Si, Mg and Zr micro-alloyed AlCuMn heat-resistant aluminum alloy and heat treatment process

A micro-alloying and alloying technology, which is applied in the field of alloy materials, can solve the problem that the heat resistance of alloys has little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Using graphite crucible smelting and iron mold casting to prepare alloy ingots, using raw materials as high-purity aluminum, pure magnesium, Al-50%Cu, Al-10%Mn, Al-24%Si, Al-10%Zr Intermediate alloy. First put high-purity aluminum into a graphite crucible, heat and melt it in a high-temperature melting furnace at 800±5℃, and then add Al-50%Cu, Al-10%Mn, Al-24%Si, Al-10%Zr intermediate Alloy, when adding pure Mg, it needs to be wrapped with aluminum foil to reduce the burning loss of Mg, and then fully stirred. After it is fully melted, C 2 Cl 6 Degassing, stirring, heat preservation and standing, and then iron mold casting to obtain an ingot. Four kinds of alloy materials with different compositions were prepared, and the actual composition of the alloy was obtained by XRF test, as shown in Table 1:

[0037] Table 1: Composition table of alloys measured by XRF

[0038]

Embodiment 2

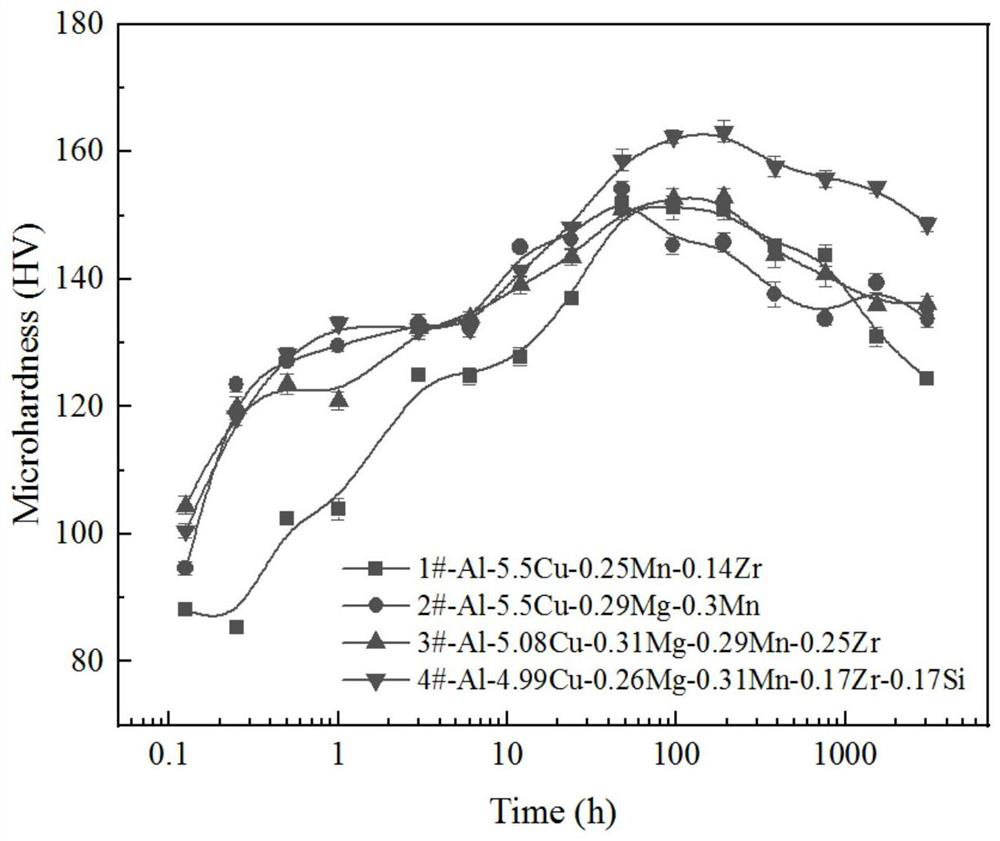

[0039] Embodiment 2: After the 1#, 2#, 3#, 4# as-cast alloys in Example 1 are heated from room temperature for 6h to 540°C, after solution treatment for 7h, water quenched to room temperature in 10s, at 150 °C. After the isothermal aging at ℃ reaches the peak value, it is then aged at 150 ℃ for a long time to obtain the aging hardness curves of the four alloys at this temperature, such as figure 1 shown. As can be seen from the figure, at this temperature, comparing the 1# and 3# alloys, after 768h, the hardness value of the 1# alloy began to decrease rapidly, while the 3# alloy remained stable. Comparing the 3# and 4# alloys, the hardness value of the 4# alloy has been significantly higher than that of the 3# alloy, indicating that the composite addition of Si and Mg can significantly improve the aging hardness and thermal stability of the alloy at lower temperatures. Comparing the 2# and 3# alloys, it can be seen that Zr does not work at lower temperatures.

Embodiment 3

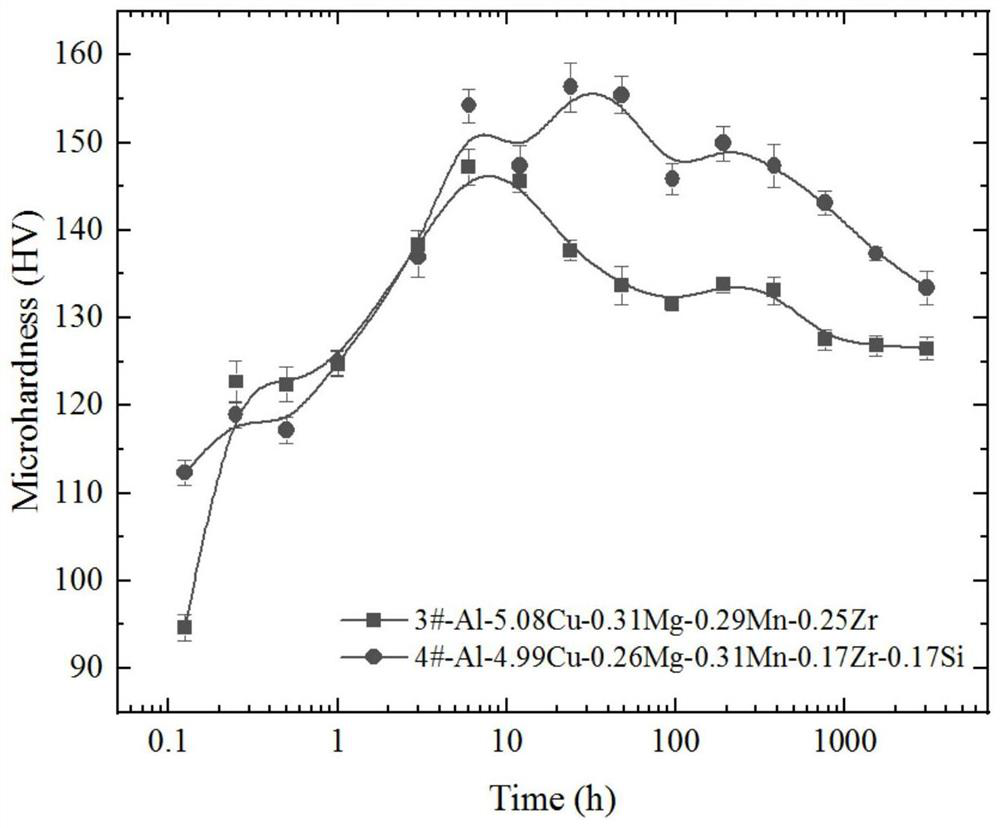

[0040] Example 3: The 3# and 4# as-cast alloys in Example 1 were heated from room temperature for 6h to 540°C, and after solution treatment for 7h, water quenched to room temperature in 10s, and after isothermal aging at 175°C reached a peak value. , and then aged at 175 °C for a long time to obtain the aging hardness curves of the two alloys at this temperature, such as figure 2 shown. It can be seen from the figure that the hardness value of 4# alloy is always significantly higher than that of 3# alloy in the long-term aging process, indicating that the aging strengthening effect of Si is also very significant at this temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com