Fruit extract and application

A fruit extraction and extract technology, which is applied to the preparation and application of fruit extracts, can solve the problems of poor flavor compatibility and fusion, difficult stability control, residual smoke, etc. stimulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

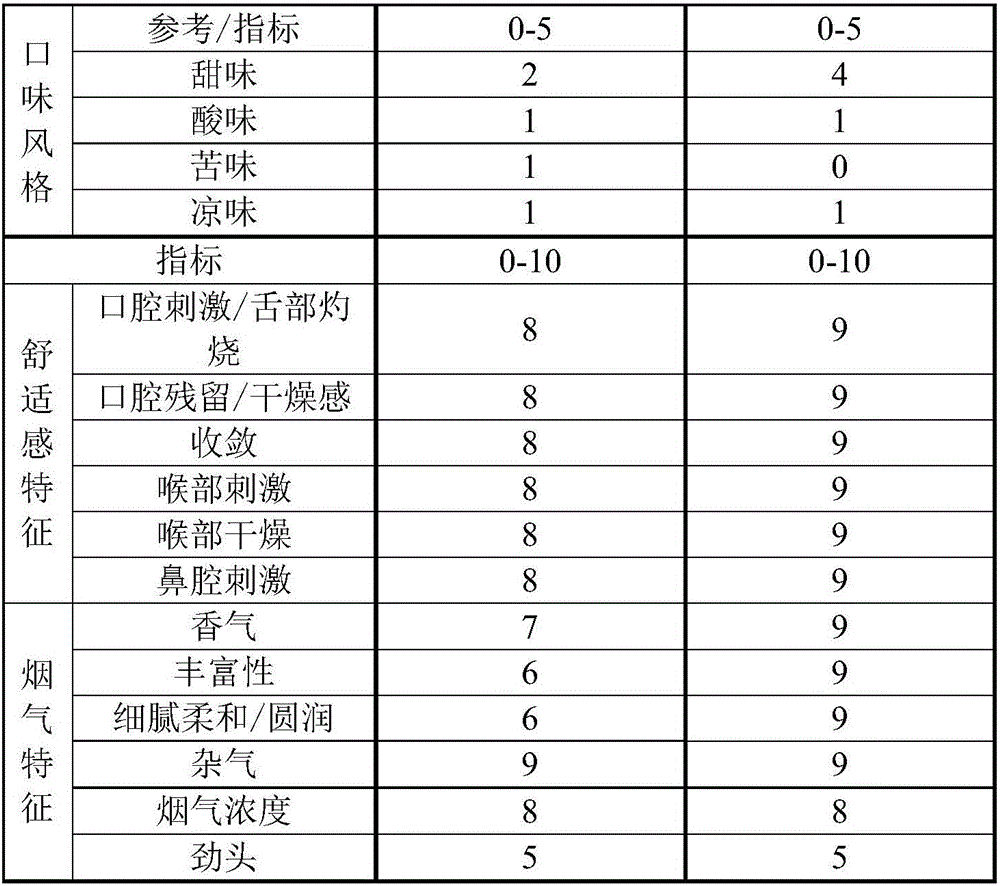

[0044] Embodiment 1 fruit is cherry

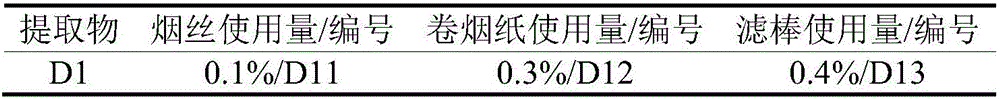

[0045] Preparation of Extract C1 and Extract D1

[0046] (1) After washing the fresh cherries, crush them with a crusher for 10 minutes, and take 1000 grams of cherry pulp for subsequent use;

[0047] (2) Get 50kg of Luzhou-flavor liquor fermented 10 days before the fermented material, add the above-mentioned cherry pulp in the fermenter, mix evenly and continue to ferment for 12 days;

[0048] (3) Add 100 kg of 95% ethanol, reflux extraction for 6 hours, filter to obtain filtrate A1, and keep the filter residue for subsequent use;

[0049] (4) Add 100kg of mixed solvent of ethanol and propylene glycol (volume ratio is 1:1) in filter residue, extract for 10 hours, filter to obtain filtrate B1;

[0050] (5) Concentrate the filtrate A1 under reduced pressure at a pressure of -0.09±0.01MPa and a temperature of 40±2°C, so that the specific gravity of the concentrated solution reaches 0.900±0.005g / cm 3 , to obtain the extract C1;

[0051] ...

Embodiment 2

[0088] Example 2 The fruit is seabuckthorn

[0089] Preparation of Extract C2 and Extract D2

[0090] (1) After the seabuckthorn fruit is air-cleaned, pulverize it to 50 mesh with a pulverizer, and take 1000 grams of seabuckthorn powder for subsequent use;

[0091] (2) Get 50kg of Luzhou-flavor liquor fermented 15 days before the fermented material, add the seabuckthorn powder to the fermenter, mix well and continue to ferment for 15 days;

[0092] (3) Add 100kg of 95% ethanol, reflux extraction for 6 hours, filter to obtain filtrate A2, and keep the filter residue for subsequent use;

[0093] (4) Add 100kg of mixed solvent of ethanol and propylene glycol (volume ratio is 1:1) in the filter residue, extract for 10 hours, filter to obtain filtrate B2;

[0094] (5) Concentrate the filtrate A2 under reduced pressure at a pressure of -0.10±0.01MPa and a temperature of 40±2°C, so that the specific gravity of the concentrated solution reaches 0.950±0.005g / cm3 to obtain the extra...

Embodiment 3

[0131] Embodiment 3 fruit is mulberry

[0132] Preparation of Extract C3 and Extract D3

[0133] (1) After the fresh mulberry is washed, break it with a crusher for 10 minutes, and take 1000 grams of mulberry pulp for subsequent use;

[0134] (2) Get 50kg of Luzhou-flavor liquor fermented fermented material 15 days ago, add the above-mentioned mulberry pulp in the fermenter, mix and continue to ferment for 16 days;

[0135] (3) Add 100kg of 95% ethanol, reflux extraction for 6 hours, filter to obtain filtrate A3, and keep the filter residue for subsequent use;

[0136] (4) Add 100kg of mixed solvent of ethanol and propylene glycol (volume ratio is 1:1) in the filter residue, extract for 12 hours, filter to obtain filtrate B3;

[0137] (5) Concentrate the filtrate A3 under reduced pressure at a pressure of -0.09±0.01MPa and a temperature of 45±2°C, so that the specific gravity of the concentrated solution reaches 0.900±0.005g / cm 3 , to obtain extract C3;

[0138] (6) Conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com