Multi-storey parking method and device

A parking device and underlying technology, which is applied in the direction of buildings, building types, buildings, etc. where cars are parked, can solve problems such as reducing the service life of stressed parts, hidden safety hazards, and high noise, so as to ensure stability, high reliability, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

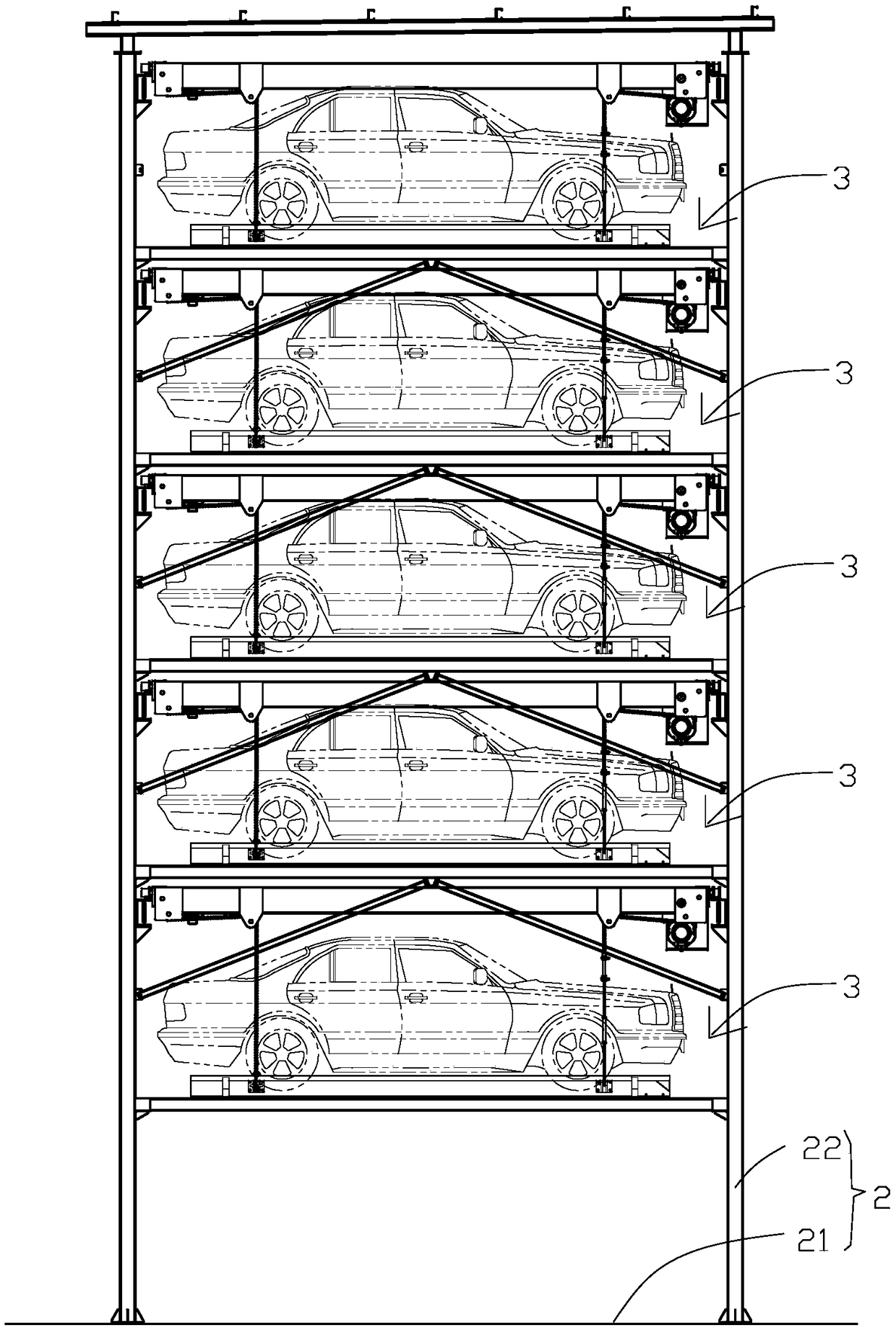

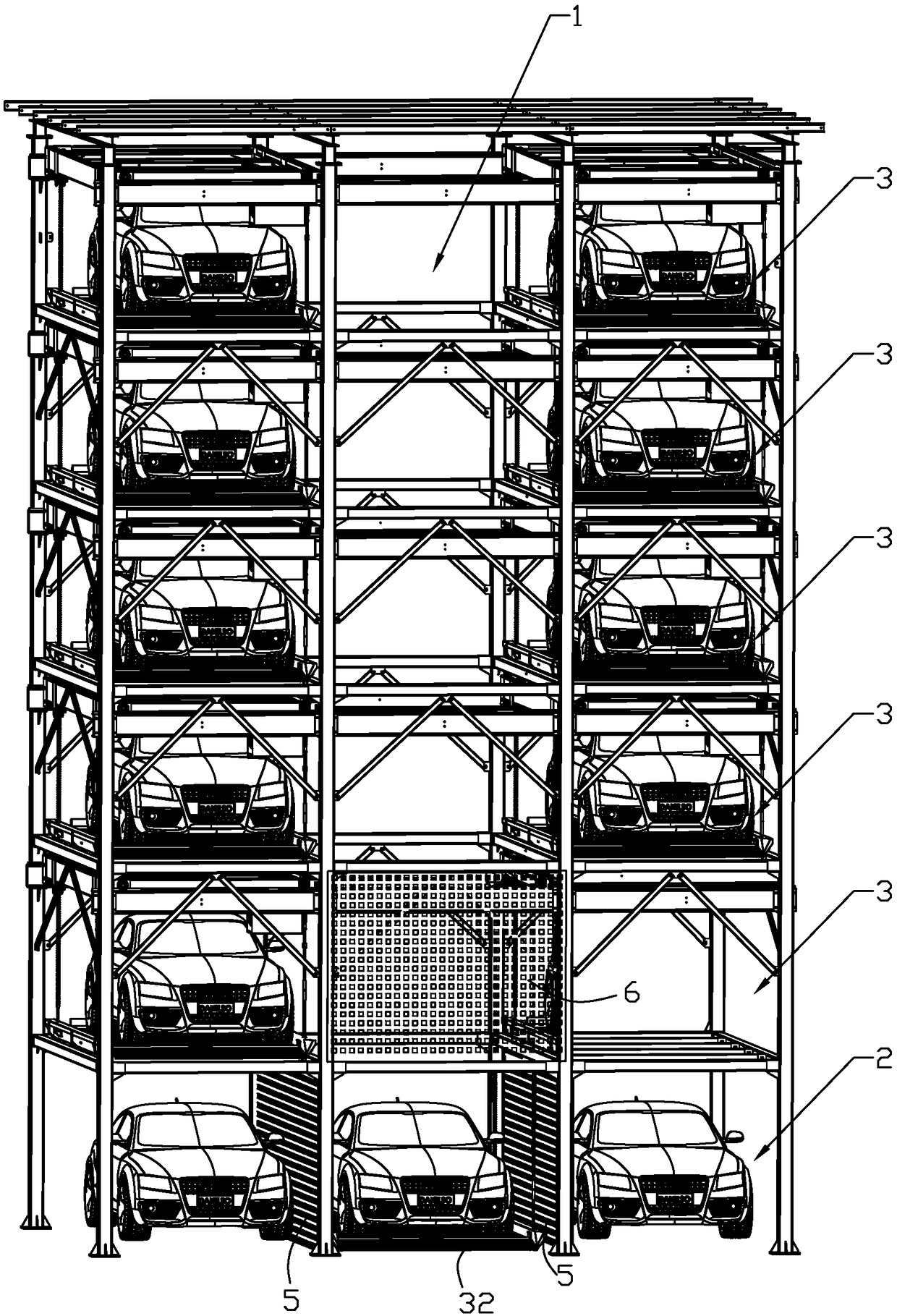

[0042] Such as Figure 1-12 Shown, a kind of multi-storey parking device (hereinafter referred to as parking device), comprises the channel base surface 11 that vehicle can drive in and out longitudinally, the two sides of channel base surface 11 are symmetrically provided with bottom parking unit 2, each bottom parking unit 5 (can be several of 2, 3, 4, 5, 6, 7...N) upper floor parking units 3 are arranged in turn above the base surface, and a parking space for vehicles to go up and down repeatedly is formed between the two rows of parking units above the base surface. Lifting passage 1, the parking device also includes a PLC control system (not shown in the figure), and the PLC control system ensures that only one vehicle performs lifting movement in the lifting passage 1 at a time.

[0043] Such as Figure 1-3 As shown, a protective fence 5 is provided between the lifting passage 1 and the bottom parking unit 2, and a protective door 6 that can be repeatedly raised and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com