A production process of high-strength 2024 aluminum alloy thin-walled corner profiles

A production process and technology for aluminum alloys, applied in the field of aluminum alloys, can solve problems such as low yield and production efficiency, and achieve the effects of improving yield, reducing extrusion resistance, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

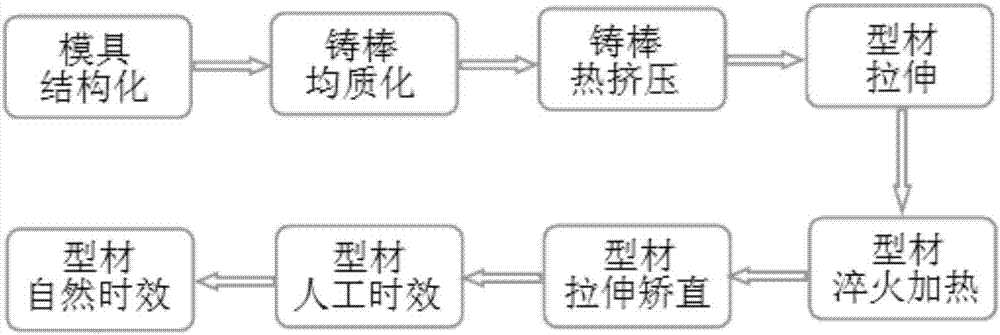

[0032] Such as figure 1 As shown in the production process flow, a kind of high-strength 2024 aluminum alloy thin-wall angle profile production process provided by the present invention, concrete following steps:

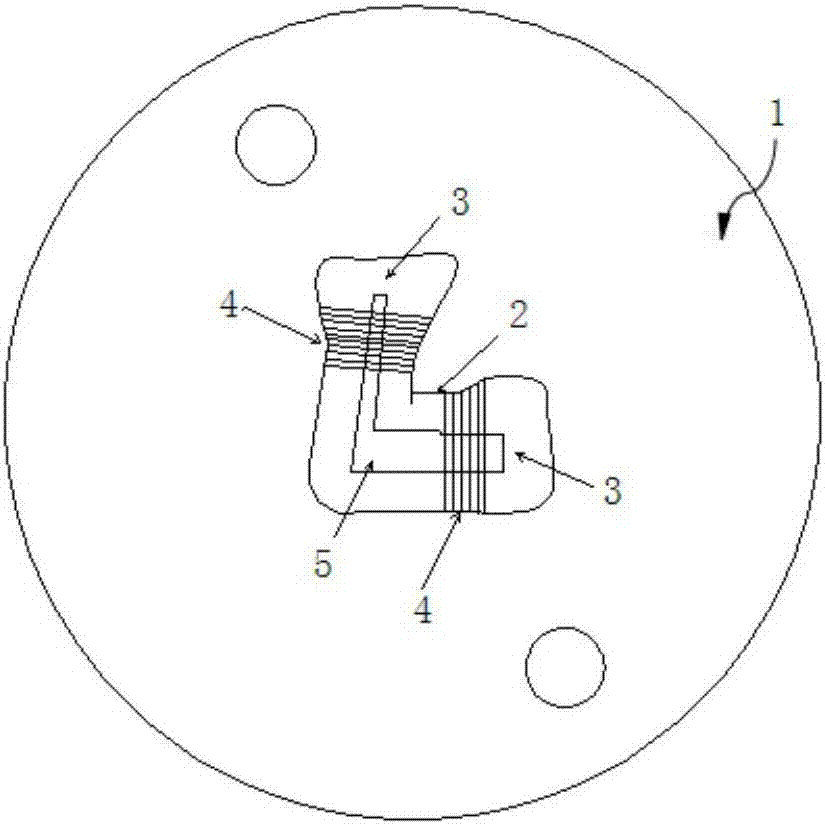

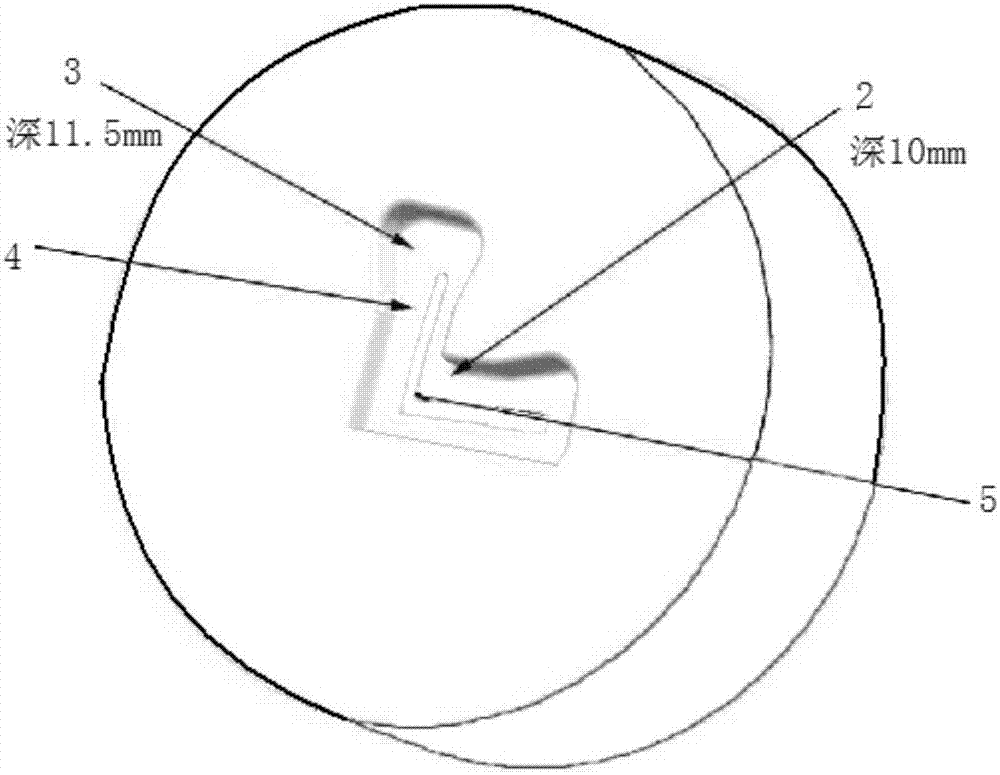

[0033] (1) Structuring the mold, that is, adding a diversion structure in the extrusion groove of the mold;

[0034] (2) Carry out homogenization treatment on the cast rod, that is, the homogenization temperature is 485°C, and the time is 22h;

[0035] (3) Perform hot extrusion treatment on the cast rod, that is, preheat the cast rod, mold and extrusion cylinder to 410°C, 450°C and 445°C respectively before extrusion of the homogenized cast rod, and Extrusion speed can be increased to 0.8m / min for middle profile extrusion;

[0036] (4) The profile is stretched, that is, the hot-extruded profile is clamped into a stretching device and stretched, and the stretching elongation is 1%;

[0037] (5) Carry out quenching and heating treatment on the profile, that is, sen...

Embodiment 2

[0044] The difference between this example and Example 1 is that: in step 2), the homogenization treatment temperature is 495°C, and the time is 28h; in step 3), the cast rod, mold and extrusion cylinder are respectively Preheat to 415°C, 455°C and 450°C, and the extrusion exit speed of the profile can be increased to 0.9m / min during extrusion; in step 4), the tensile elongation is 1.2%; in step 5) In step 6), the quenching temperature is 465°C; in step 6), the tensile elongation is 0.4%; and then immediately shaped, and after the straightening is completed, the clamping parts at both ends of the profile are cut off, and the middle part is reserved. By adopting the above scheme, the present invention can increase the extrusion efficiency of the angle profile to 0.9m / min, and the degree of grain refinement is relatively high.

Embodiment 3

[0046]The difference between this embodiment and the above-mentioned embodiment is that: in step 2), the homogenization treatment temperature is 490°C, and the time is 25h; Preheat to 420°C, 460°C and 460°C, and the extrusion exit speed of the profile can be increased to 1.0m / min during extrusion; in step 4), the tensile elongation is 1.5%; in step 5) In step 6), the quenching temperature is 470°C; in step 6), the tensile elongation is 0.5%; and then immediately shaped, and after the straightening is completed, cut off the clamping parts at both ends of the profile, and retain the middle part; in step 7 ) before, artificial aging treatment is also carried out on the profiles, that is, the stretched and straightened profiles are put into an aging furnace with a circulating hot air device and two-stage artificial aging is carried out. 15~20h, the temperature of the second stage is 145~170℃, and the time is 6~10h. When loading the furnace, ensure that there is a gap of more than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com