Appearance inspection method and inspection system of inkless wafer

A visual inspection, wafer technology, applied in the direction of electrical components, circuits, semiconductor/solid-state device testing/measurement, etc., can solve the problems of low production efficiency, unevenness, ink dot thickness, etc., to improve yield, data Precise, the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

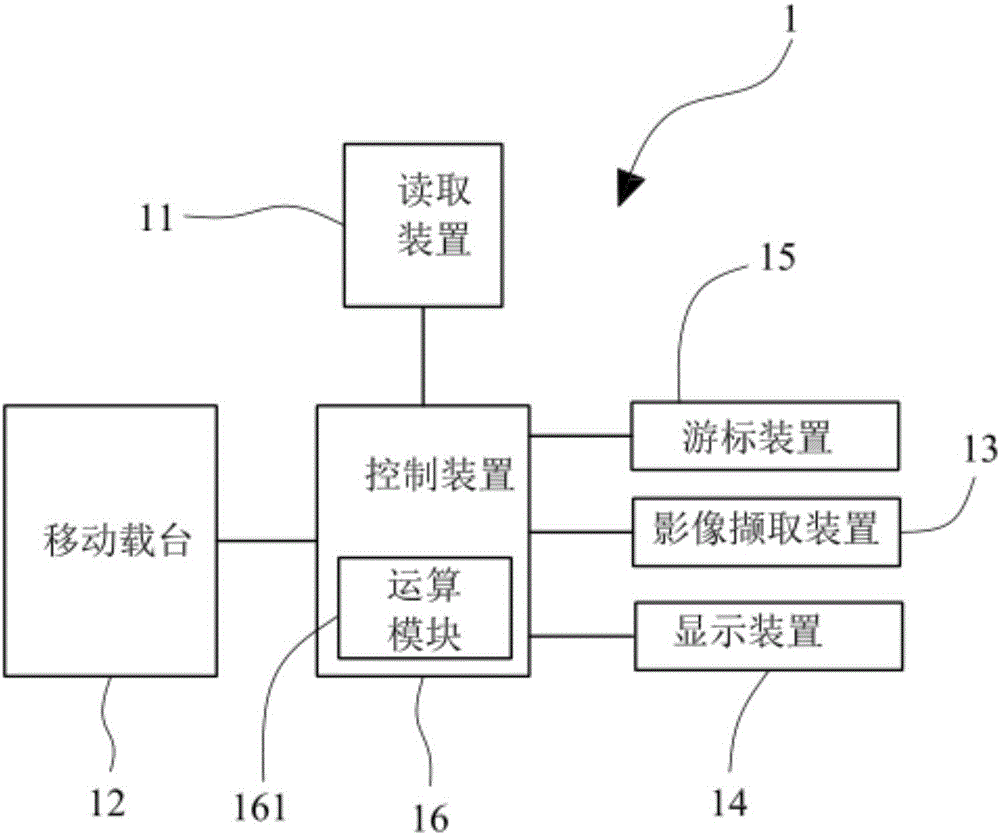

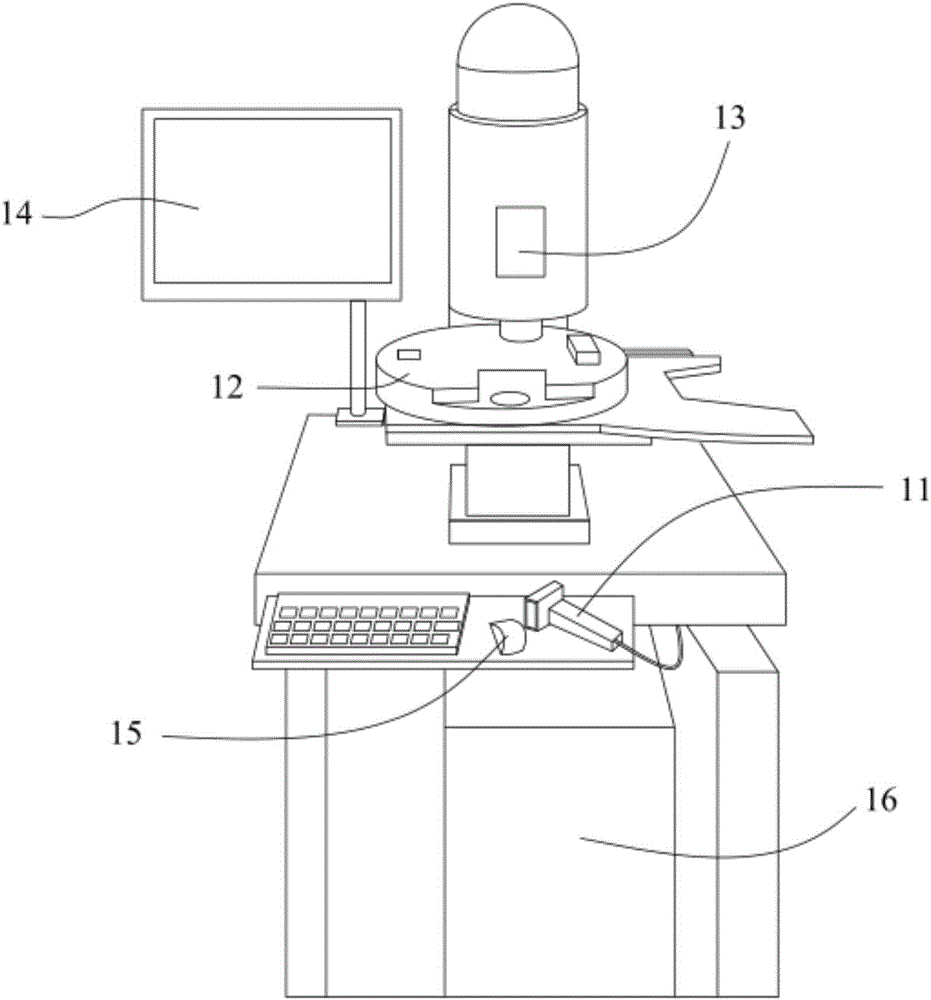

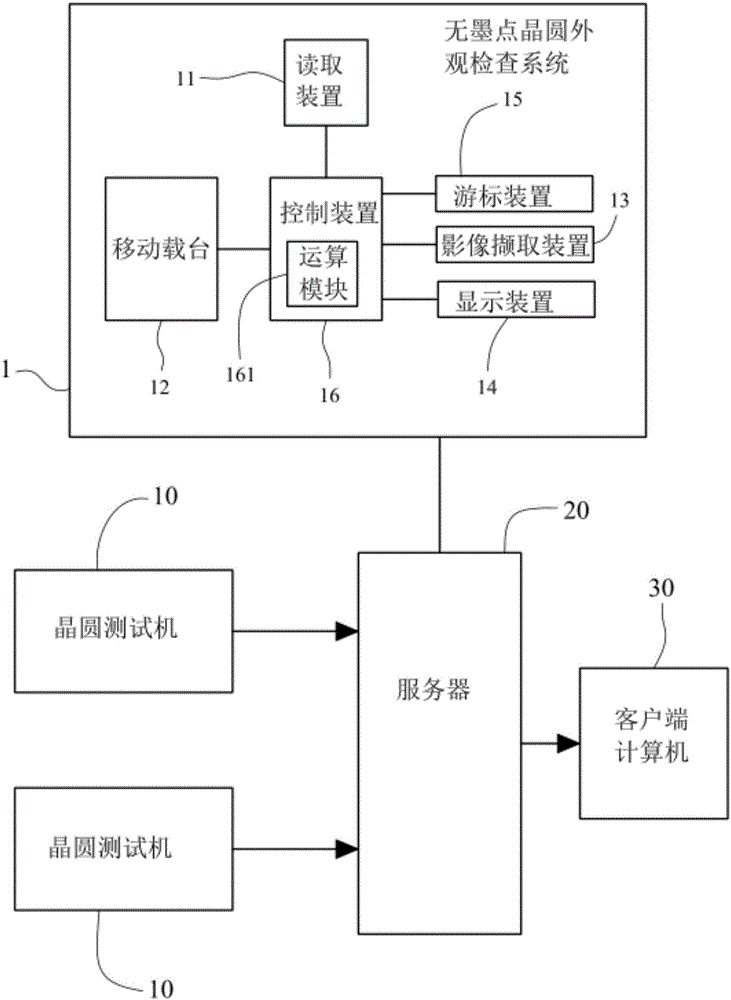

[0034] Such as Figure 1A and Figure 1B As shown, it is a system architecture diagram and a schematic appearance diagram of the ink-dot-free wafer appearance inspection system of the present invention. The wafer appearance inspection system 1 without ink dots of the present invention includes: a reading device 11 , a moving stage 12 , an image capture device 13 , a display device 14 , a cursor device 15 and a control device 16 connected to the aforementioned devices.

[0035] The mobile stage 12 can be used to place a wafer to be inspected, and can carry the wafer for horizontal adjustment. The reading device 11 is used to read the serial number on the wafer and the wafer map corresponding to the serial number, and then the data of the wafer map is transmitted to the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com