A method of using solid waste to prepare lightweight thermal insulation wall material

A technology for solid waste and thermal insulation walls is applied in the field of waste resource utilization, which can solve the problems of high cost and poor performance, and achieve the effects of reducing power consumption of grinding, reducing product cost and being beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

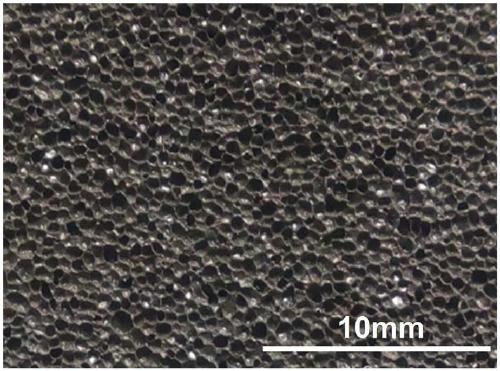

Image

Examples

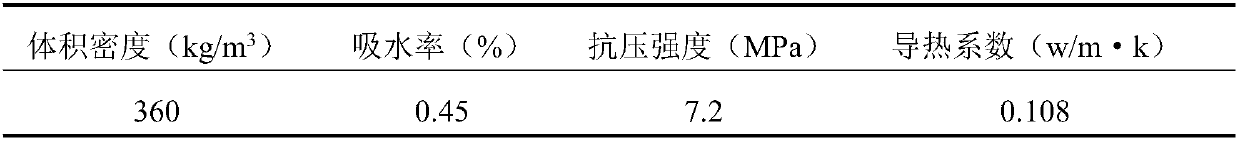

Embodiment 1

[0037] The raw materials used to prepare the dry basis are according to mass percentage: 53.3% of copper tailings, 5% of gold tailings, and 41.7% of chromium slag, and the raw materials are dried until the moisture content is lower than 2wt%. The addition amount of the composite expansion agent is 0.25% of the dry basis mass, the addition amount of the composite dispersant is 0.15% of the dry basis mass, and each raw material is accurately weighed. The weighed raw materials are placed in a ceramic ball mill, the material-to-ball ratio of the ball mill is 1:4, the mixture is mixed for 4 hours, and the particle size of the mill is <75um.

[0038] Put the prepared powder into a refractory mold covered with high-temperature paper, the thickness of the pavement is 60mm, put the mold with powder on the kiln car, and heat up to 1190°C at a heating rate of 5°C / min in the tunnel kiln , after heat preservation for 1h 20min, cool in the kiln at 8°C / min to 850min, then cool at 0.5°C / min t...

Embodiment 2

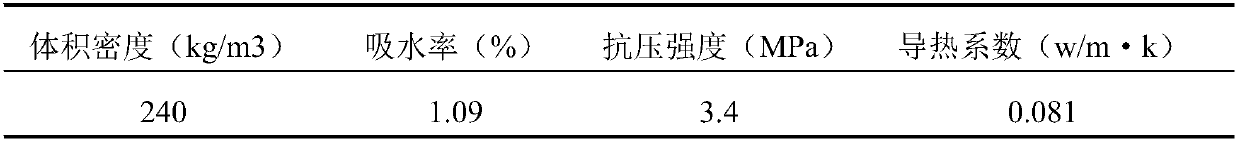

[0043] The mass percentages of raw materials used for preparing the dry basis are: 65.2% of copper tailings, 4.5% of gold tailings, and 30.3% of chrome slag, and the raw materials are dried to a moisture content of <2%. The addition amount of the composite expansion agent is 0.30wt%, the addition amount of the composite dispersant is 0.3% of the dry weight, and each raw material is accurately weighed. The temperature was raised to 1180° C. at a heating rate of 6° C. / min, and kept for 1 h 20 min. The rest of the steps were the same as in Example 1. The performance data of the prepared foam ceramic light-weight thermal insulation material are shown in Table 2 below:

[0044] Table 2 Properties of Foam Ceramic Lightweight Thermal Insulation Material

[0045]

Embodiment 3

[0047] The mass percentage of raw materials used for preparing the dry basis: 70.5% of copper tailings, 8.5% of gold tailings, and 21% of chromium slag, and the raw materials are dried to a moisture content of <2%. The addition amount of the composite expansion agent is 0.40wt%, the addition amount of the composite dispersant is 0.5% of the dry weight, and each raw material is accurately weighed. The temperature was raised to 1160° C. at a heating rate of 5° C. / min, and kept for 1.5 hours. The rest of the steps were the same as in Example 1. The performance data of the prepared foam ceramic light-weight thermal insulation material are shown in Table 3 below:

[0048] Table 3 Properties of Foam Ceramic Lightweight Thermal Insulation Material

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com