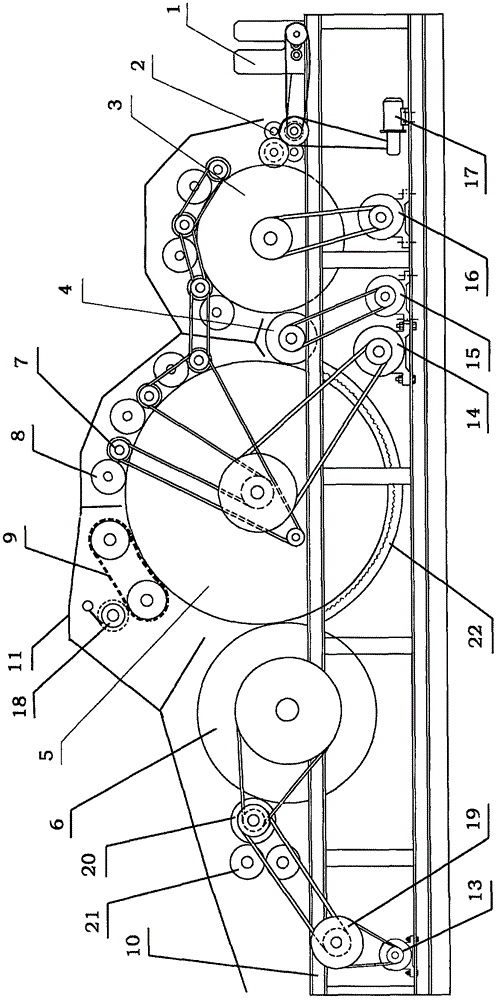

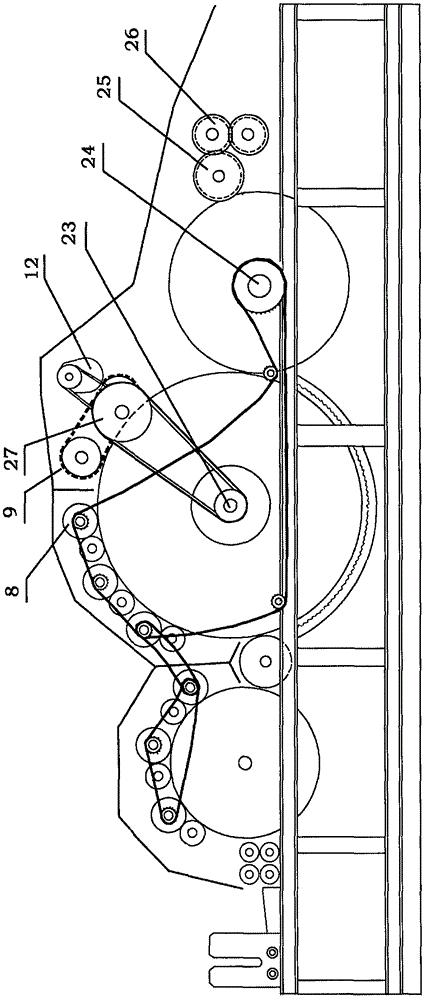

China hemp fiber one-step fiber forming and carding machine

A technology of hemp fiber and carding machine, which is applied in fiber processing, deburring devices, textiles and papermaking, etc. It can solve the problems of long storage time of primary carding raw materials, difficulty in producing splitting degree, and excessive moisture loss of fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing; Equipment is made of car wall panel 10 and equipment body. The equipment body is composed of the feeding part, the first carding area, the second carding area and the web forming part. There is feeding motor 17 below the car wall panel 10, and the hemp roll roller 1 is housed at the car wall panel rear portion, and the front portion of the hemp roll roller has a feed roller 2. A cylinder A motor 16 is arranged below the car wall plate, cylinder A is provided above the cylinder A motor, and three work rolls and three transfer rolls are provided above the cylinder A. There is a cylinder B5 in front of the cylinder A. There is a cylinder B motor 14 at the bottom of the cylinder B. There are three work rolls 8 on the top of the cylinder B, and three transfer rolls 7 between the work rolls. There is a cover plate 9 at the front portion of the work roll, and a large brush 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com