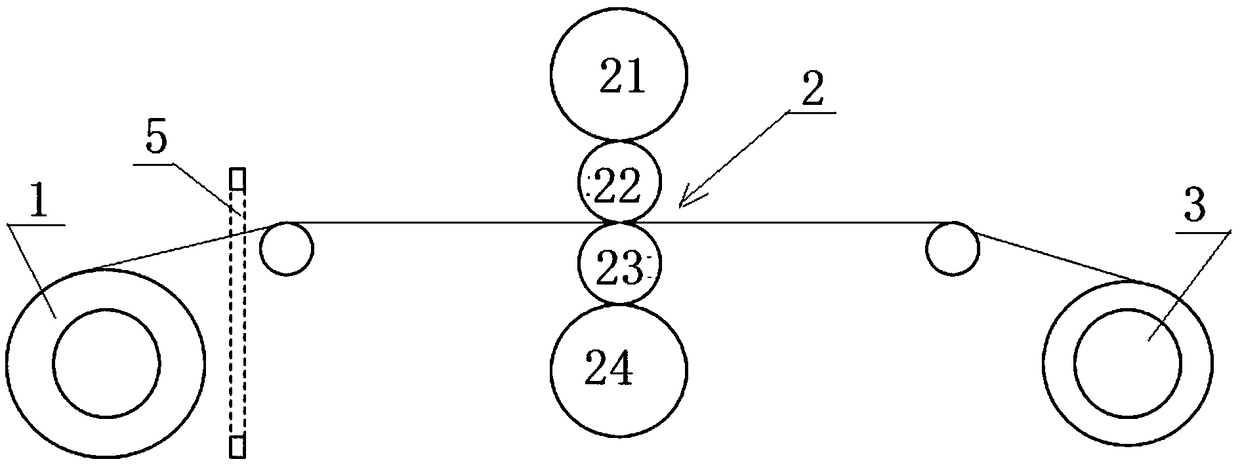

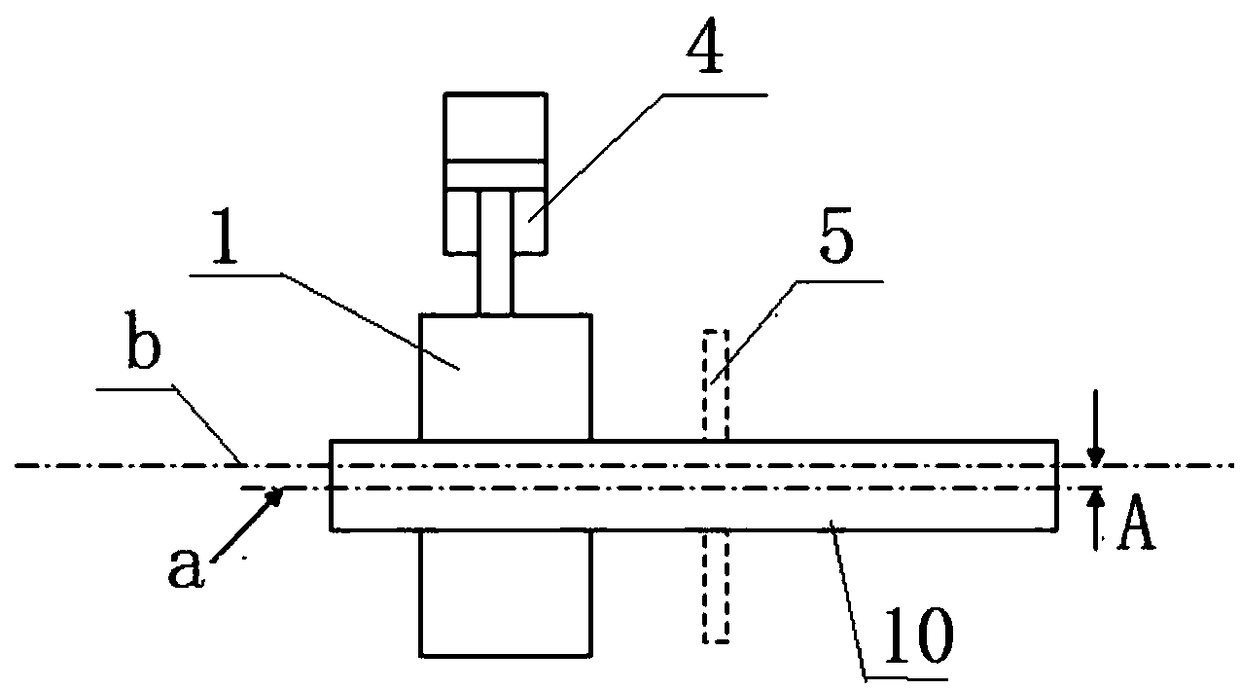

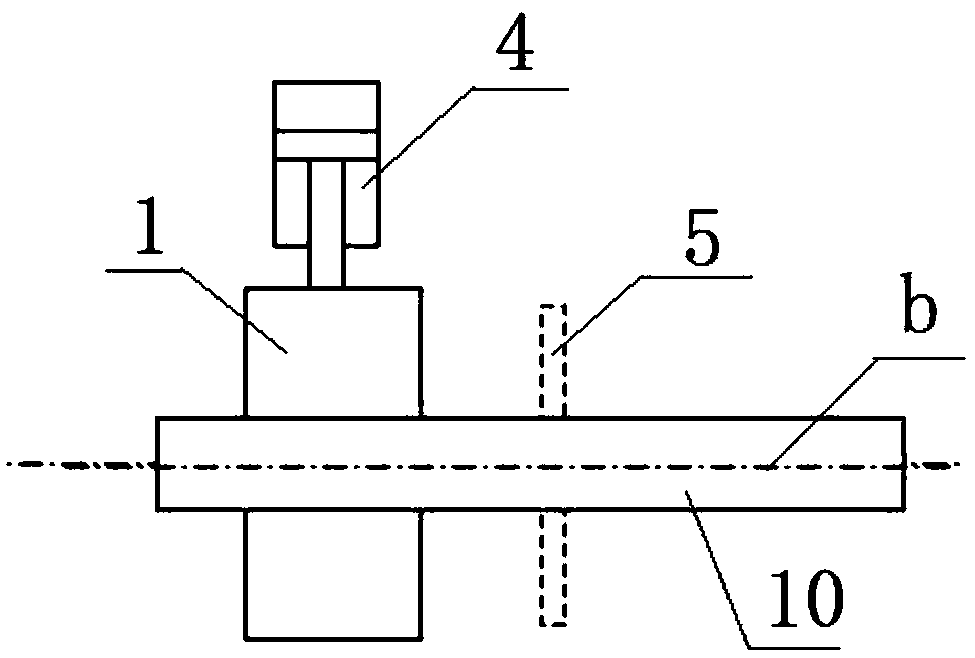

[0035] see figure 1 with Figure 2a, a four-high reversible rolling mill equipped with an automatic strip centering device 5, including a left coiler 1, a rolling mill body 2, a right coiler 3 and an electric control system, a left coiler 1, a rolling mill body 2 and a right The coiler 3 is arranged in sequence from left to right; the rolling mill main body 2 includes an upper back-up roll 21, an upper work roll 22, a lower work roll 23 and a lower back-up roll 24 arranged in sequence from top to bottom, and the front side of the rolling mill main body 2 is for operation side, the rear side of the rolling mill main body 2 is the transmission side; the electric control system includes a controller and a man-machine interface connected to it, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com