Melilite structure crystal zero/ near-zero frequency temperature coefficient cut and processing method and application thereof

A frequency temperature coefficient, feldspar-type technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of narrow application temperature range and low application temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

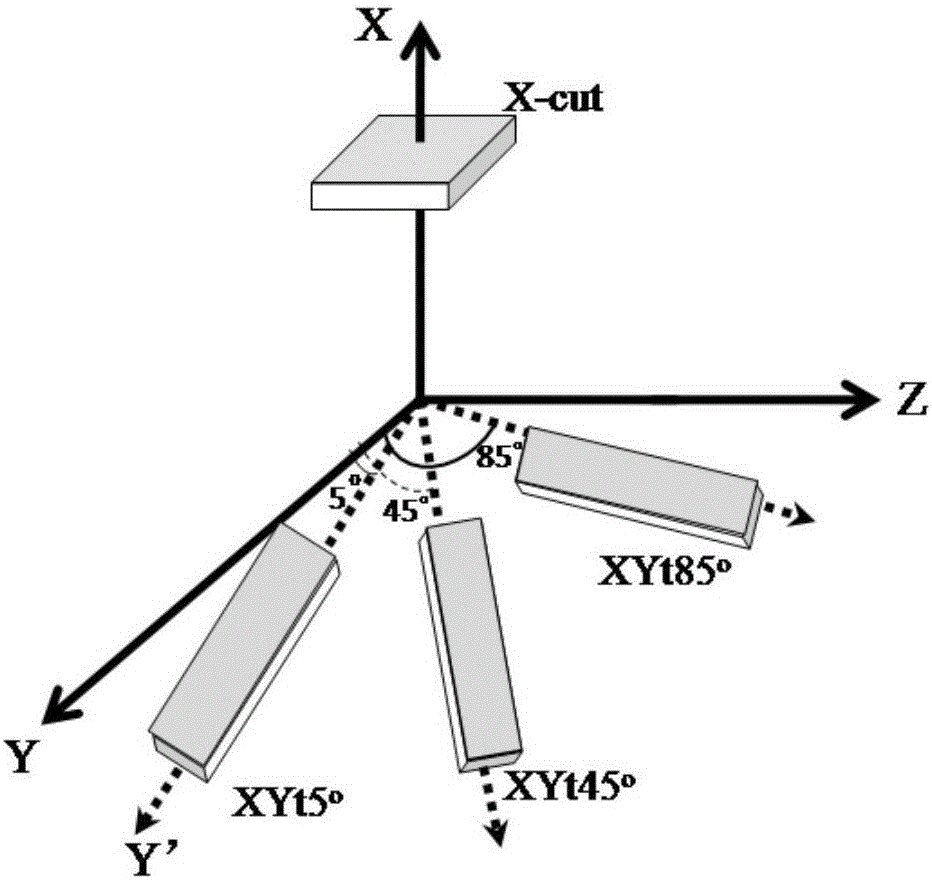

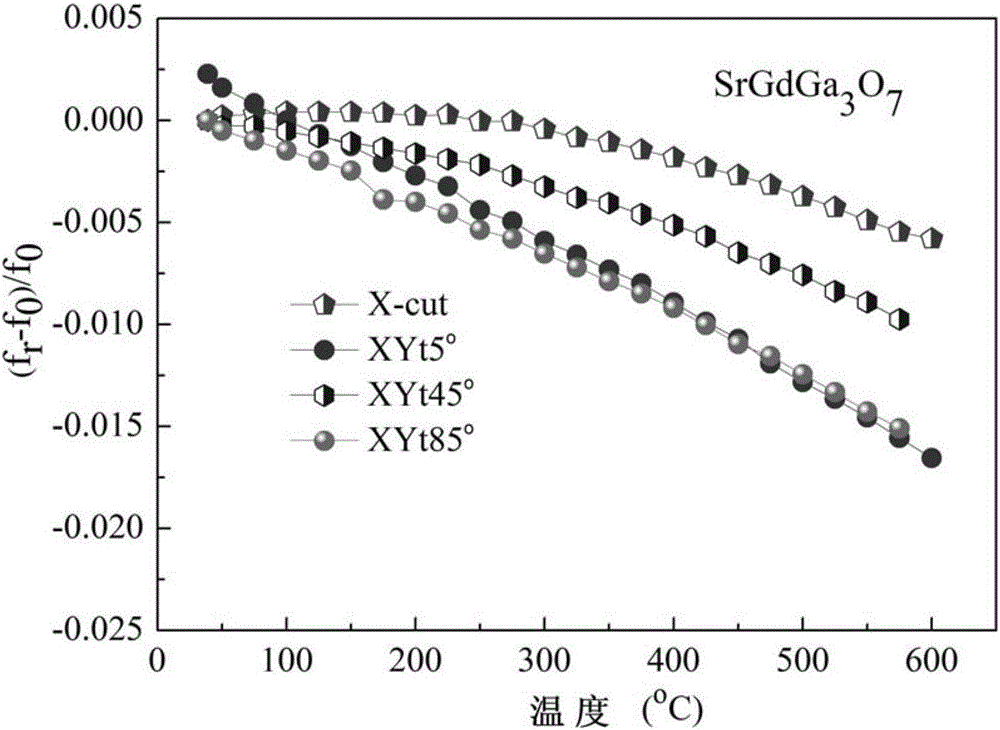

[0096] Embodiment 1: Referring to the above sample processing steps, process SrGdGa 3 o 7 Crystal sample size is 1.5×8×8mm 3 (X×Y×Z) X-cut, and the size is 1.6×3.5×12mm 3 (X×Z×Y) XYt5°, XYt45°, XYt85° strip samples, test their frequency temperature characteristics in the temperature range of 20-600°C, such as image 3 As shown, the study found that the frequency temperature coefficients of X-cut, XYt5°, XYt45°, and XYt85° are -10ppm / °C, -32ppm / °C, -17ppm / °C and -25ppm / °C respectively. The schematic diagram of the zero / near zero frequency temperature compensation cut shape of the sample in the coordinate system is as follows figure 1 shown.

Embodiment 2

[0097] Embodiment 2: Referring to the above-mentioned sample processing steps, process BaLaGa 3 o 7 Crystal ZXt45° strip sample, the size is 1.5×3.6×11.8mm 3 (Z×Y×X), excite length stretching vibration.

[0098] Processing SrLaGa 3 o 7 Crystal XYt45° strip sample, the size is 1.6×3.8×12.0mm 3 (X×Z×Y), excite length stretching vibration.

[0099] Processing SrNdGa 3 o 7 X-cut sample of crystal, sample size is 1.5×7.8×7.8mm 3 (X×Y×Z), excited plane shear vibration.

[0100] In the temperature range of 20-600 °C, the frequency temperature characteristics of the above three cutting types are tested, such as Figure 4 As shown, the study found that BaLaGa 3 o 7 Crystal ZXt45°cut type, SrLaGa 3 o 7 Crystal XYt45°cut type, SrNdGa 3 o 7 The frequency temperature coefficients of X-cut cut crystals are -53, -43, -52ppm / ℃ respectively.

Embodiment 3

[0101] Embodiment 3: with reference to the above-mentioned sample processing steps, process Ca 2 Ga 2 SiO 7 Crystal XYt5° and ZXt45° strip samples, sample size is 1.6×3.5×12mm 3 (X×Z×Y), excite the transverse length stretching vibration.

[0102] Processing Ca 2 MgSi 2 o 7Crystal XYt5° and XYt85°, sample size is 1.4×3.6×11.8mm 3 (X×Z×Y), excite the transverse length stretching vibration.

[0103] Test frequency temperature characteristics in the temperature range of 20-600°C, such as Figure 5 As shown, the study found that Ca 2 Ga 2 SiO 7 Crystal XYt5° cut shape, Ca 2 Ga 2 SiO 7 Crystal ZXt45° cut shape, Ca 2 MgSi 2 o 7 Crystal XYt5° cut shape, Ca 2 MgSi 2 o 7 The frequency temperature coefficients of the crystal XYt85°cut are -21, -43, -25, -24ppm / ℃ respectively. It should be pointed out that, Figure 5 Medium Ca 2 MgSi 2 o 7 The relative frequency of the crystal has an abnormal peak at around 75°C with temperature, which is related to the commensurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com