Rapidly degradable PVC material as well as preparation method and application thereof

A PVC material and rapid degradation technology, applied in the field of degradable PVC composite materials, can solve the problems of uncontrollable degradation speed, low practicability, complicated operation process, etc., and achieve harmless treatment, good biocompatibility, bacterial growth inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

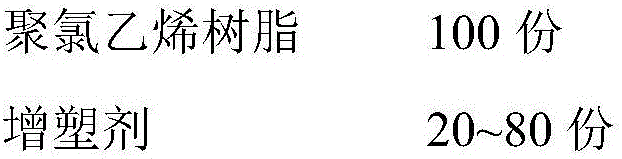

[0029] Formula: (parts by weight)

[0030]

[0031] Degradation accelerator A is polyglycolic acid with a number average molecular weight of 200,000;

[0032] The degradation accelerating preparation B is β-crystalline polylactic acid;

[0033] Preparation steps:

[0034] (1) Add PVC, plasticizer, and ESO into the high-speed mixer in turn, heat and stir at a low speed of 50rpm to 90°C, then heat stabilizer and medical silicone oil, and run at 400rpm, and add degradation acceleration aids A and B after the temperature reaches 105°C . Stir continuously to 140°C and discharge to the cooling mixer with a rotation speed of 35rpm. When the temperature of the material is cooled to 40°C, the material is discharged.

[0035] (2) The material obtained in step (1) is granulated using a twin-screw extruder. The screw speed of the main engine is 70rpm, the temperature of each section of the extruder: the first section is 120°C, the second section is 130°C, the third section is 150°...

Embodiment 2

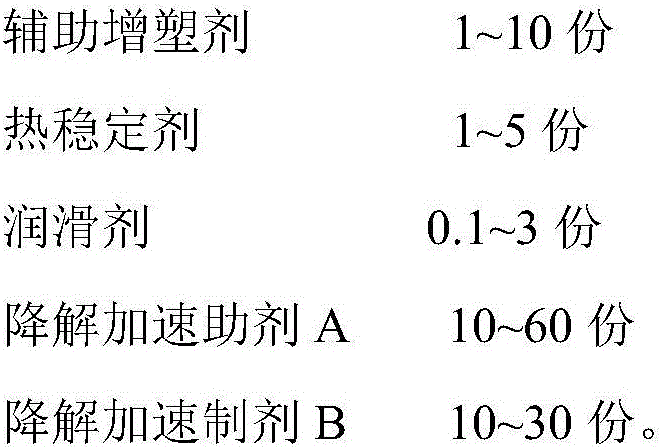

[0037] Formula: (parts by weight)

[0038]

[0039] The degradation accelerator A is polyglycolic acid, and the number average molecular weight is 10,000;

[0040] The degradation accelerating preparation B is β-crystalline polylactic acid;

[0041] The preparation method is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com