Quick processing method of broken black tea

A processing method and technology of crushed red tea, which is applied in the field of fast processing of crushed red tea, can solve the problems of weak tea soup, high loss, and dark leaf bottom of red crushed tea, so as to shorten the processing time, reduce the loss of nutritional components, and reduce the The effect of kneading and cutting times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

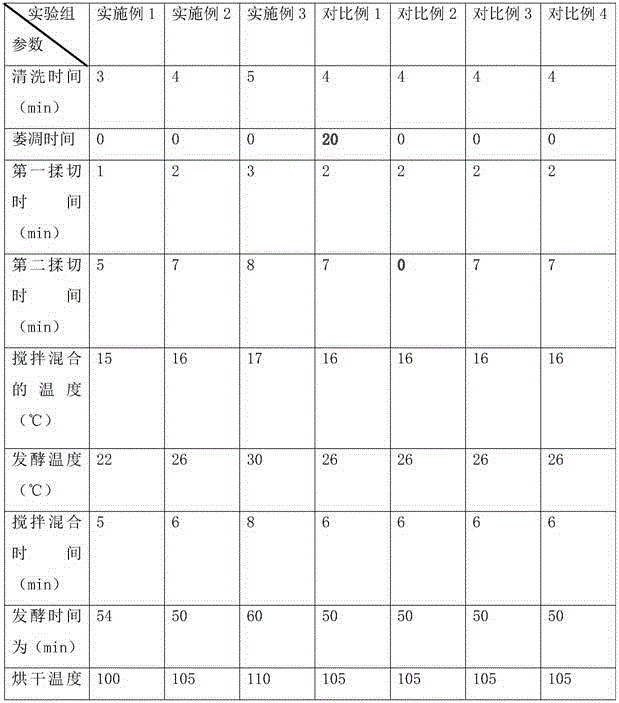

[0021] Embodiment 1: a kind of fast black broken tea processing method comprises the following steps:

[0022] S1: Fresh leaf treatment: pick fresh black tea leaves, and wash the black tea leaves for 3 minutes;

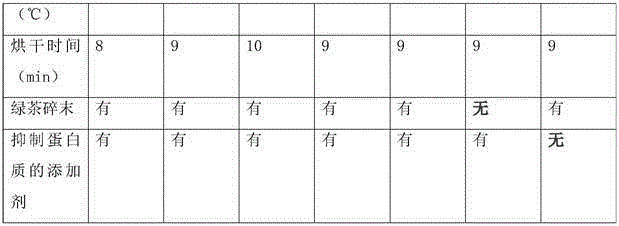

[0023] S2: Kneading and cutting: Knead and cut the cleaned black tea leaves. When the kneading and cutting time is 1 min, add green tea powder for the first time, and stir the black tea leaves and green tea powder to form the first mixture; Knead and cut the mixture for 5 minutes, add green tea powder for the second time, stir the black tea leaves and green tea powder to form the second mixture; the mass ratio of the green tea powder added for the first time to the green tea powder added for the second time is 2 :1, the mass ratio of the green tea powder added for the first time and the green tea powder sum added for the second time to the black tea leaves is 1:8;

[0024] S3: Addition: Add protein-inhibiting additives to the second mixture, stir and mix the second m...

Embodiment 2

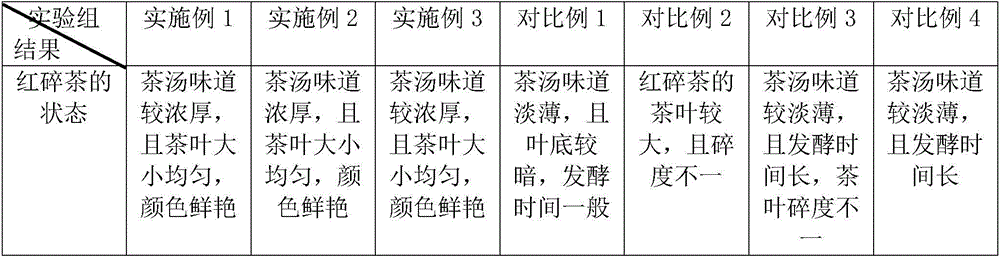

[0035] Example 2 Compared with Comparative Example 1, the tea soup of the red crushed tea in Comparative Example 1 has a weak taste, and the bottom of the leaves is darker, and the fermentation time is average, mainly because a large amount of protein is produced due to the setting of the withering link, and the protein and tea are more Phenols, catechins, etc. react to form precipitates, so that the tea soup tastes light and the bottom of the leaves is darker, but in this process, green tea powder is added to increase the concentration of tea polyphenols and catechins, so that the fermentation time generally.

[0036] Compared with Comparative Example 2 in Example 2, the black crushed tea made in Comparative Example 2 has larger tea leaves and different degrees of crushing, mainly because the black tea leaves have not been kneaded and cut for many times, and the kneading and cutting effect is general.

[0037] Example 2 Compared with Comparative Example 3, the taste of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com