Falling mechanism capable of controlling time and quantity

A blanking mechanism and time-controlled technology, used in conveyors, conveyor objects, non-mechanical conveyors, etc., can solve the problems of system failure, expensive equipment, damage, etc., to achieve long service life, simple structure, prevent The effect of a power outage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] This example is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to those of this experimental example are within the protection scope of the present invention.

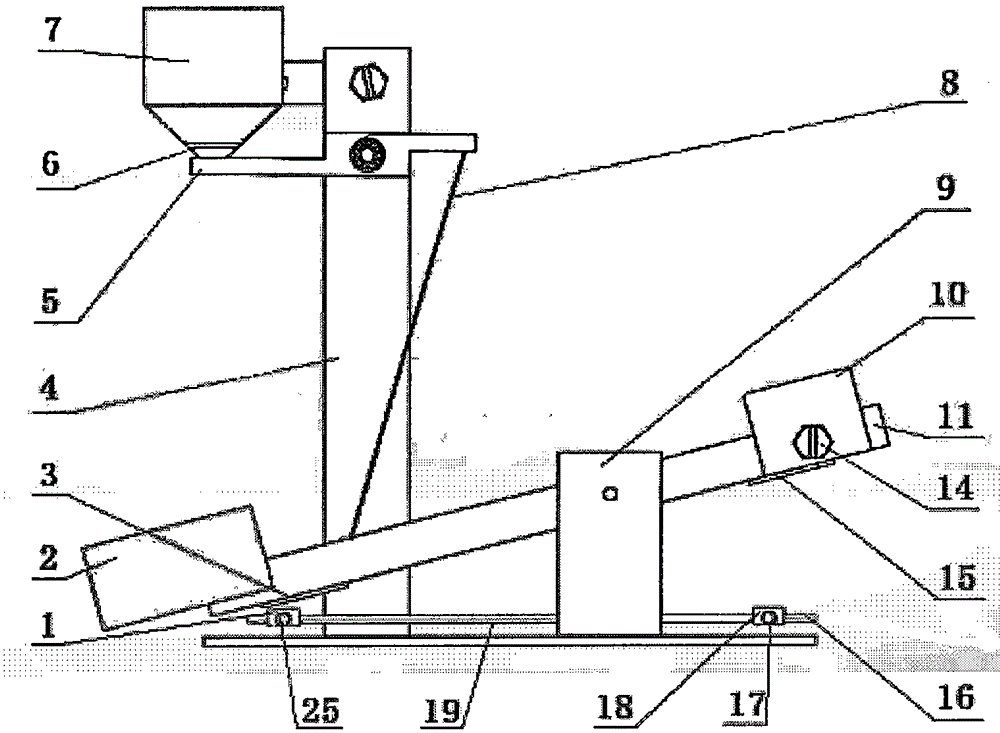

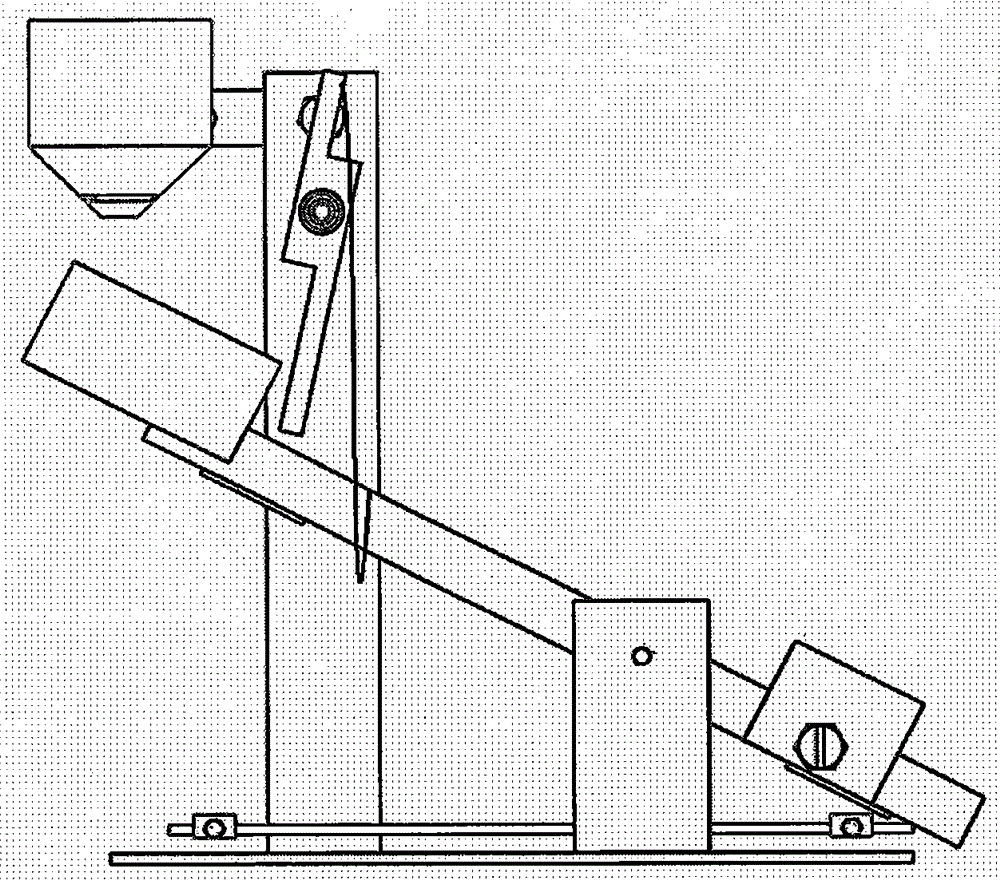

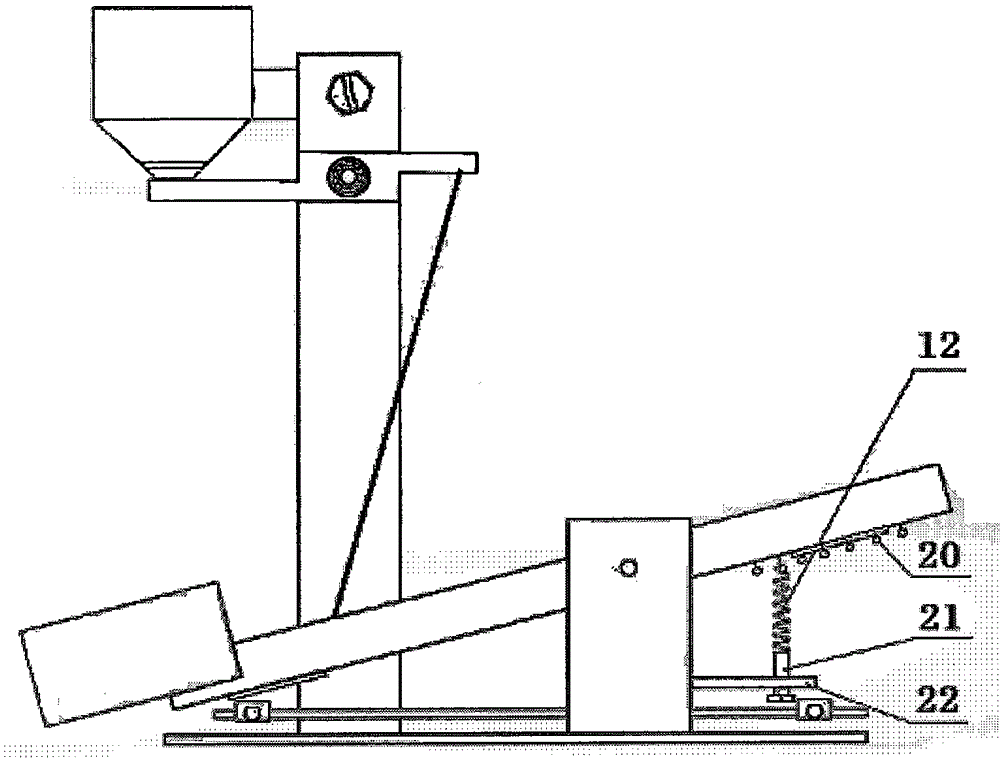

[0017] Please refer to the attached Figures 1 to 9 , the time-controllable and volume-controllable blanking mechanism of the application of the present invention:

[0018] The left end of the lever 11 fixes the feeder 2, and the right end is a weight 10 or an adjustable spring-12, wherein one side of the weight has a fastening bolt-14, which can be adjusted to a fixed position loosely, and can be fixed tightly; the adjustable spring-12 There is an adjusting bolt at one end, and the size of the elastic force is adjusted by turning the bolt up and down, and the other end of the spring can be hung on different hooks 20 on the lever 11 to realize the change of the arm of force.

[0019] The lower opening of the stocker 7 has a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com