A clutch flushing control system and flushing method thereof

A control system and clutch technology, applied in the field of control systems, can solve problems such as inability to carry pollutants out, failure to reach the flushing level, unqualified flushing, etc., to achieve the effect of improving cleaning quality and effect, ensuring effect, and improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

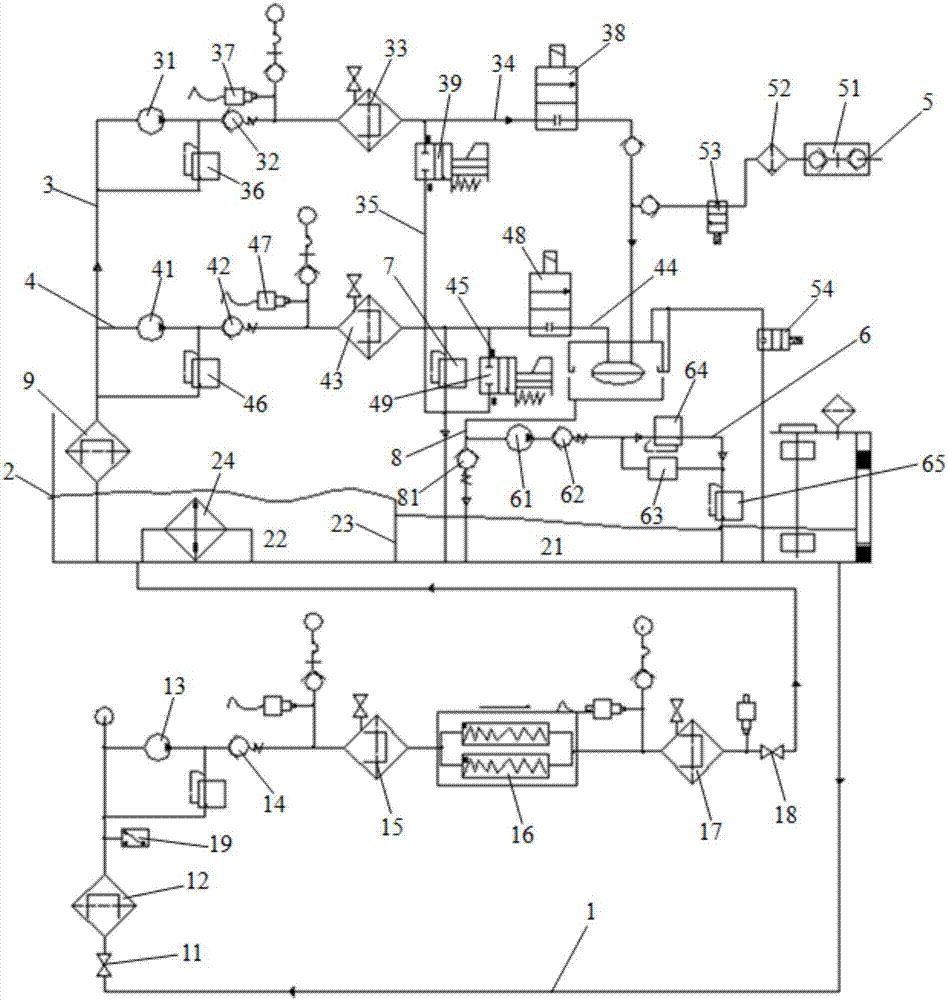

[0037] Please refer to figure 1 , the present embodiment is a clutch flushing control system, which includes an oil purification system 1, an oil tank 2 connected to the oil purification system 1 circuit, a clutch mid-way flushing oil circuit 3 connected to the oil tank 2, and a clutch mid-way flushing system 3 connected in parallel. Clutch inner angle flushing oil passage 4, clutch cleaning air passage 5 and online detection unit 6. The pipeline of the clutch middle road flushing oil passage 3 leads into from the middle part of the clutch. The pipeline of the clutch inner corner flushing oil circuit 4 leads into the two control ports of the clutch.

[0038] The oil tank 2 includes a dirty oil area 21 and a clean oil area 22 , and a partition 23 is arranged between the dirty oil area 21 and the clean oil area 22 . A heater 24 is arranged at the bottom of the clean oil zone 22 .

[0039] The clutch middle flushing oil circuit 3 includes the first oil pump 31 connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com