Front sub-frame fall-off mechanism strength test device and method

A strength test and front sub-frame technology, which is applied in the testing of machine/structural components, vehicle testing, measuring devices, etc., can solve the problems of high cost, difficulty in accurately testing the shedding strength of the front sub-frame, and high cost, and achieve The effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

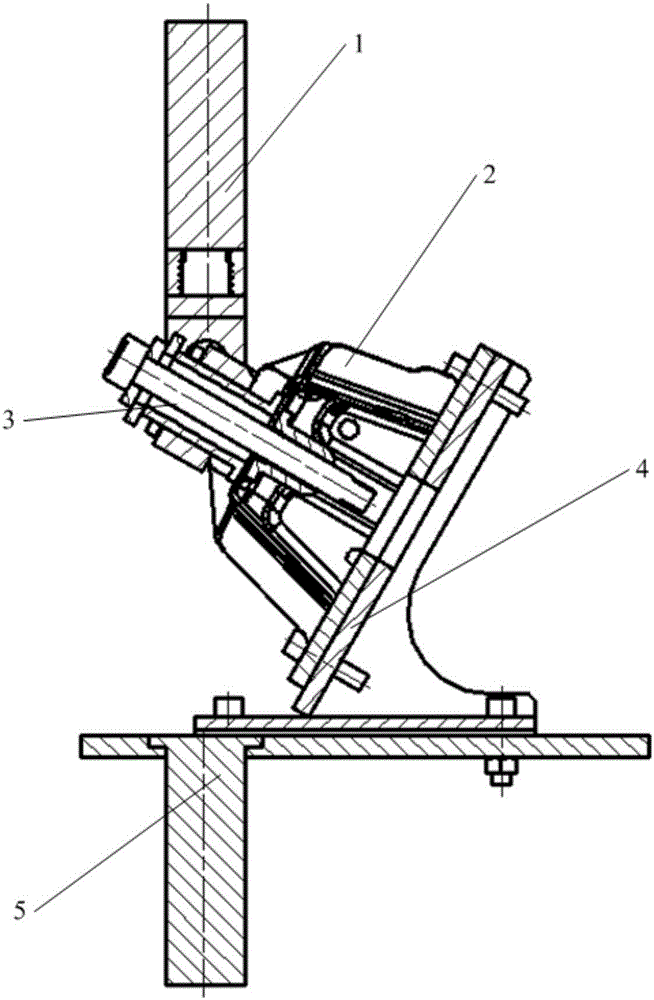

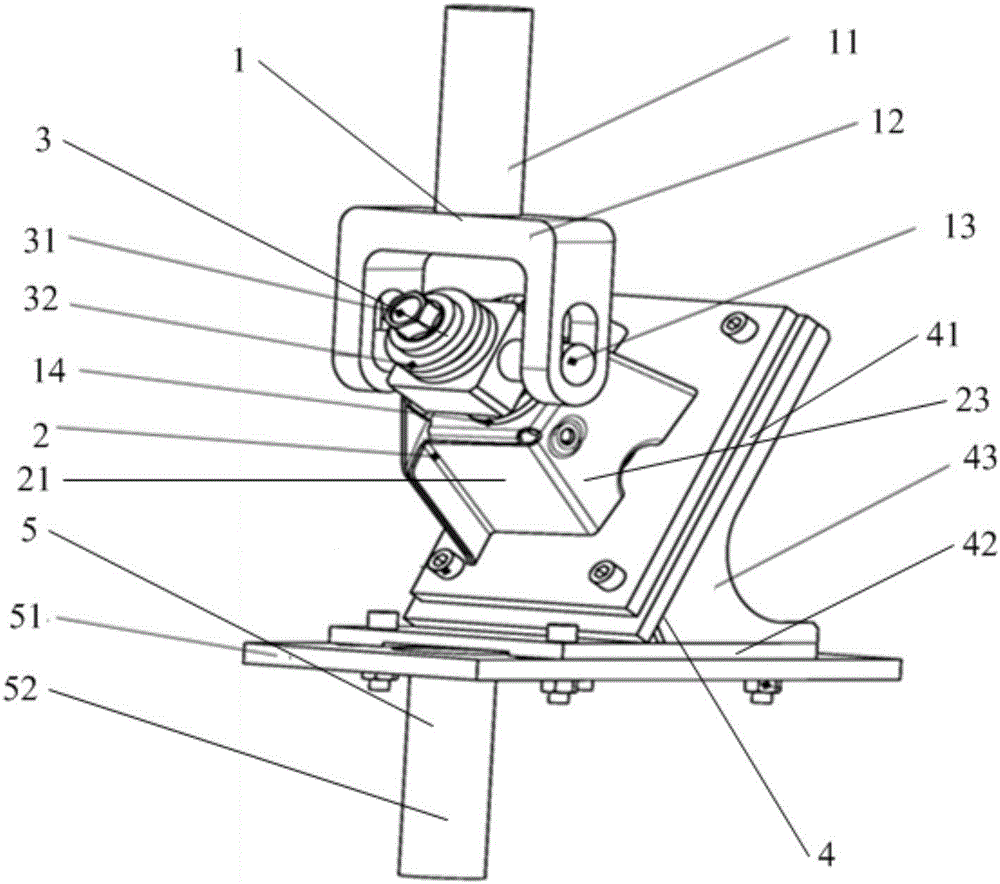

[0056] Figure 1A It is a schematic diagram of a strength test device for a front sub-frame shedding mechanism shown according to an exemplary embodiment, as shown in Figure 1A As shown, the equipment includes:

[0057] Pull-off mechanism assembly 1, body sample 2, connector 3, corner seat assembly 4 for static strength test and lower base assembly 5;

[0058] Such as Figure 1B As shown, the corner seat assembly 4 for the static strength test includes an inclined surface 41 and a base 42, and the inclined angle of the inclined surface 41 is equal to the angle between the force direction of the mounting point of the front sub-frame and the plane where the automobile is located when the automobile collides. Complementary angle;

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap