Assembly sealing ring of transitional section of aircraft engine and manufacturing and assembling method

An aircraft engine and transition section technology, which is applied to the sealing of the engine, engine components, mechanical equipment, etc., can solve the problems of increasing aircraft maintenance costs, affecting the execution of scientific research and flight tasks, and reducing the service life and maintenance cycle, so as to meet the overall requirements. Design requirements, the effect of improving density and connection strength, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

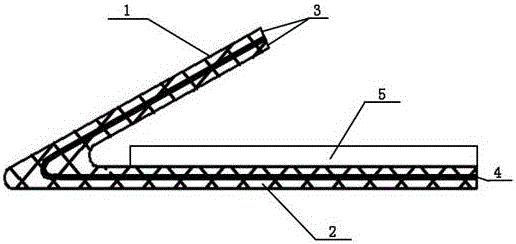

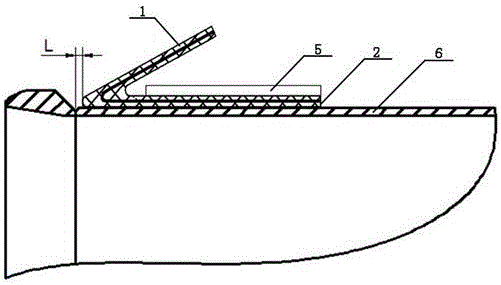

[0022] The structure, manufacture and assembly method of the aircraft engine transition section assembly sealing ring referred to in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] As shown in the figure, the assembly rubber sealing ring of the V-shaped cloth frame layer (4) is composed of the sealing working surface (1), the base (2) and the secondary fixing clamp (5). The layer (3) is saturated nitrile rubber, the cloth skeleton layer (4) is polyester fiber cloth, and the secondary fixing clamp (5) is a stainless steel belt that can be tightened by self-tapping.

[0024] Its production and assembly steps are as follows:

[0025] A. Preparation of the main compound rubber: use saturated nitrile rubber as the base rubber, use peroxide as the vulcanizing agent, supplemented by other rubber additives, and mix on the rubber mixer to prepare for use.

[0026] B. Preparation of cloth raw film: Heat the mixed rubber ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com