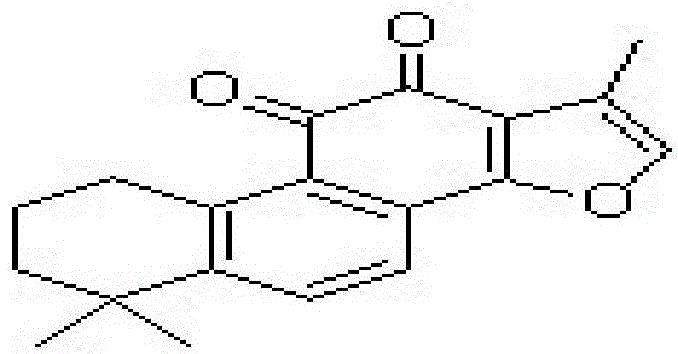

Method for extracting tanshinone IIA

An extraction method and technology of tanshinone, which is applied in the field of extraction of the target component tanshinone IIA in Danshen medicinal materials, can solve the problems of high explosion-proof requirements for equipment and facilities, low production safety factor, complex process, etc., and achieve targeted separation and safe production and operation The effect of low coefficient and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

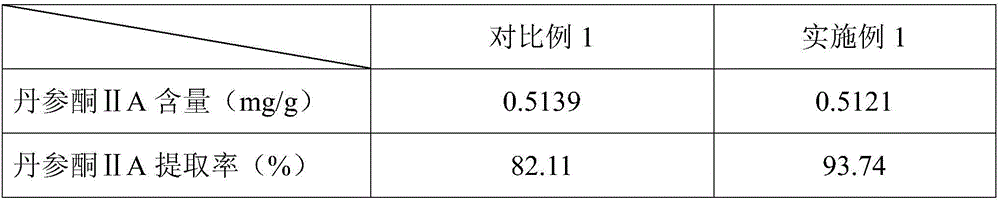

Embodiment 1

[0046] The present embodiment provides a kind of extraction method of tanshinone IIA, described method is:

[0047] (1) Grind the salvia miltiorrhiza medicinal material until it passes through a 5-mesh sieve, and the moisture content is 2 In the barrel of the extraction device, measure ethanol with a concentration of 95wt% as an entrainer, the amount of the entrainer is 1:6 (W / V), and CO 2 As the extraction agent, set the equipment parameters as follows: the pressure of the extraction tank is 32MPa, and the temperature is 60°C; the separation pressure of the first separation tank is 13MPa, and the temperature is 50°C; the separation pressure of the second separation tank is 6MPa, and the temperature is 45°C ; The flow rate of the extractant is 26L / h; the extraction time is 90min; 1 time of supercritical extraction is carried out to obtain the extract;

[0048] (2) Concentrate the extract obtained in step (1) by rotary evaporation at 50° C. to obtain Tanshinone IIA.

[0049] T...

Embodiment 2

[0056] The present embodiment provides a kind of extraction method of tanshinone IIA, described method is:

[0057] (1) Grind the salvia miltiorrhiza medicinal material until it passes through a 5-mesh sieve, and the moisture content is 2 In the barrel of the extraction device, measure ethanol with a concentration of 95wt% as an entrainer, the amount of the entrainer is 1:5 (W / V), and CO 2 As the extraction agent, set the equipment parameters as follows: the pressure of the extraction tank is 30MPa, and the temperature is 58°C; the separation pressure of the first separation tank is 12MPa, and the temperature is 48°C; the separation pressure of the second separation tank is 6MPa, and the temperature is 43°C ; The flow rate of the extractant is 16L / h; the extraction time is 90min; 1 time of supercritical extraction is carried out to obtain the extract;

[0058] (2) Concentrate the extract obtained in step (1) by rotary evaporation at 50° C. to obtain Tanshinone IIA.

[0059] T...

Embodiment 3

[0066] The present embodiment provides a kind of extraction method of tanshinone IIA, described method is:

[0067] (1) Grind the salvia miltiorrhiza medicinal material until it passes through a 5-mesh sieve, and the moisture content is 2 In the barrel of the extraction device, measure ethanol with a concentration of 95wt% as an entrainer, the amount of the entrainer is 1:10 (W / V), and CO 2 As the extraction agent, set the equipment parameters as follows: the pressure of the extraction tank is 30MPa, and the temperature is 55°C; the separation pressure of the first separation tank is 10MPa, and the temperature is 45°C; the separation pressure of the second separation tank is 6MPa, and the temperature is 40°C ; The flow rate of the extractant is 23L / h; the extraction time is 90min; 1 time of supercritical extraction is carried out to obtain the extract;

[0068] (2) Concentrate the extract obtained in step (1) by rotary evaporation at 50° C. to obtain Tanshinone IIA.

[0069] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com