Sealed high-voltage direct-current relay

A high-voltage DC, relay technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of thermal expansion and contraction of sealant, scorched and yellowing of sealant, leakage of inert gas, etc., to avoid damage, The effect of improving strength, ensuring performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below according to the accompanying drawings and specific embodiments.

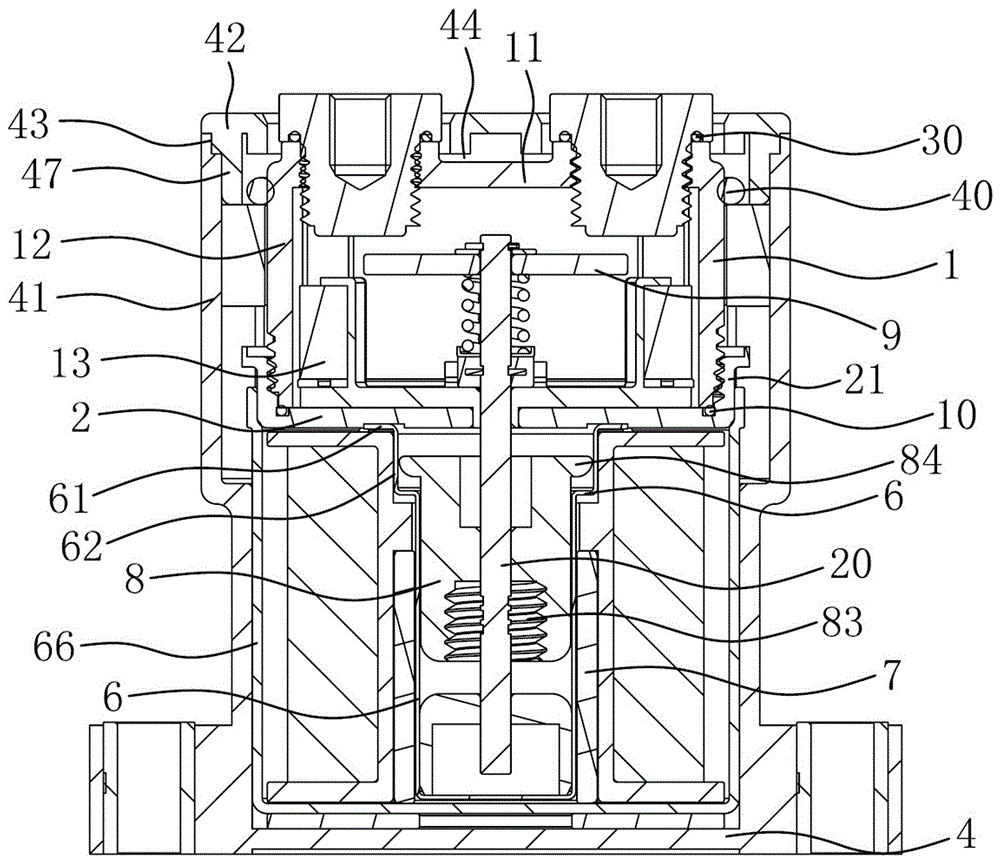

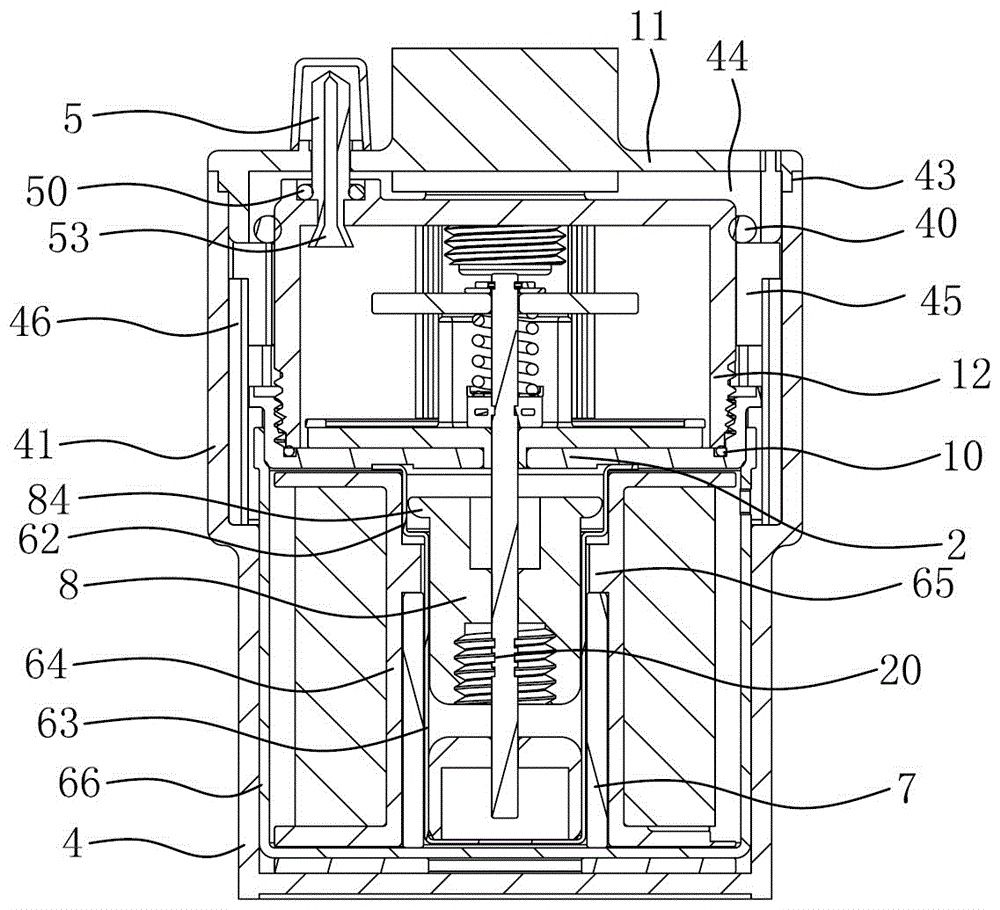

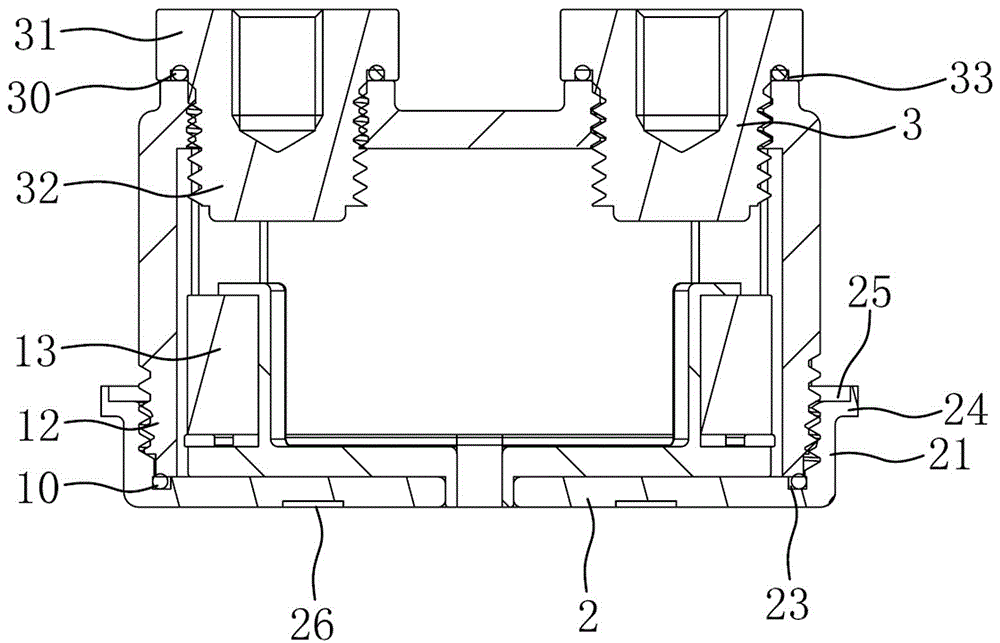

[0034] Depend on figure 1 , figure 2 , image 3 As shown, a sealed high-voltage DC relay of the present invention includes an insulating cover 1 and a yoke 2. The yoke 2 extends upward to form a cylindrical yoke fixing part 21. The insulating cover 1 includes a top 11, and the top 11 is directed toward There is a cylindrical insulating cover fixing part 12 extending downward. The top 11 cooperates with the insulating cover fixing part 12 to form an inverted cup-shaped structure. point chamber, the lower end of the insulating cover fixing part 12 and the yoke fixing part 21 are screwed together, the lower side of the lower end of the insulating cover fixing part 12 is provided with a first sealing ring 10, the lower end of the insulating cover fixing part 12 and the yoke fixing part 21 The thread mating parts are filled with sealing glue.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com