Modeling method for serial double-wire submerged arc welding numerical simulation heat source model

A technology of heat source model and numerical simulation, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the shape of the fusion line cannot be effectively controlled, and achieve the effect of strong controllability and simple construction form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

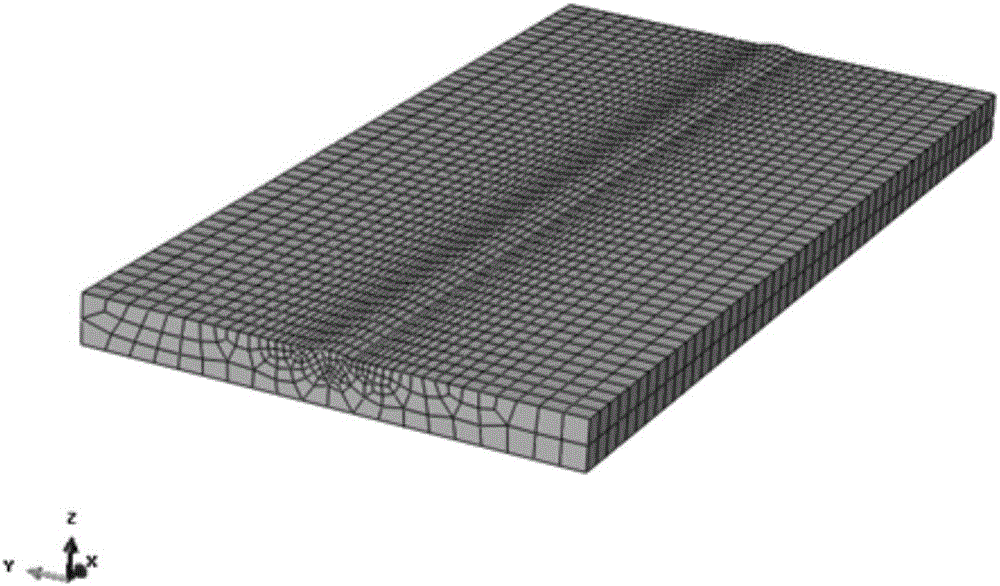

[0027] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

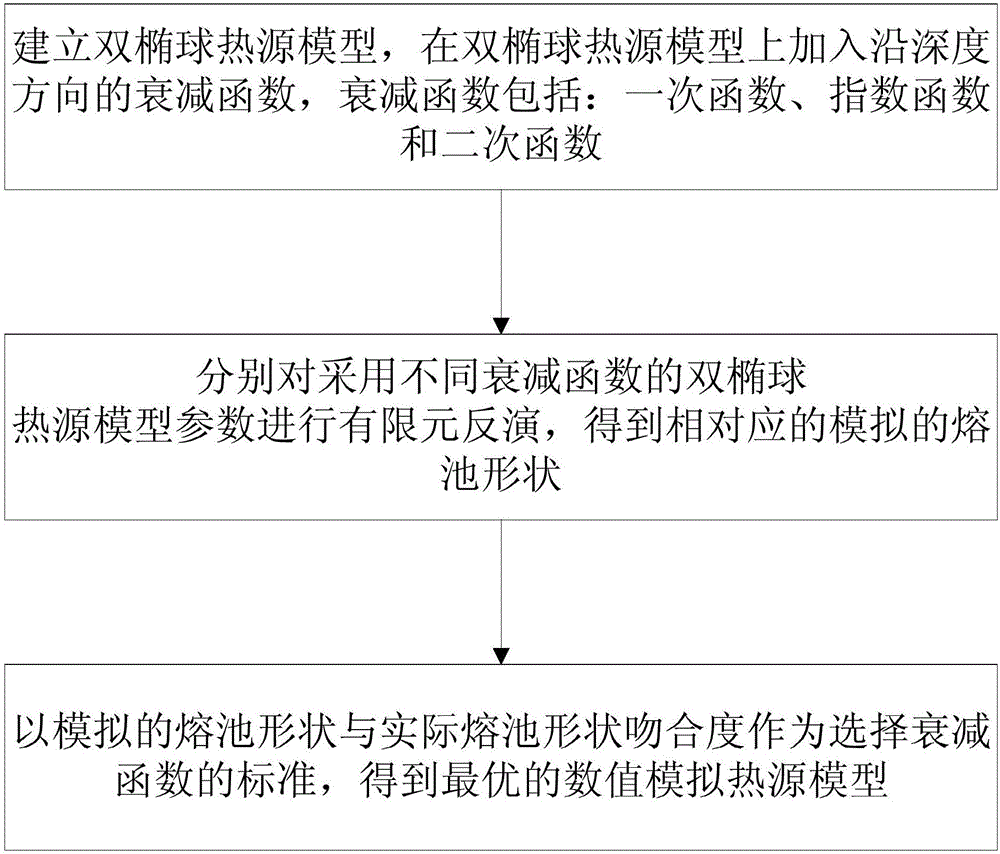

[0028] Such as figure 1 As shown, a kind of modeling method of tandem twin-wire submerged arc welding numerical simulation heat source model of the present invention comprises the following steps:

[0029] Step 1: Add the attenuation function along the depth direction to the double ellipsoid heat source model, and establish a double filament model with two such double ellipsoid heat source models.

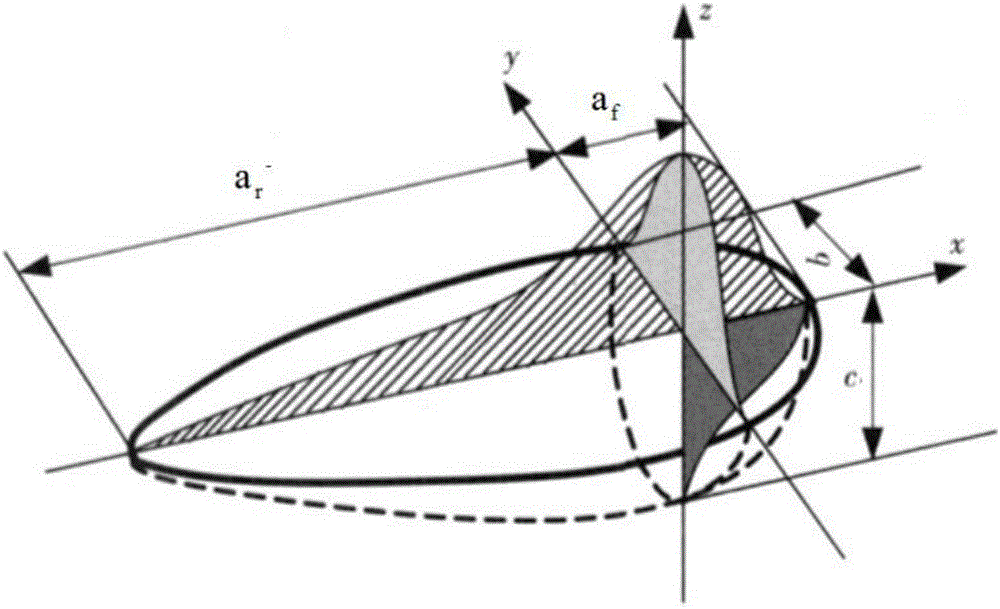

[0030] In the prior art, the double ellipsoidal heat source model such as figure 2 As shown, the double ellipsoidal heat source model sets the first half of the welding pool as a 1 / 4 ellipsoid, and the second half as another 1 / 4 ellipsoid, and the heat flux is normally distributed in a Gaussian fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com