Wood plate airing and rod putting machine

A technology for the board and wood industry, which is applied in the field of wood board drying and laying machines, can solve the problems of large labor and low efficiency of workers, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

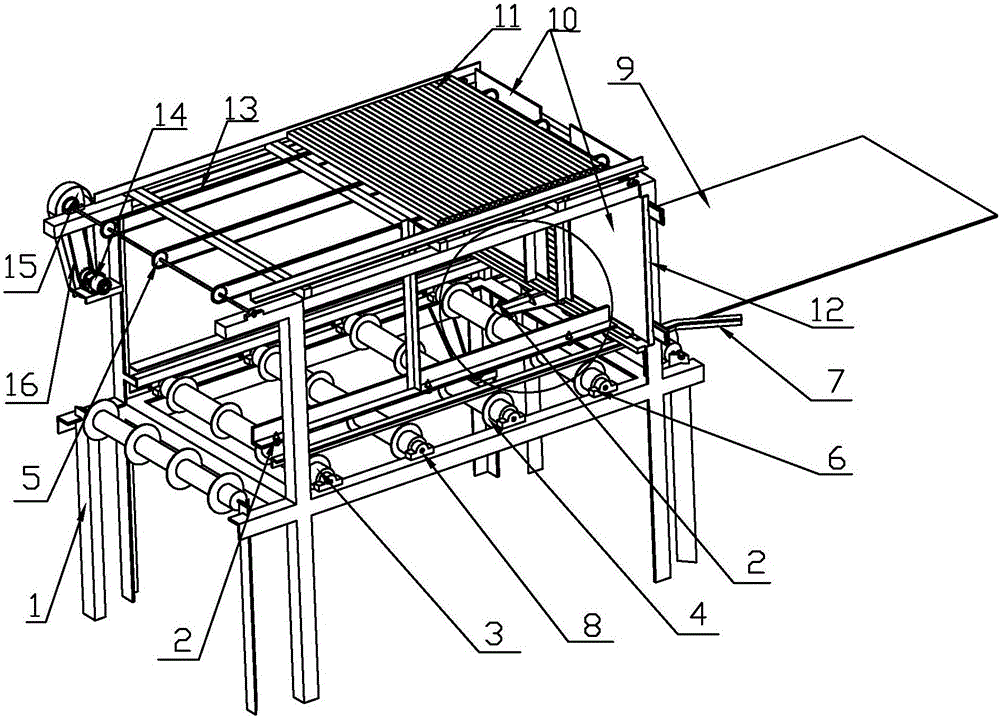

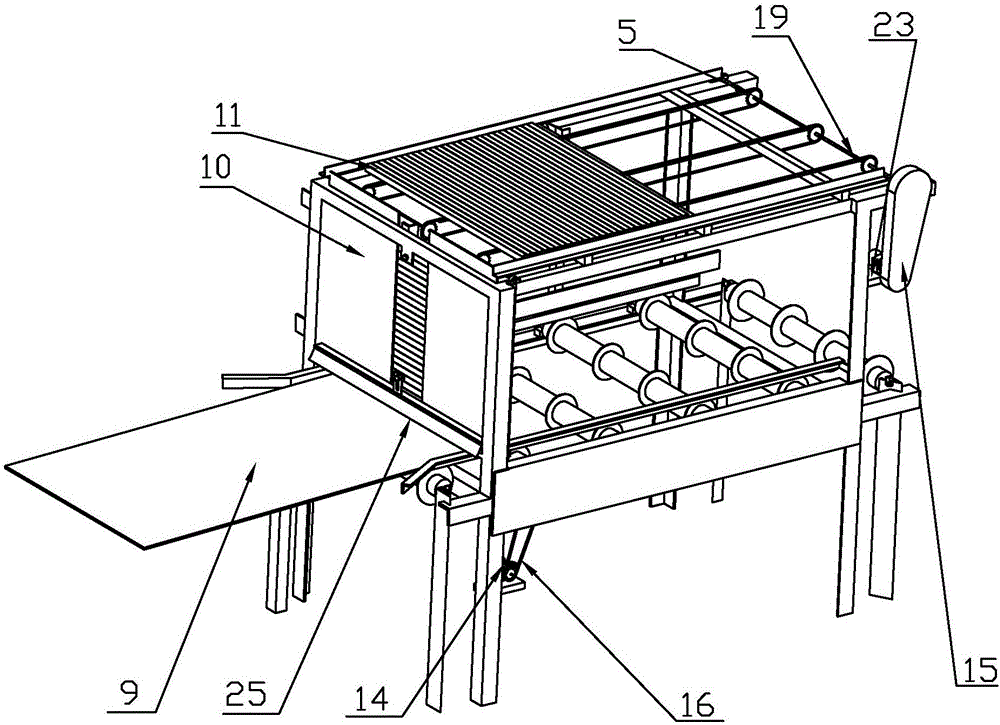

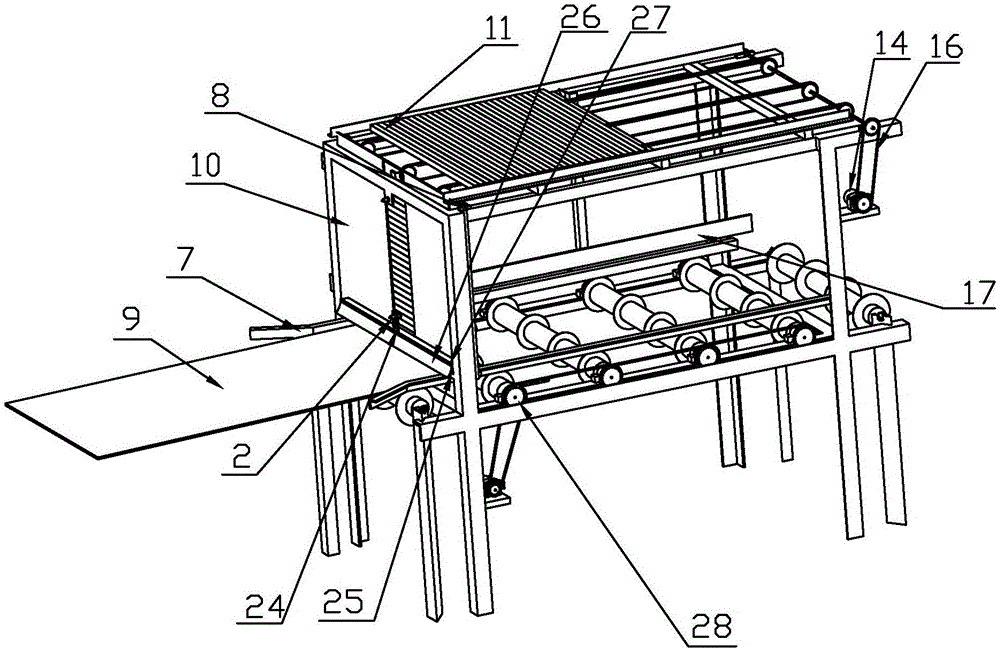

[0024] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0025] A wood panel drying rod machine, including a frame 1, a photoelectric sensor 2, a roller 3, a placement board 10, a square rod 11, a chain support board 13, a sensor placement rack 17, a connecting rod shaft 19, a cylinder 20, a discharge Push plate 21, the top of the frame 1 is provided with several bearing blocks 6, the two sides of the top of the frame 1 are respectively provided with a connecting rod shaft 19, and one end of the connecting rod shaft 19 is provided with a sprocket 5, and the sprocket 5 Link to each other with the motor 14 of lower side by chain 16, described motor 14 is arranged on the motor support plate 23, and motor support plate 23 is welded on the frame 1, and described motor 14 provides power for chain 16, and described connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com