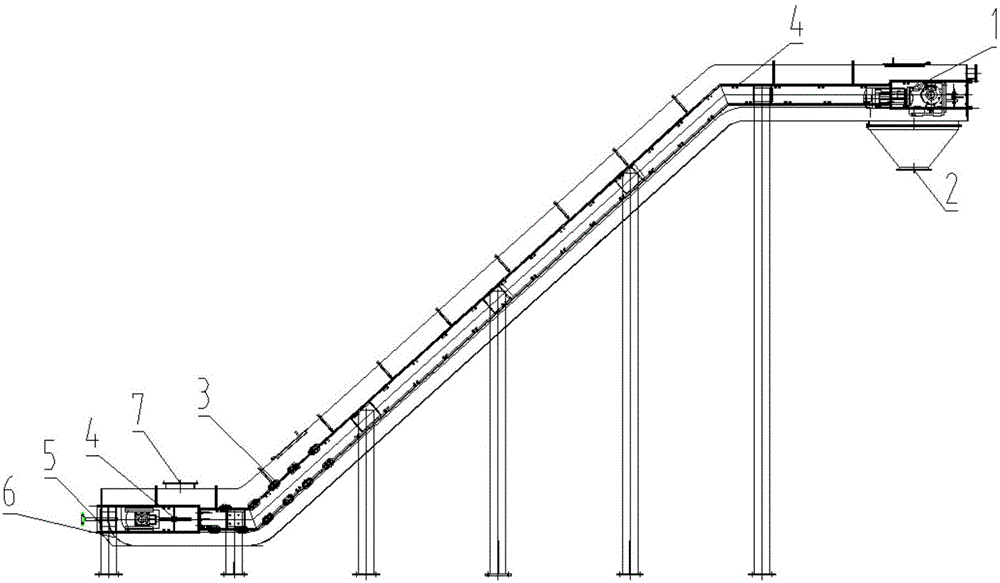

Large-dip-angle board slot conveyer for conveying high-viscosity and high-humidity materials

A conveyor with a large inclination angle technology, which is applied in the field of large inclination trough conveyors, can solve the problems of large floor space and achieve the effects of ensuring continuity, saving equipment floor space and material usage, and ensuring lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

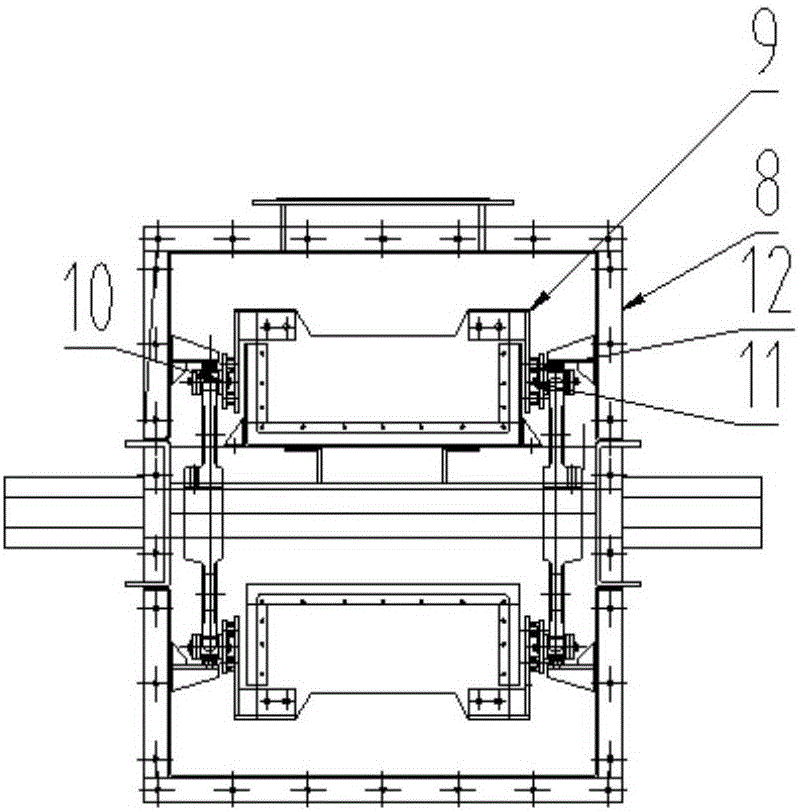

[0028] The patent of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

[0029] Before the trough conveyor runs, the distance between the arc-shaped tail plate 7 and the scraper 9 must be adjusted through the distance adjustment structure 5 at first. Utilize the cooperation of the hand wheel and the lead screw arranged on the arc tail plate, after adjusting the distance between the arc tail plate and the scraper to a proper level, fix it with the positioning pin. The spacing is preferably 2-3mm. Smaller spacing reduces leakage.

[0030] At the same time, manually adjust the tension structure 4 through the double chains installed on both sides of the chain at the tail end of the machine to keep the chain 3 in a tensioned state to ensure the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com