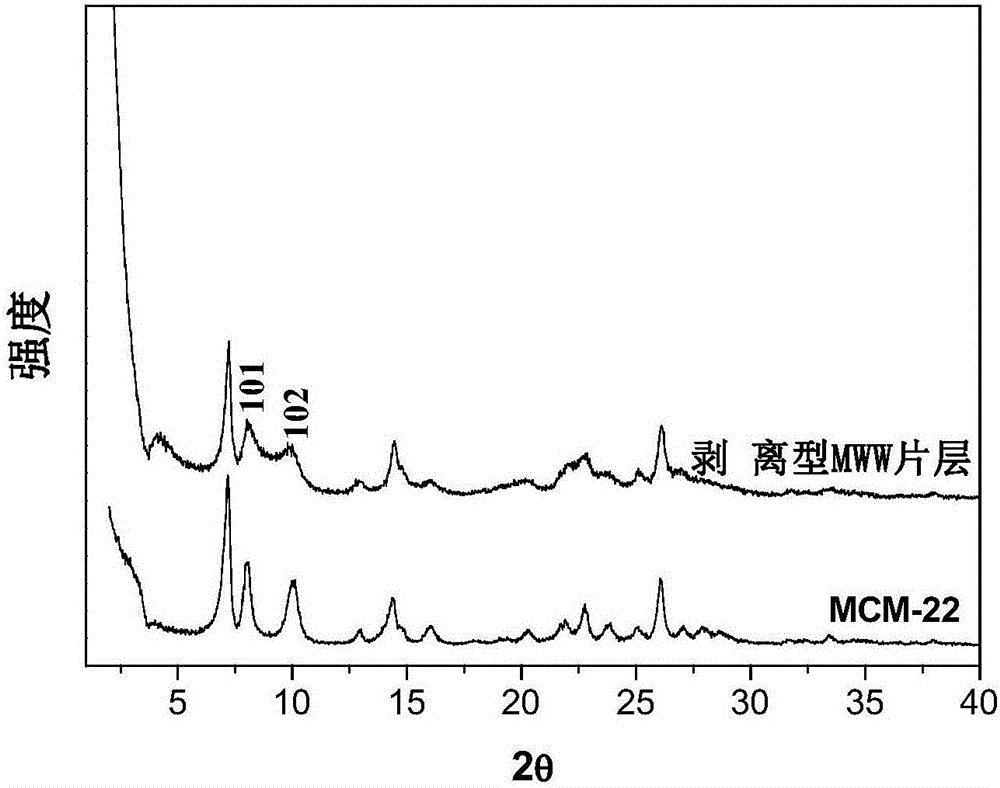

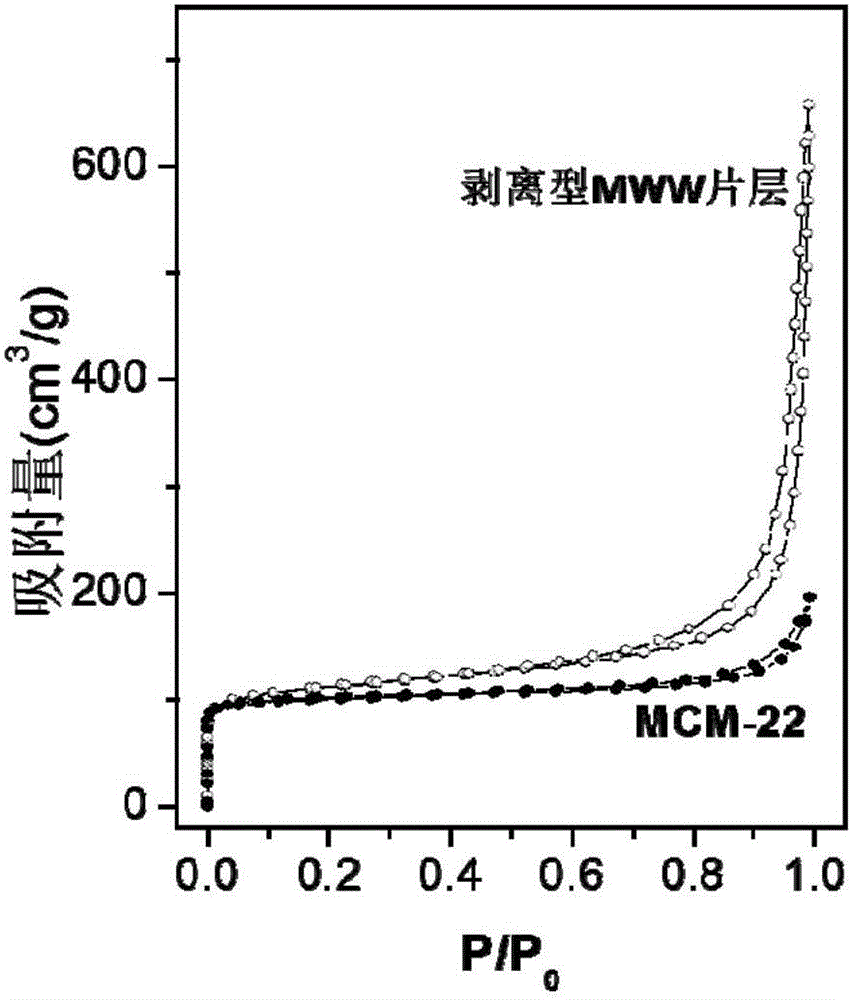

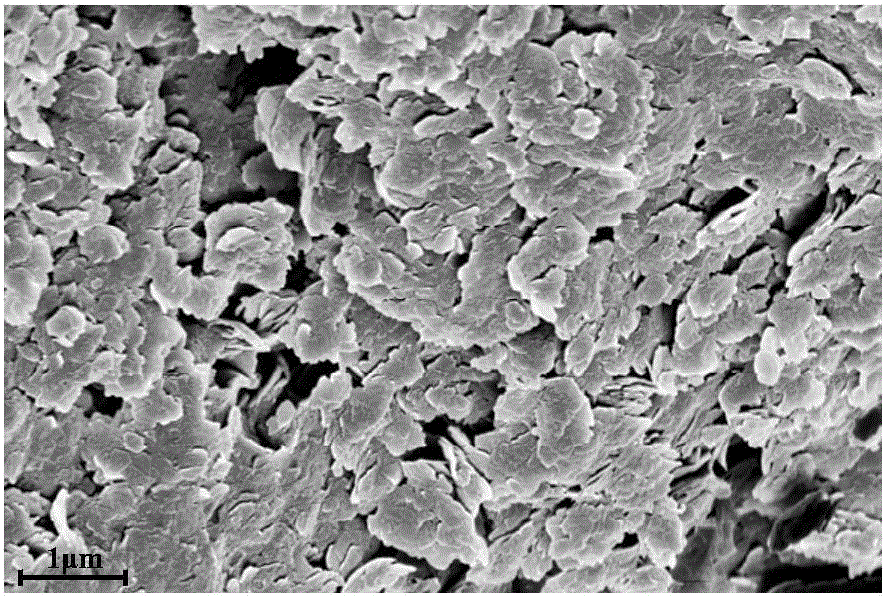

Dynamic hydrothermal synthesis method of exfoliated type MWW lamellar molecular sieve

A dynamic hydrothermal, exfoliating technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of complicated steps, high cost, difficult price, etc., and achieve the effect of low price and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. According to the molar ratio of SiO 2 / Al 2 o 3 =50, OH / SiO 2 =0.14, Na / SiO 2 =0.14, HMI / SiO 2 =0.35,H 2 O / SiO 2 =45, CPAB / HMI=0.25, weigh 0.21g of sodium metaaluminate, 0.24g of sodium hydroxide, 6.22g of silica sol, 7g of CPAB, 1.45g of HMI, and 33.55mL of deionized water.

[0028] 2. Dissolve sodium hydroxide in 22.37mL deionized water to prepare sodium hydroxide aqueous solution, dissolve CPAB in 11.18mL deionized water to prepare CPAB aqueous solution; add HMI to the prepared CPAB aqueous solution, and stir for 5 hours at room temperature , to obtain a structure-directing agent mixture.

[0029] 3. Add sodium metaaluminate to the prepared sodium hydroxide aqueous solution under stirring. After the sodium metaaluminate is completely dissolved, add the silica sol and the structure-directing agent mixture in step 2 drop by drop, and then use Adjust the pH to 13.7-13.8 with 6 mol / L sodium hydroxide aqueous solution, and stir for 30 minutes at room temperatur...

Embodiment 2

[0034] 1. According to the molar ratio of SiO 2 / Al 2 o 3 =30, OH / SiO 2 =0.18, Na / SiO 2 =0.18, HMI / SiO 2 =0.5,H 2 O / SiO 2 =45, CPAB / HMI=0.25, weigh 0.28g of sodium metaaluminate, 0.42g of sodium hydroxide, 5.04g of silica sol, 5.25g of CPAB, 1.68g of HMI, and 24.19mL of deionized water.

[0035] 2. Dissolve sodium hydroxide in 16.13mL deionized water to prepare sodium hydroxide aqueous solution, and dissolve CPAB in 8.06mL deionized water to prepare CPAB aqueous solution; add HMI to the prepared CPAB aqueous solution, and stir for 5 hours at room temperature , to obtain a structure-directing agent mixture.

[0036] 3. Add sodium metaaluminate to the prepared sodium hydroxide aqueous solution under stirring. After the sodium metaaluminate is completely dissolved, add the silica sol and the structure-directing agent mixture in step 2 drop by drop, and finally Use 6 moles per liter of sodium hydroxide solution to adjust the pH of the mixture to 13.7-13.8, and stir for 30 ...

Embodiment 3

[0040] 1. According to the molar ratio of SiO 2 / Al 2 o 3 =100, OH / SiO 2 =0.2, Na / SiO 2 =0.2, HMI / SiO 2 =0.3,H 2 O / SiO 2 =50, CPAB / HMI=0.2, weigh 0.09g of sodium metaaluminate, 0.32g of sodium hydroxide, 5.72g of silica sol, 7.86g of CPAB, 1.14g of HMI, and 30.35mL of deionized water.

[0041] 2. Dissolve sodium hydroxide in 20.23mL deionized water to prepare sodium hydroxide aqueous solution, dissolve CPAB in 10.12mL deionized water to prepare CPAB aqueous solution; add HMI to the prepared CPAB aqueous solution, and stir for 8 hours at room temperature , to obtain a structure-directing agent mixture.

[0042] 3. Add sodium metaaluminate to the prepared sodium hydroxide aqueous solution under stirring. After the sodium metaaluminate is completely dissolved, add the silica sol and the structure-directing agent mixture in step 2 drop by drop, and finally Use 6 moles per liter of sodium hydroxide solution to adjust the pH of the mixture to 13.7-13.8, and stir for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com