Microcrystalline glass binder, preparation method thereof, superhard material grinding tool and preparation method thereof

A super-hard material abrasive tool and glass-ceramic technology, which is applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of unstable microcrystalline phase structure, reduced service life of abrasive tools, and high preparation costs, and achieve anti-bending Increased strength, extended service life, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

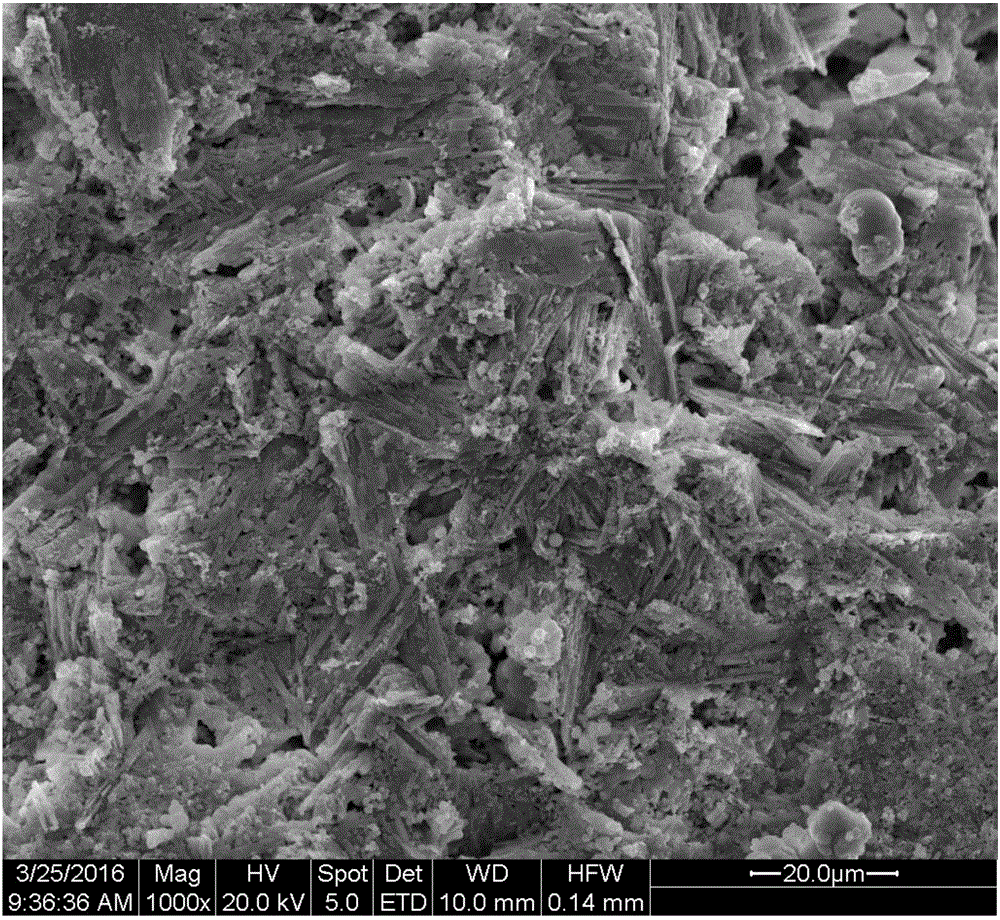

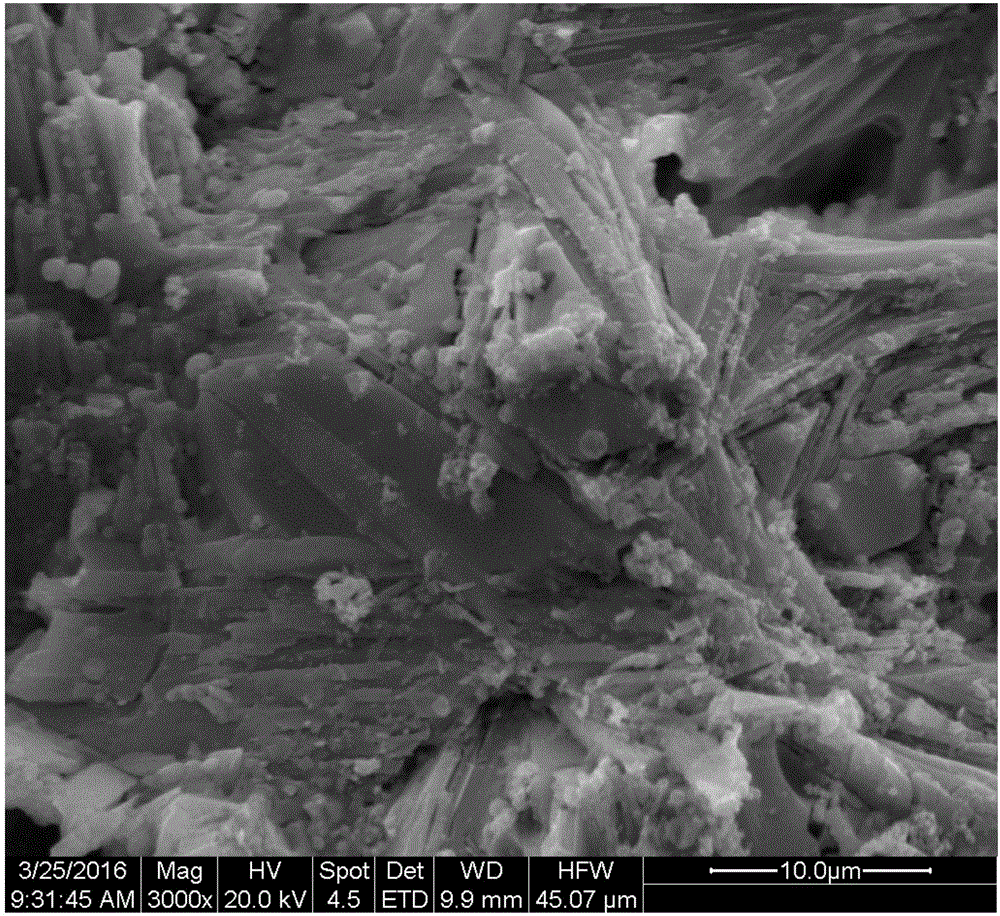

Image

Examples

Embodiment 1

[0033] In this embodiment, the glass-ceramic bonding agent is composed of the following components by mass percentage: 55% SiO 2 , 15% CaO, 10% K 2 O, 5% Na 2 O, 15% CaF 2 .

[0034] The preparation method of the glass-ceramic bonding agent in this embodiment includes the following steps:

[0035] 1) Mix the ingredients of the formula to obtain a mixture;

[0036] 2) After holding the mixture obtained in step 1) at a high temperature of 1350°C for 2 hours, a molten glass is obtained;

[0037] 3) The molten glass obtained in step 2) is water-quenched, wet ball milled for 4 hours, the slurry is dried at 95° C., then ground and passed through a 400-mesh sieve to obtain a glass-ceramic binder.

[0038] In this embodiment, the superhard material abrasive tool prepared by using the above-mentioned glass-ceramic bonding agent is a cubic boron nitride abrasive tool, and the preparation method is: taking 60 parts by weight of superabrasive cubic boron nitride and 40 parts by weight of micro The...

Embodiment 2

[0041] In this embodiment, the glass-ceramic bonding agent is composed of the following components by mass percentage: 65% SiO 2 , 5% CaO, 10% K 2 O, 15% Na 2 O, 5% CaF 2 .

[0042] The preparation method of the glass-ceramic bonding agent in this embodiment includes the following steps:

[0043] 1) Mix the ingredients of the formula to obtain a mixture;

[0044] 2) After holding the mixture obtained in step 1) at a high temperature of 1365°C for 2.5 hours, a molten glass is obtained;

[0045] 3) The molten glass obtained in step 2) is quenched with water, wet ball milled for 6 hours, the slurry is dried at 105° C., then ground and passed through a 400 mesh sieve to obtain a glass-ceramic binder.

[0046] In this embodiment, the superhard material abrasive tool prepared by using the above-mentioned glass-ceramic bonding agent is a cubic boron nitride abrasive tool, and the preparation method is: taking 55 parts by weight of superabrasive cubic boron nitride and 45 parts by weight of mic...

Embodiment 3

[0049] In this embodiment, the glass-ceramic bonding agent is composed of the following mass percentage components: 60% SiO 2 , 10% CaO, 1% K 2 O, 9% Na 2 O, 20% CaF 2 .

[0050] The preparation method of the glass-ceramic bonding agent in this embodiment includes the following steps:

[0051] 1) Mix the ingredients of the formula to obtain a mixture;

[0052] 2) After the mixture obtained in step 1) is kept at a high temperature of 1380°C for 3 hours, a molten glass is obtained;

[0053] 3) The molten glass obtained in step 2) is water-quenched, wet ball milled for 5 hours, the slurry is dried at 100° C., then ground and passed through a 400 mesh sieve to obtain a glass-ceramic binder.

[0054] In this embodiment, the superhard material abrasive tool prepared by using the above-mentioned glass-ceramic bonding agent is a cubic boron nitride abrasive tool, and the preparation method is: taking 65 parts by weight of superabrasive cubic boron nitride and 35 parts by weight of micro The cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com