Riser column group vibration anti-collision and power generation device and method

A power generation device, standpipe technology, applied in the direction of generator/motor, drill pipe, casing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

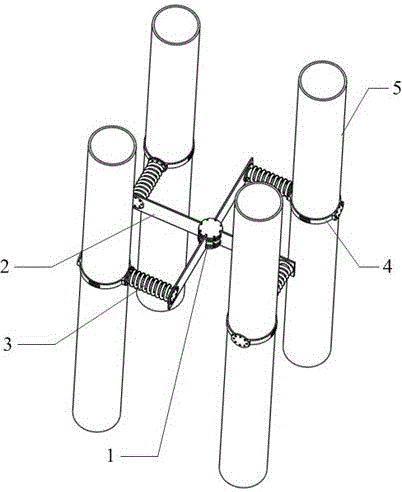

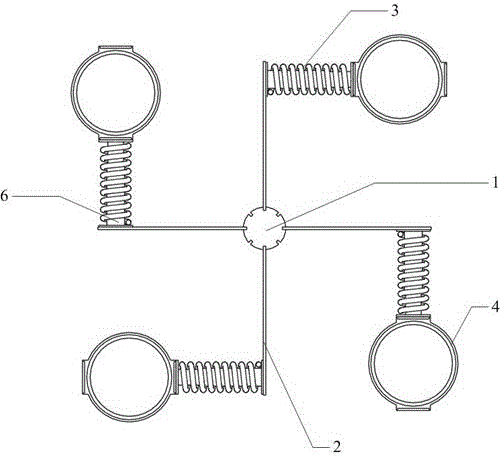

[0034] During actual installation, according to the number of 5 risers of the riser 5 column group and the relative position, choose to install them in an array or as a basic unit, and determine the number of 2 piezoelectric sheet integrated boards connected to a central steering wheel 1.

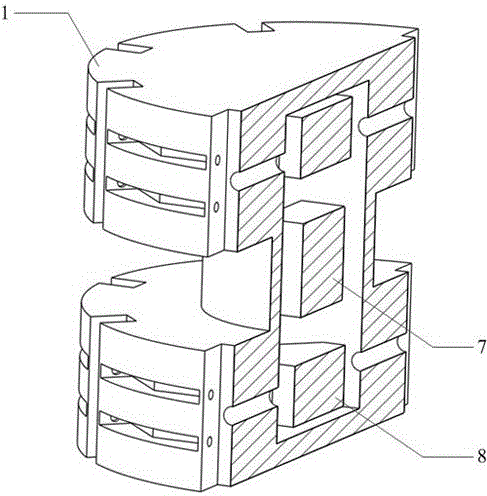

[0035] When installing a single basic unit, first set the fastening sleeve 4 on the outer wall of the riser 5, and then fix the fixed flange 9 at one end of the fastening sleeve 4 with the fixed flange 9 at one end of the nested telescopic tube 6 through bolt connection, The spring 3 is set outside the nested telescopic tube 6, and the fixed flange 9 at the other end of the nested telescopic tube 6 is engaged and fixed. Next, one end of the piezoelectric sheet integrated board 2 provided with the bolt holes required for connection with the fixed flange 9 is connected to the fixed flange 9 at the free end of the nested telescopic tube 6 through bolts, and the piezoelectric sheet integrated bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com