Assembly method of flexible combined fixture for laser cutting tooling

A combined fixture and laser cutting technology, which is applied in the direction of manufacturing tools, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of insufficient clamping accuracy and high manufacturing cost, and achieve saving fixture design, reducing production costs, and flexible structure changeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] The invention provides a method for assembling a flexible combined fixture for laser cutting tooling, which specifically includes the following steps:

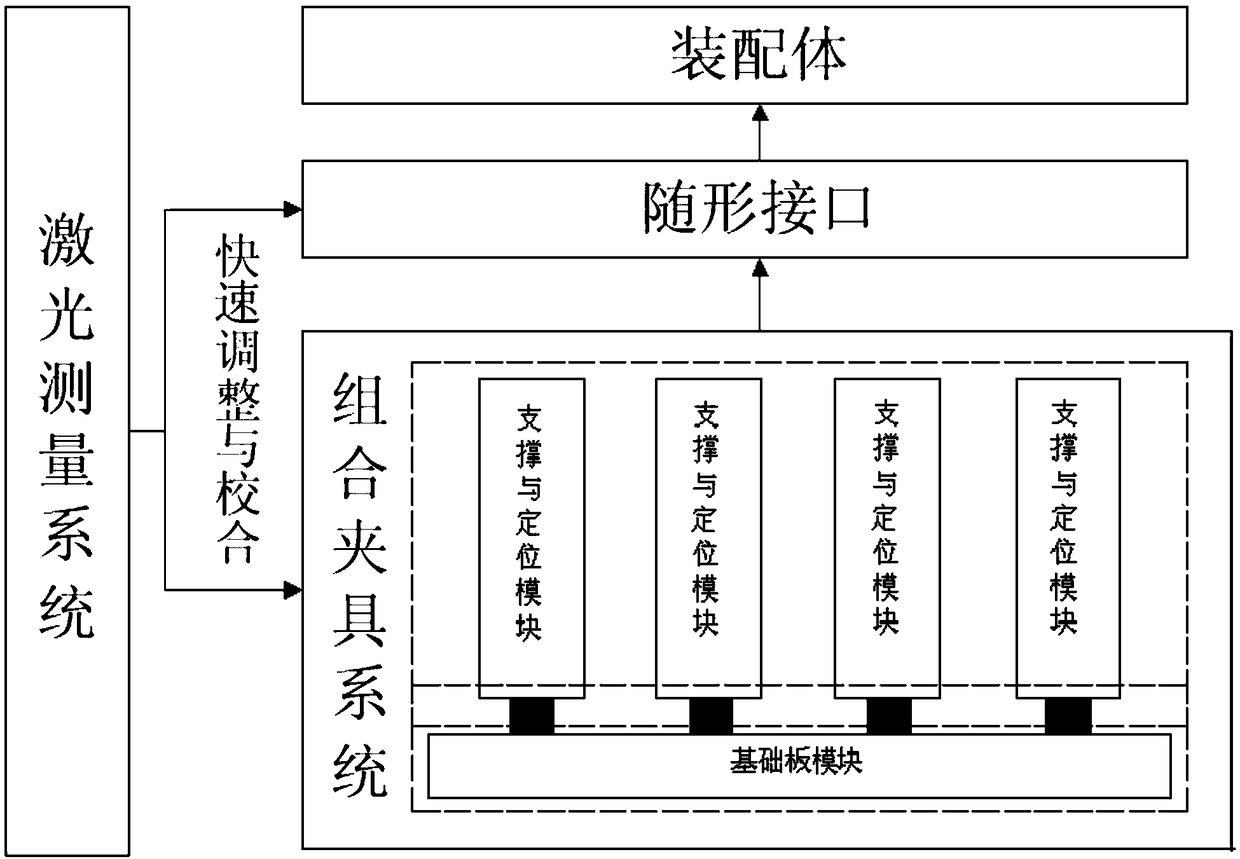

[0014] Step 1. Design the flexible composite fixture through UG three-dimensional modeling software: the flexible composite fixture is assembled with composite fixture components, including a base plate module, multiple support and positioning modules, and connecting keys; the support and positioning modules form a pair of cabins The positioning surface of component assembly, the base plate module and the support and positioning module are flexibly connected through connecting keys and positioning grooves; the support positioning module and the base plate module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com