W-shaped boiler oil-saving and wind-resistant type bispin burner port ignition device

An ignition device and burner technology, which is applied in the direction of ignition by guided flame, combustion ignition, combustion type, etc., can solve the problems of weak ignition effect of oil flame, long distance, high fuel consumption of W-type boiler ignition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

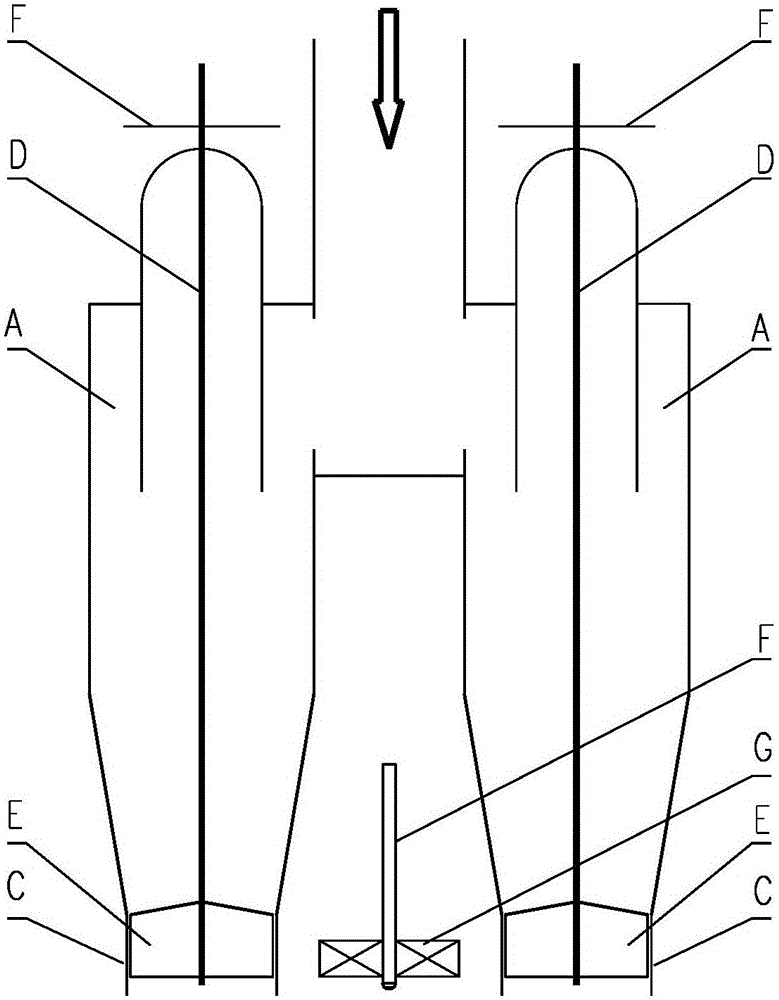

[0017] figure 1 It is a structural schematic diagram of an existing oil gun ignition device for a W-type boiler, and its structure has been described above, and will not be repeated here.

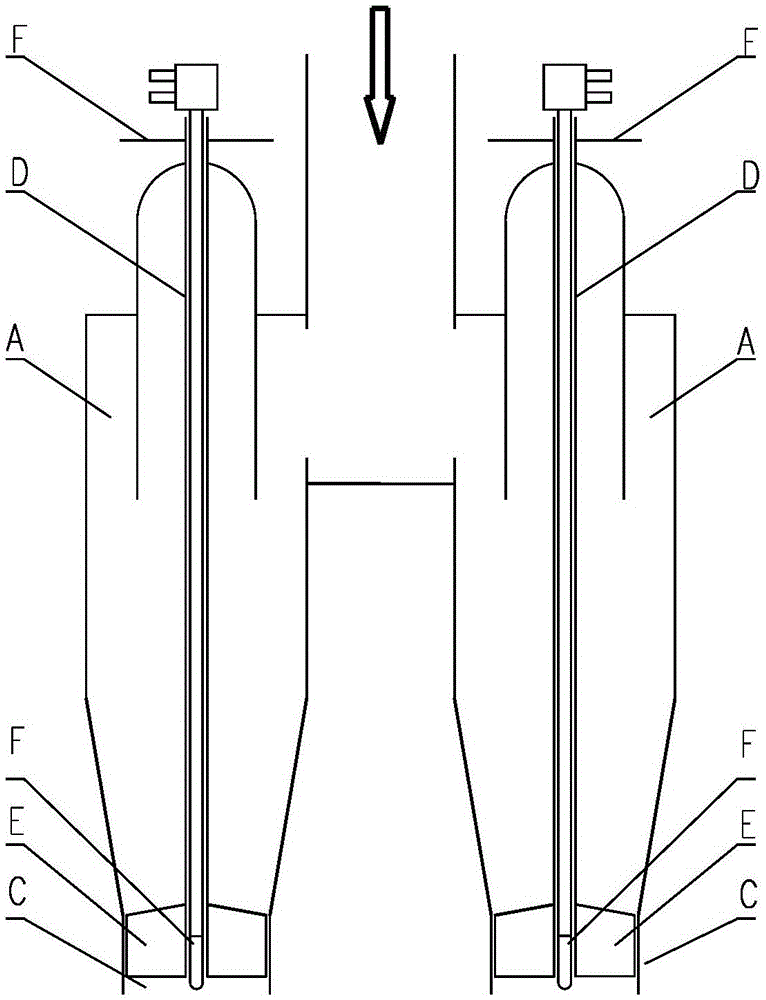

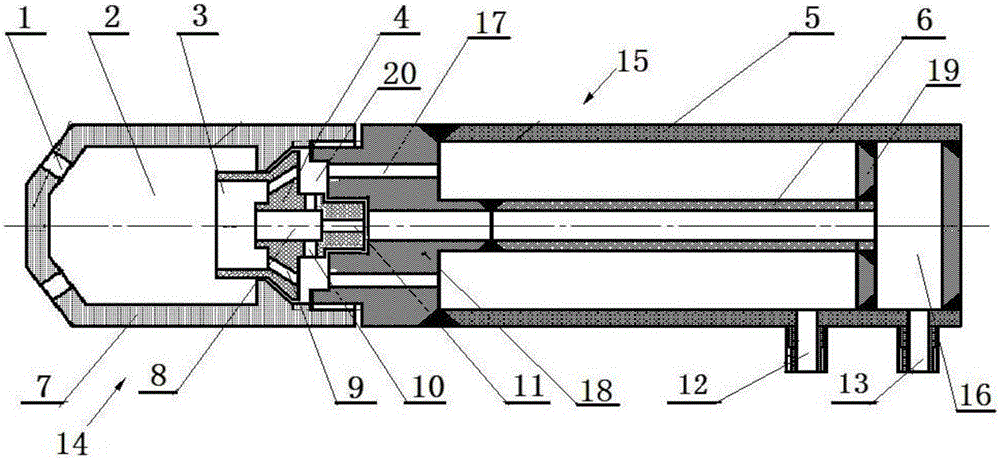

[0018] Figure 2~3 The oil-saving and wind-resistant dual-rotary burner ignition device for a W-type boiler shown in , includes two sets of symmetrically arranged pulverized coal cyclone separators A and ignition spray guns B, and the elbow end of the pulverized coal cyclone separator A is provided with a The hanging pipe D of the pulverized coal nozzle C, the pulverized coal nozzle C is provided with a derotation blade E, and the derotation blade E is set on one end of the suspension pipe D, and the other end of the suspension pipe D is provided with a suspension pipe adjustment wheel F. In that: the hanging tube D is a hollow tubular structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com