Hydraulic throwing-in and pulling type sand-draining coal dust-draining gas production device and method

A gas recovery and hydraulic technology, applied in the direction of production fluid, earth square drilling, non-volume pump, etc., can solve problems such as eccentric wear of the pumping drive rod and casing, unsuitable for drainage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In a preferred embodiment of the present invention, the hydraulic throwing-and-fishing-type sand-discharging and pulverized-coal gas extraction device includes the following devices:

[0083] 1. Ground installation

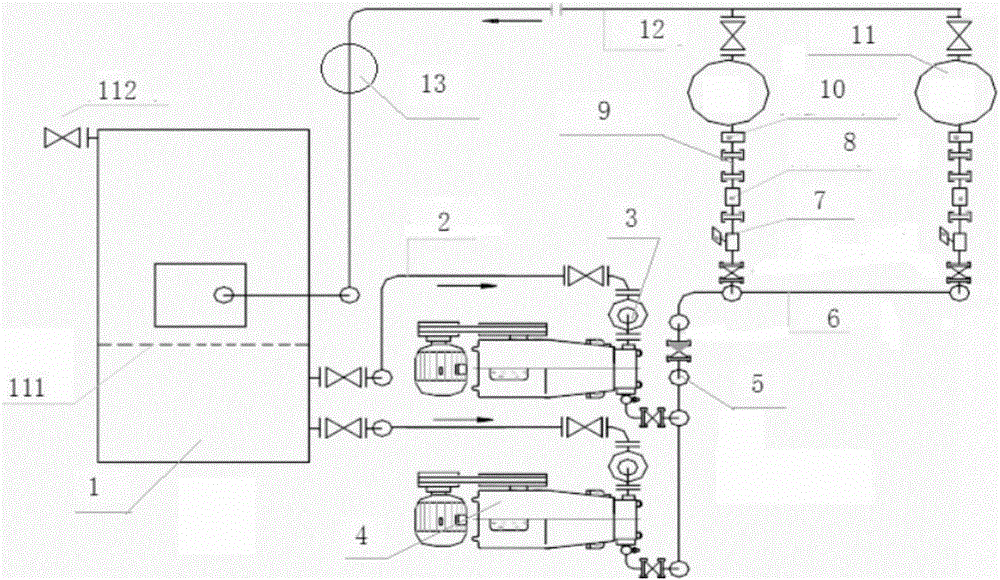

[0084] As the power of the whole device, the ground device is the key to ensure the smooth operation of the whole device. The composition of the ground device described in this embodiment is as follows: figure 1 As shown, including the following structure:

[0085] 1.1 Sedimentation tank 1

[0086] The settling tank 1 is a step-by-step settling tank, which is a device for returning liquid to deposit coal powder and sand particles. There are multiple internal partitions 111 in the tank, and multiple partition tanks are formed in the tank. The upper part of the sedimentation tank 1 is provided with an overflow port 112, and the tank body is provided with a fluid outlet at the last stage of the separator tank; a fluid inlet is provided at the middle of the ...

Embodiment 2

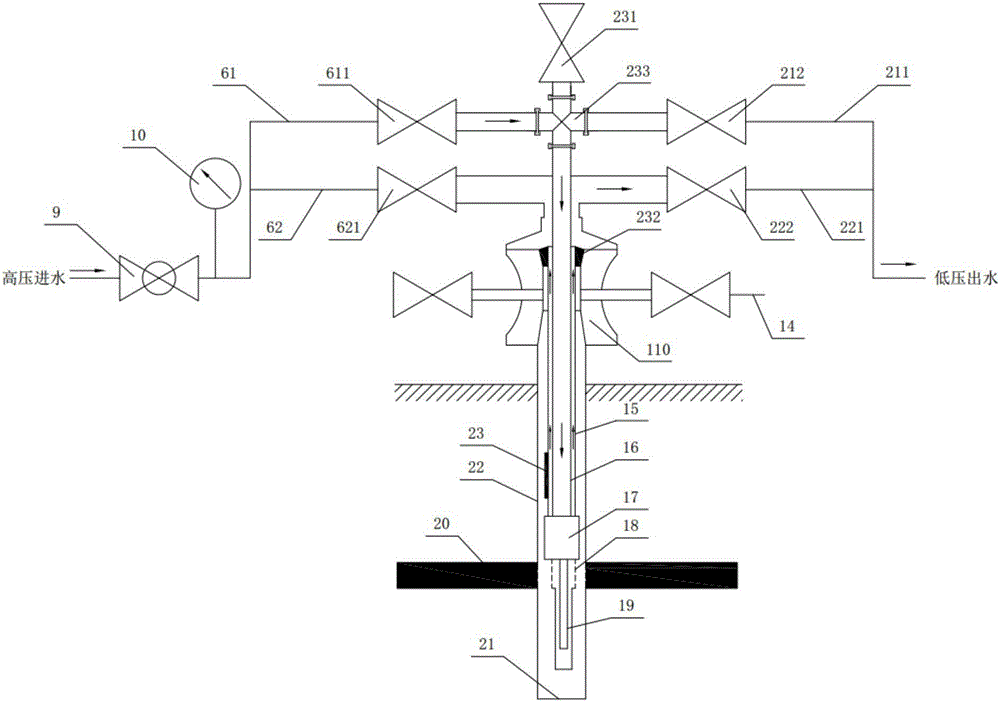

[0136] In another preferred embodiment of the present invention, the throwing-and-fishing type sand discharge and pulverized coal gas recovery device is similar to that of Embodiment 1, the only difference is that the mixed liquid pipe 15 is not set outside the power liquid pipe 16, but It is arranged side by side with the power fluid pipe 16.

[0137] The mixed liquid pipe 15 communicates with the outlet of the mixed liquid flow channel of the positive circulation reverse jet jet pump, and the power liquid pipe 16 communicates with the power liquid flow channel of the forward cycle reverse jet jet pump.

Embodiment 3

[0139] In another preferred embodiment of the present invention, the throwing-and-fishing type sand-discharging and pulverized-coal gas extraction device is similar to Embodiment 1, the only difference is that the high-pressure pipeline 6 is connected to a single well, and no branch pipeline is provided; the high-pressure pipeline Only the flowmeter 8 is installed on the 6, and the remote pressure gauge 5 is not installed. The automatic control device is directly connected with the flowmeter 8, and directly controls the power fluid flow to achieve the purpose of automatic control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com