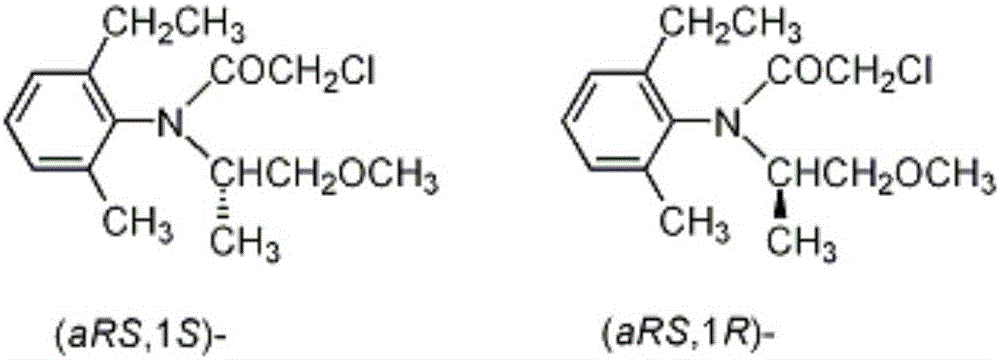

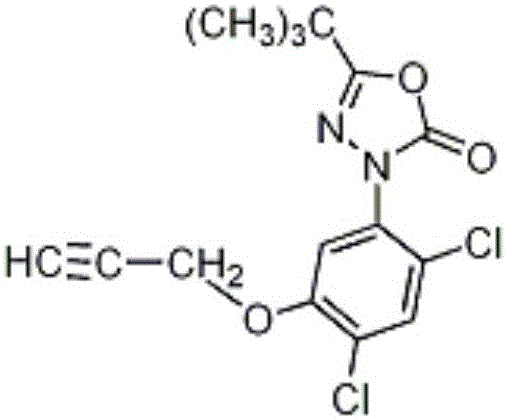

Micro-capsule suspension-suspension agent of s-metolachlor and oxadiargyl and preparation method thereof

A technology of refined metolachlor and propargyl oxadiazone, applied in the field of pesticides, can solve the problems of farmland weed population change and community succession acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

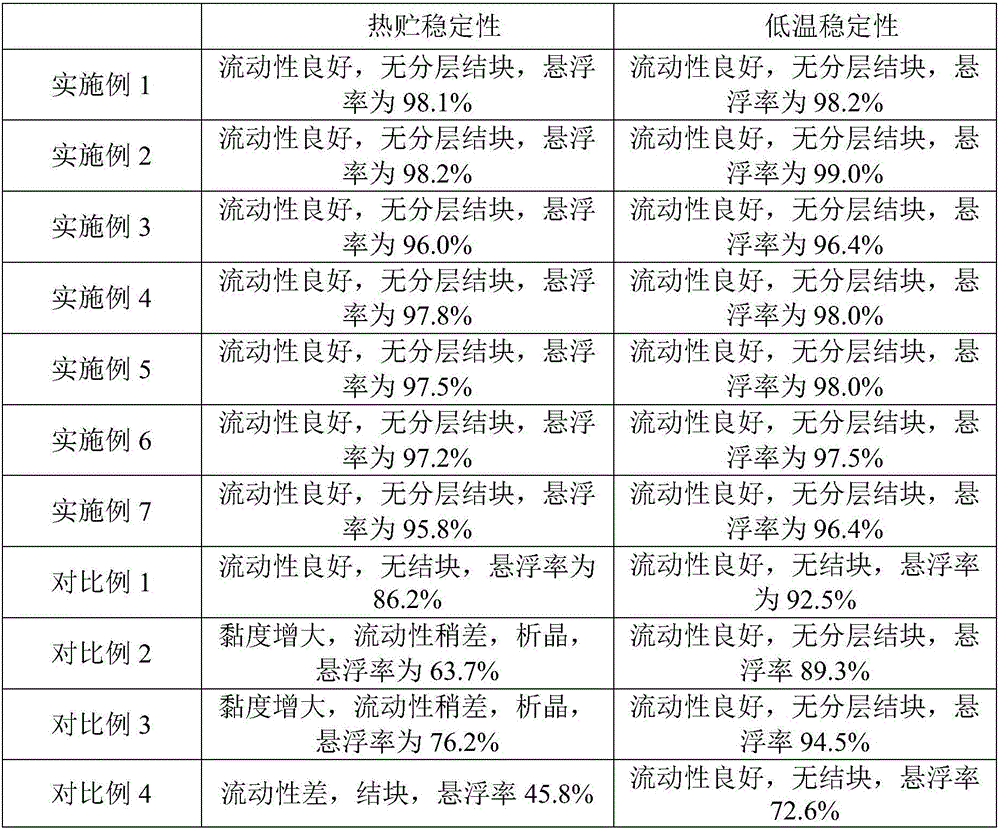

Examples

preparation example Construction

[0010] The invention discloses a preparation method of a microcapsule suspension-suspension agent of refined metolachlor and propargyl oxadiazone, wherein the preparation method may include the following steps: (1) adding the oil phase material into the water phase Stir in the material to form an O / W emulsion, the weight ratio of the oil phase material to the water phase material can be 1: (0.5-2); the oil phase material can contain refined metolachlor, oil-soluble Shell material and solvent; the water phase material may contain water; (2) adding a water-soluble shell material to the O / W emulsion and mixing uniformly to obtain a fine metolachlor microcapsule suspension ; The weight ratio of the O / W emulsion and the water-soluble capsule shell material can be 1: (0.001-1.5); (3) add propargyl oxadiazone to the fine metolachlor microcapsule suspending agent to suspend agent, obtain the fine metolachlor and propargyl oxadiazone microcapsule suspension-suspension concentrate, the ...

Embodiment 128

[0032]Example 1 28% pure metolachlor propargyl oxadiazone microcapsule suspension-suspension

[0033] (1) Preparation of 35% refined metolachlor microcapsule suspension

[0034] Dissolve 36.5 g of pure metolachlor with a purity of 96% in 30 g of 200# solvent oil, add 2 g of aliphatic polyisocyanate and 3 g of sorbitan polyoxyethylene ether, and stir evenly to obtain an oil phase material; Sodium sulfonate, 0.2g of silicone antifoaming agent was dissolved in 24.8g of water to obtain a water phase material; then the oil phase material was added to the water phase material, and sheared for 1 minute at 10,000 rpm to form an O / W emulsion; 0.5 g of ethylenediamine was added dropwise to the emulsion, and the temperature was raised to 50° C. for 2 hours of heat preservation reaction to obtain 100 g of 35% refined metolachlor microcapsule suspension.

[0035] (2) Preparation of 25% propargyl oxadiazone suspension concentrate

[0036] 26g of propargyl oxadiazone with a purity of 96%, ...

Embodiment 228

[0039] Example 2 Preparation of 28% refined metolachlor-propargyl oxadiazone microcapsule suspension-suspension

[0040] (1) Preparation of 35% refined metolachlor microcapsule suspension

[0041] Dissolve 36.5 g of pure metolachlor with a purity of 96% in 30 g of 200# solvent oil, add 2.5 g of aliphatic polyisocyanate and 3 g of sorbitan polyoxyethylene ether, and stir evenly to obtain an oil phase material; Sodium lignosulfonate, 0.2g of silicone defoamer dissolved in 24.3g of water to obtain the water phase material; then the oil phase material was added to the water phase material, sheared at 12000 rpm for 1 minute to form an O / W emulsion Add 0.5 g of ethylenediamine dropwise to the emulsion, raise the temperature to 50° C. and keep it warm for 2.5 hours to obtain 100 g of 35% refined metolachlor microcapsule suspension.

[0042] (2) Preparation of 25% propargyl oxadiazone suspension concentrate

[0043] With embodiment 1.

[0044] (3) Preparation of 28% refined metolac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com