Material compacting device for similar material simulation test and using method

A similar material and simulation test technology, applied in the field of material compaction devices, can solve the problems of inability to ensure material compactness and flatness, high manufacturing costs and maintenance costs, and difficulty in satisfying rapid compaction of materials, and achieve good compaction effects , low maintenance cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention provides a material compaction device and method of use for similar material simulation tests. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples. illustrate.

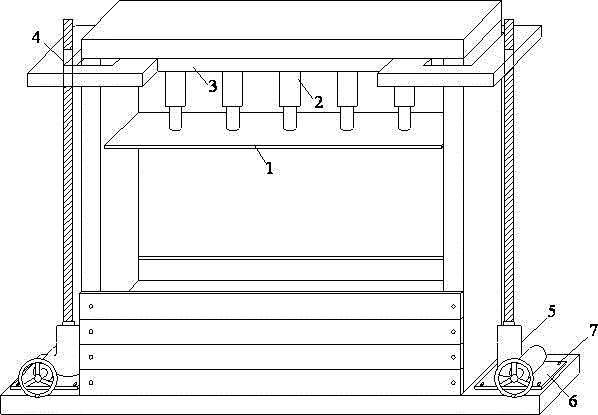

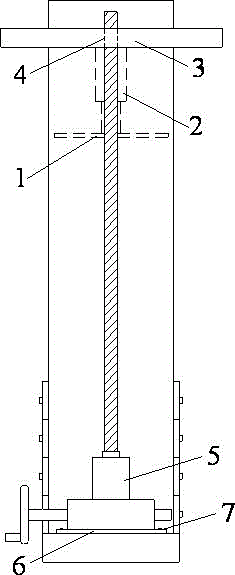

[0027] Such as Figure 1~Figure 2 As shown, a material compaction device for similar material simulation tests, including a pressure plate 1, a double-acting hydraulic jack 2, a double-acting hydraulic jack base 3, a hand-operated screw jack 5, and a hand-operated screw jack base6.

[0028] The pressure plate 1 is a rectangular steel plate. The length and width of the rectangular steel plate are slightly smaller than the length and width of the test material tank in the similar material simulation test. The rectangular steel plate is connected to the piston ends of all double-acting hydraulic jacks. s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com