Efficient isolation type DC full-bridge conversion circuit

A full-bridge conversion and full-bridge circuit technology, which is applied in the field of high-efficiency isolated DC full-bridge conversion circuits, can solve the problems of large current, large on-state loss of the main circuit, and large additional on-state loss of the switching device of the lagging bridge arm. Achieve the effect of current reduction and additional on-state loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

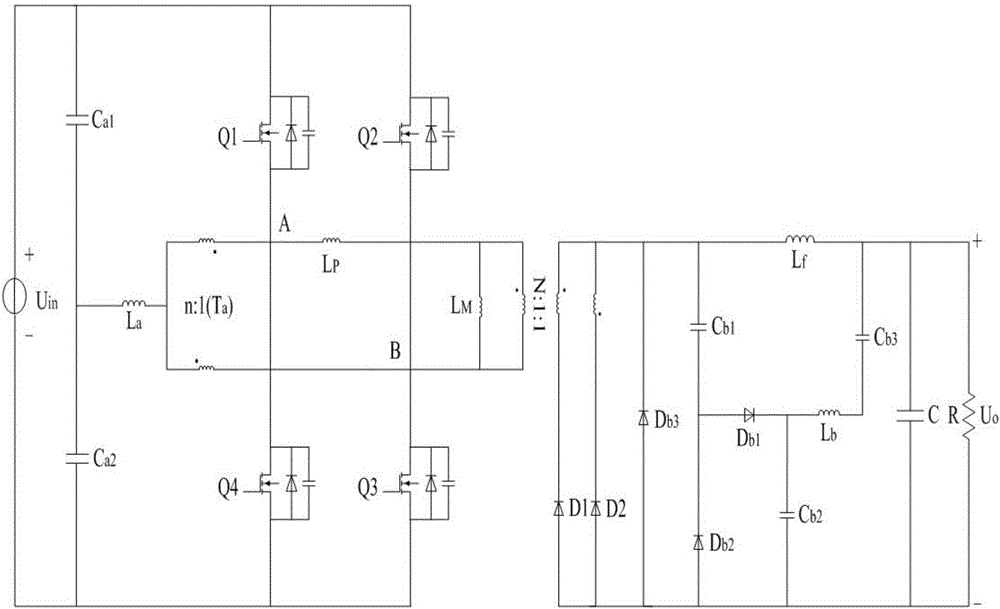

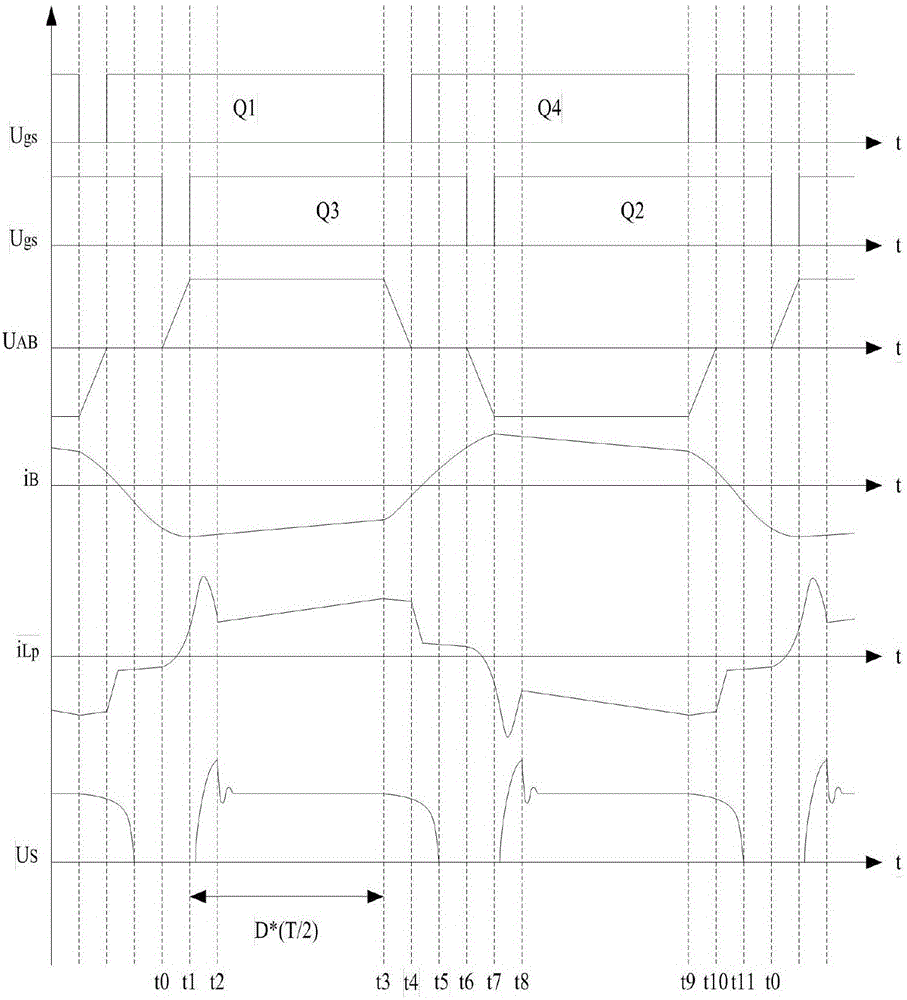

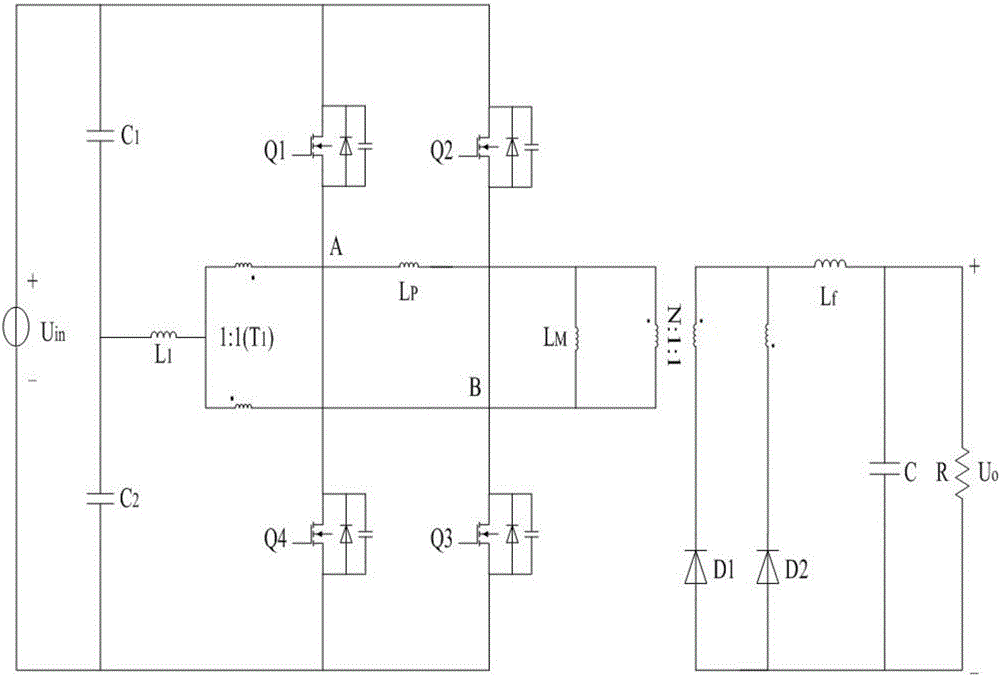

[0027] A high-efficiency isolated DC full-bridge conversion circuit is a comparison of existing isolated DC full-bridge conversion circuits (such as image 3 Shown) is improved. The high-efficiency isolated DC full-bridge conversion circuit is composed of six parts: auxiliary current source, full-bridge circuit, high-frequency transformer, synchronous rectifier circuit, filter circuit and reset capacitor circuit. It is the same as the existing isolated DC full-bridge conversion circuit ( image 3 ) Has the following differences:

[0028] 1. C in the existing conversion circuit 1 And C 2 It is a voltage equalizing capacitor, the midpoint voltage of the two remains unchanged, and the magnitude is the input voltage U in Half of it. Although the conversion circuit of the present invention still connects the two capacitors in series in the auxiliary cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com