Strip tea and processing method thereof

A processing method and strip tea technology, which is applied in the field of strip tea and its processing, can solve the problems of being unable to meet the new demands of market consumption, achieve the effects of inhibiting platelet aggregation, facilitating brewing and storage, and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

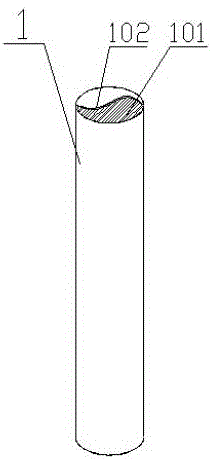

[0063] figure 1 It is a structural schematic diagram of the first embodiment of a strip-shaped tea according to the present invention. For a strip-shaped tea, the tea leaves 101 are tightly packed into strip-shaped tea using tea wrapping paper 102 .

[0064] Specifically, the tea leaves 101 are dark teas, and the strip-shaped teas are cylindrical teas 1 .

[0065] Specifically, the diameter range of the cylindrical tea 1 is 6-10mm. The height range of cylinder tea 1 is 8-12cm.

[0066] It should be noted that the strip-shaped tea can be designed as one of cylindrical tea, rectangular parallelepiped tea, triangular cylindrical tea or elliptical cylindrical tea according to the actual situation.

Embodiment 2

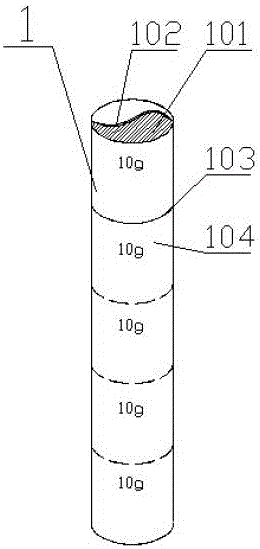

[0068] figure 2 It is a structural schematic diagram of the second embodiment of a bar-shaped tea of the present invention. The inner packaging box 102 of the cylindrical tea 1 is provided with a weight marking line 103 and a weight number marking 104, and the weight marking lines 103 are evenly distributed on the On the outer surface of the tea-wrapping paper 102, the weight number mark 104 is correspondingly arranged near the weight marking line 103 for indicating the weight of the tea leaves corresponding to the weight marking line 103.

[0069] Specifically, the diameter of the strip-shaped tea 1 is 10 mm, the height of the strip-shaped tea 1 is 100 mm, the weight marking line 103 divides the strip-shaped tea 1 into 5 equal parts, and the corresponding weight number of each equal part is marked 104 It is 10g, and users can quantify the weight of drinking according to their own needs, so as to realize scientific drinking.

Embodiment 3

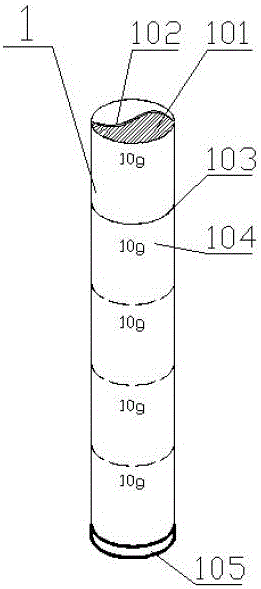

[0071] image 3 It is a structural schematic diagram of the third embodiment of a bar-shaped tea of the present invention, based on the cylindrical tea 1 in the first and second embodiments, and a tea leaf cover 105 is arranged at the bottom of the cylindrical tea 1 .

[0072] Specifically, a tea cover 105 is provided at the bottom of the cylindrical tea 1 to facilitate secondary brewing and storage of the cylindrical tea 1. When the cylindrical tea 1 is not brewed at one time, the tea cover 105 can prevent the cylindrical tea 1 from Exposed or scattered tea leaves on the end face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com