A film-covered aerobic fermentation cycle device and cycle method

An aerobic fermentation and circulation device technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problem of deodorization, emission reduction effect limitation, uneven temperature and humidity distribution, fermentation Insufficient and other problems, to reduce greenhouse gas emissions, avoid excessive consumption, and achieve good fermentation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

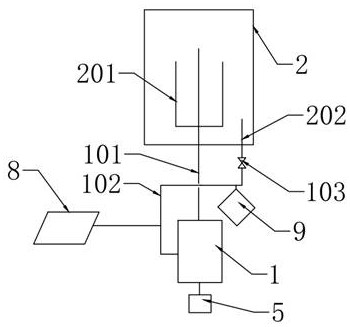

[0071] The fermentation enters the third stage, the high temperature stage is continued, and the temperature of the stacking material is greater than or equal to 70 °C, and the first control valve 103 is fully opened to make the

Embodiment 2

[0083] The fermentation enters the third stage, the high temperature stage continues, and the temperature of the stacking material is ≥ 70 ° C, and the first control valve 103 is fully opened to make the

Embodiment 3

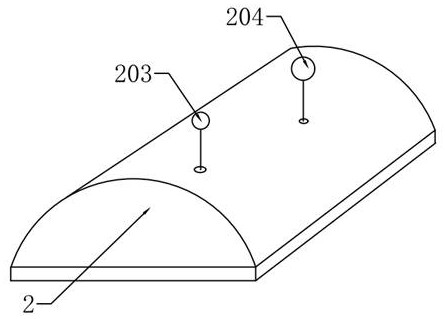

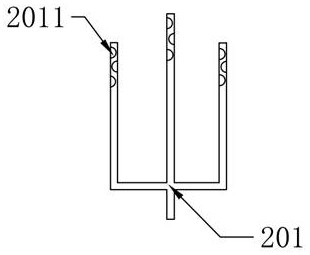

[0090] A membrane covered aerobic fermentation cycle device, as shown in Figure 5.

[0098] The fermentation enters the third stage, the high temperature stage continues, and the temperature of the stacking material is ≥ 70 °C, and the first control valve 103 is fully opened to make the

[0100] When the temperature of the stacking material in the first fermentation bin 2 is ≥60 ° C, the air humidity between the waterproof and moisture-permeable membrane and the stacking material is greater than or equal to 95%

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com