Shaft hoisting container charging device

A charging device and wellbore technology, applied in the direction of circuit devices, battery circuit devices, collectors, etc., can solve the problems of small battery capacity, restrictions on automatic loading, difficult maintenance, etc., to prevent electrification, prevent creepage, and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

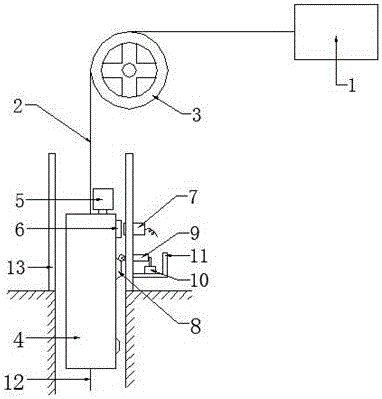

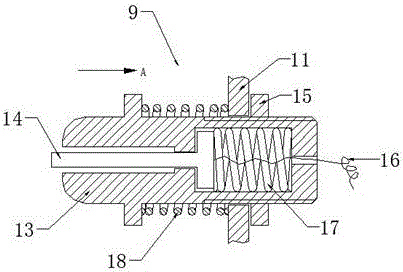

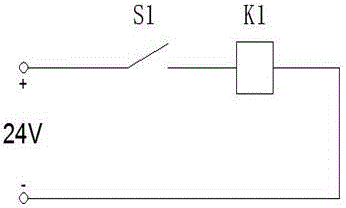

[0015] A shaft hoist container charging device, including a motor 1, a traction rope 2, a drum 3, a shaft hoist container 4, a lithium battery 5, a magnetic source 6, a position sensor 7, a buffer contact (8), a contact charger 9, and an explosion-proof power supply Box 10, fixed bracket 11 and balance tail rope 12, the traction rope 2 bypasses the drum 3, one end is connected with the motor 1, and the other end is connected with the wellbore lifting container 4, and the motor 1 lifts the wellbore container 4 through the traction rope 2 , the lithium battery 5 is installed on the top of the shaft lifting container 4, the magnetic source 6 is installed on the outer wall of the shaft lifting container 4, and is close to the top, the position sensor 7 is installed on the inner wall of the shaft, and the position sensor 7 Aligned on a line with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com