Electrolyte for low-temperature lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in electrolytes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of increasing negative lithium ion de-intercalation resistance, decreasing conductivity, and increasing electrolyte viscosity. , to achieve the effect of broadening the application temperature range and improving low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

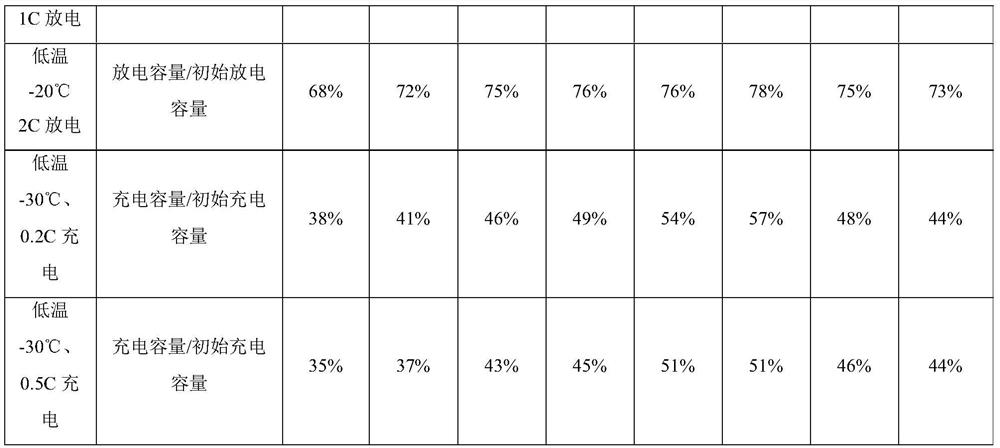

Examples

Embodiment 1

[0027] The electrolyte in this embodiment consists of a solvent, an additive and a lithium salt.

[0028] Lithium salt made from lithium hexafluorophosphate LiPF 6 (14%wt), lithium bisfluorosulfonimide LiFSI (1%wt). The mixed solvent consists of ethylene carbonate EC (25%wt), ethylmethyl carbonate EMC (30%wt), ethyl propionate EP (20%wt). The additive consisted of vinylene carbonate VC (5%wt), fluoroethylene carbonate FEC (5%wt).

[0029] Randomly select 6 lithium-ion batteries that have not been filled with liquid, and respectively inject the electrolyte solution provided in this embodiment in a low dew point drying room. The production of a complete lithium-ion battery is completed through standing, chemical formation, pretreatment, pumping, (secondary liquid injection), sealing, volume separation, and aging.

[0030] Lithium-ion batteries are organically assembled from positive pole pieces, separators, and negative pole pieces, and are sealed in the casing after being we...

Embodiment 2

[0032] The electrolyte in this embodiment consists of a solvent, an additive and a lithium salt.

[0033] Lithium salt made from lithium hexafluorophosphate LiPF 6 (13%wt), lithium bisfluorosulfonimide LiFSI (2%wt). The mixed solvent consists of dimethyl carbonate (10%wt), ethylene carbonate EC (20%wt), ethylmethyl carbonate EMC (25%wt), ethyl propionate EP (20%wt). The additive consisted of vinylene carbonate VC (5%wt), fluoroethylene carbonate FEC (5%wt).

[0034] Randomly select 6 lithium-ion batteries that have not been filled with liquid, and respectively inject the electrolyte solution provided in this embodiment in a low dew point drying room. The production of a complete lithium-ion battery is completed through standing, chemical formation, pretreatment, pumping, (secondary liquid injection), sealing, volume separation, and aging.

[0035] Lithium-ion batteries are organically assembled from positive pole pieces, separators, and negative pole pieces, and are sealed ...

Embodiment 3

[0037] The electrolyte in this embodiment consists of a solvent, an additive and a lithium salt.

[0038]Lithium salt made from lithium hexafluorophosphate LiPF 6 (12%wt), lithium bisfluorosulfonimide LiFSI (2%wt), lithium difluorophosphate LiPO 2 f 2 Composition (1% wt). The mixed solvent consists of dimethyl carbonate (10%wt), ethylene carbonate EC (20%wt), ethylmethyl carbonate EMC (25%wt), ethyl propionate EP (20%wt). The additive consisted of vinylene carbonate VC (5%wt), fluoroethylene carbonate FEC (5%wt).

[0039] Randomly select 6 lithium-ion batteries that have not been filled with liquid, and respectively inject the electrolyte solution provided in this embodiment in a low dew point drying room. The production of a complete lithium-ion battery is completed through standing, chemical formation, pretreatment, pumping, (secondary liquid injection), sealing, volume separation, and aging.

[0040] Lithium-ion batteries are organically assembled from positive pole pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com