Half-dry half-wet type water cooling system oriented to combined-type combustion chamber of two-stroke aviation heavy oil piston engine

A piston engine, semi-dry and semi-wet technology, applied to the cooling of the engine, engine components, machines/engines, etc., can solve the problems of high working noise, high mechanical load, and high cooling capacity requirements, and achieve the promotion of temperature field balance and cooling The effect of improving capacity and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below according to the accompanying drawings.

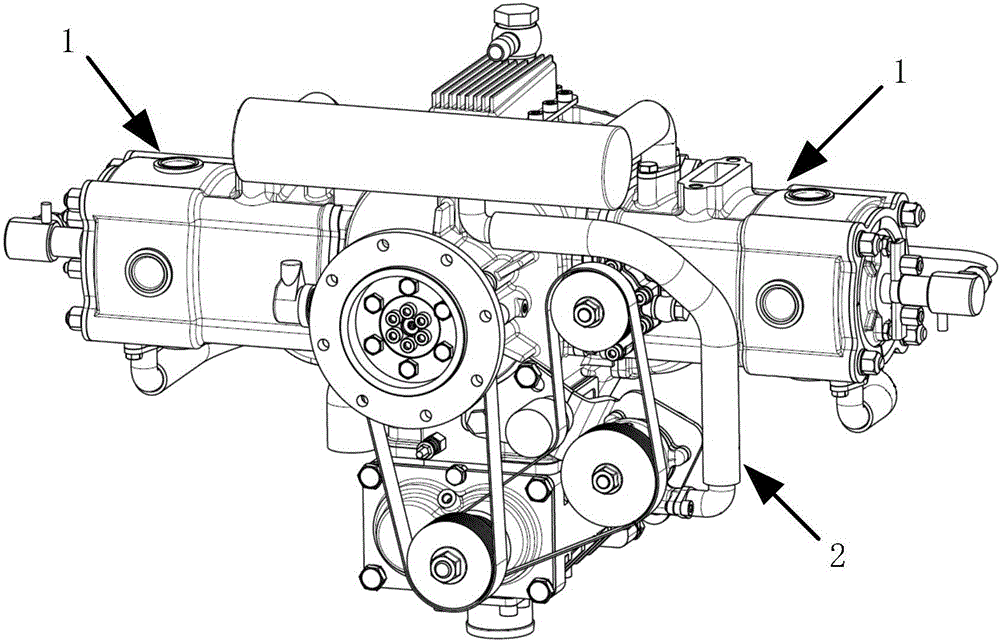

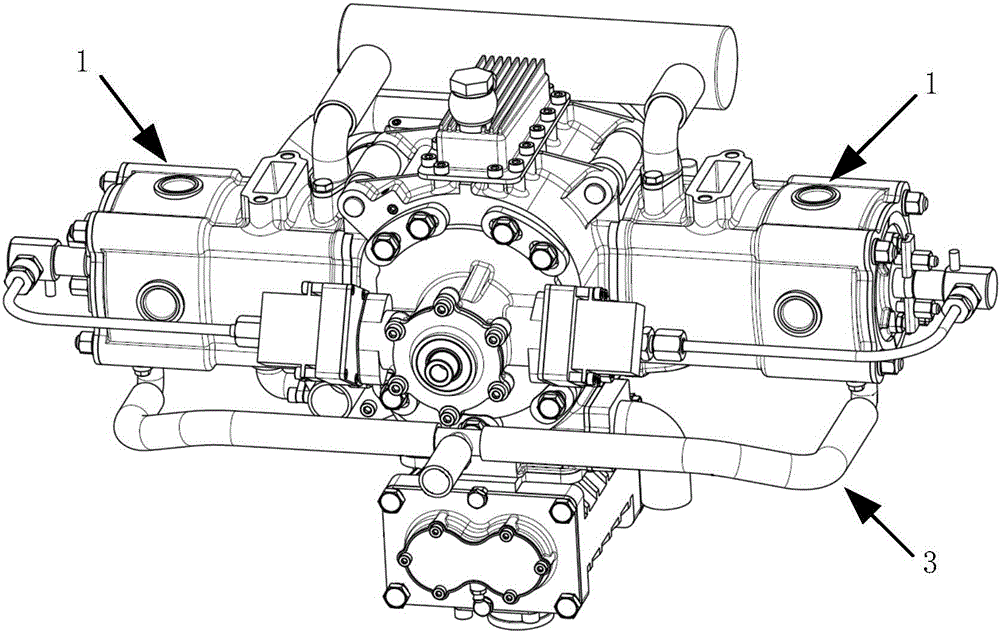

[0039] The present invention is oriented to the semi-dry and semi-wet cooling system of the body of the two-stroke aviation heavy oil piston engine. The cooling water channel is cast in the combined combustion chamber area of the cylinder 1 of the single-cylinder piston engine, and the cooling in the cooling water channel is realized through the water inlet system 2 and the water outlet system 3. Injection and removal of water, thereby implementing water cooling for combined combustion chambers of single-cylinder piston engines, e.g. figure 1 , figure 2 shown.

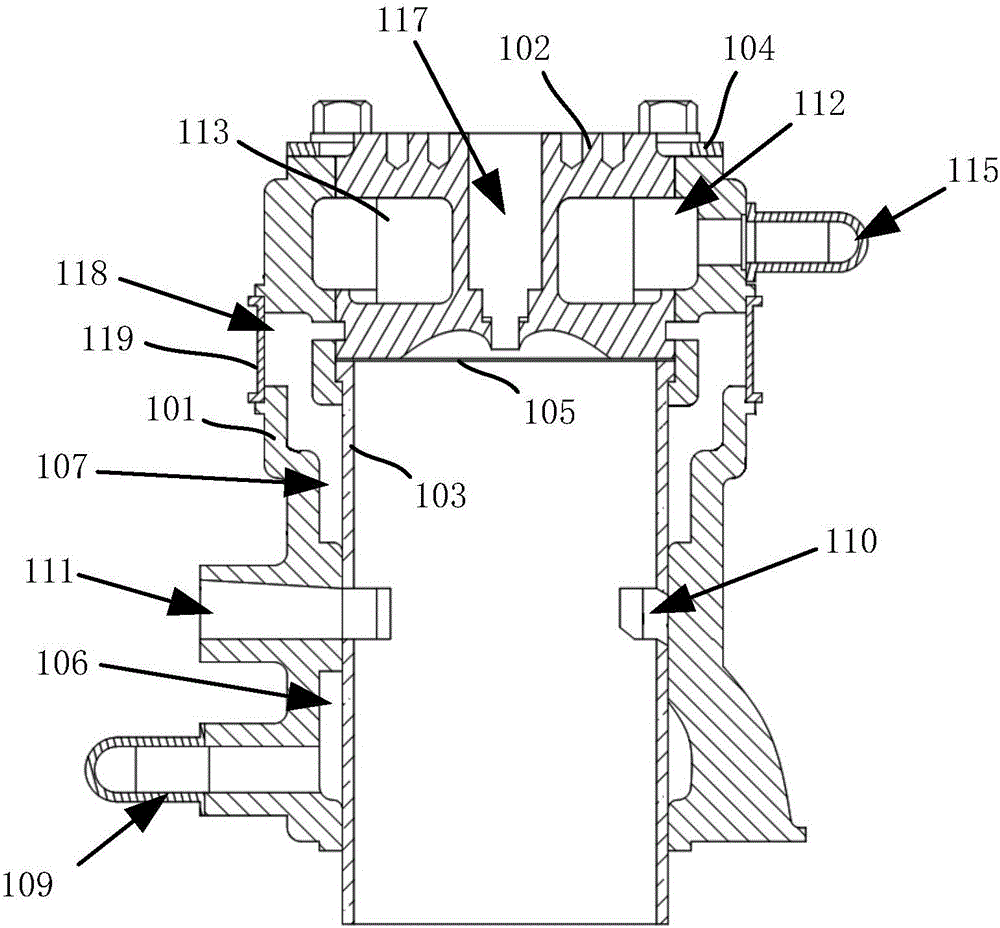

[0040] Above-mentioned single-cylinder piston engine cylinder comprises cylinder block 101, cylinder head 102, cylinder liner 103 and cylinder head pressure plate 104, as image 3 shown. Wherein, the cylinder block 101 is a cylindrical structure, and the inner wall of the top end is designed with inter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap