Temperature control tunable optical fiber filter based on micro-nano optical fibers and manufacturing method

A technology of optical fiber filter and micro-nano optical fiber, which is applied in the field of optical fiber technology and optical filtering, and can solve problems such as difficult optical processing, hysteresis, and complex system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

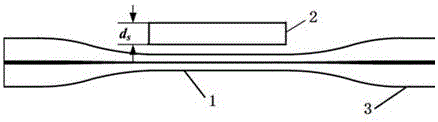

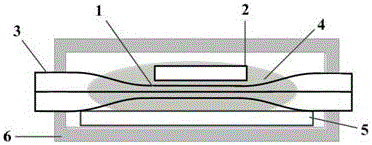

[0026] Such as figure 1 and figure 2 As shown, a temperature-controlled tunable optical fiber filter based on micro-nano fiber, at least includes: micro-nano fiber 1 and flat optical waveguide 2, the micro-nano fiber 1 is made of single-mode fiber 3 through fusion tapering process The diameters at both ends are constant, and the middle is a micro-nano-level waist region structure. The length of the thin waist region is at least greater than or equal to the length of the flat optical waveguide 2. The micro-nano optical fiber 1 and the flat optical waveguide 2 are pasted together by optical glue 4. waveguide coupling structure.

[0027] The micro-nano optical fiber 1 and the flat optical waveguide 2 are pasted on the glass substrate 5 through optical glue 4 .

[0028] The micro-nano optical fiber 1 and the flat optical waveguide 2 are glued together by optical glue 4, and the optical glue 4 completely wraps the thin waist region of the micro-nano optical fiber.

[0029] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com