Test piece component for III-type dynamic fracture toughness test of fragile material and test method

A brittle material, fracture toughness technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve the problems of no feasible type III dynamic fracture toughness test method, difficult production, poor practicability, etc., to reduce the number of test pieces. The effect of damage, low processing difficulty and reasonable position setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

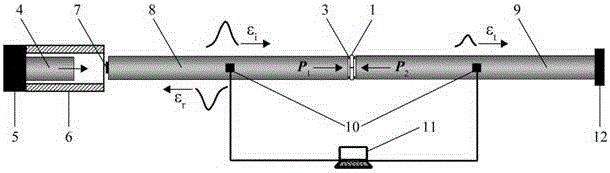

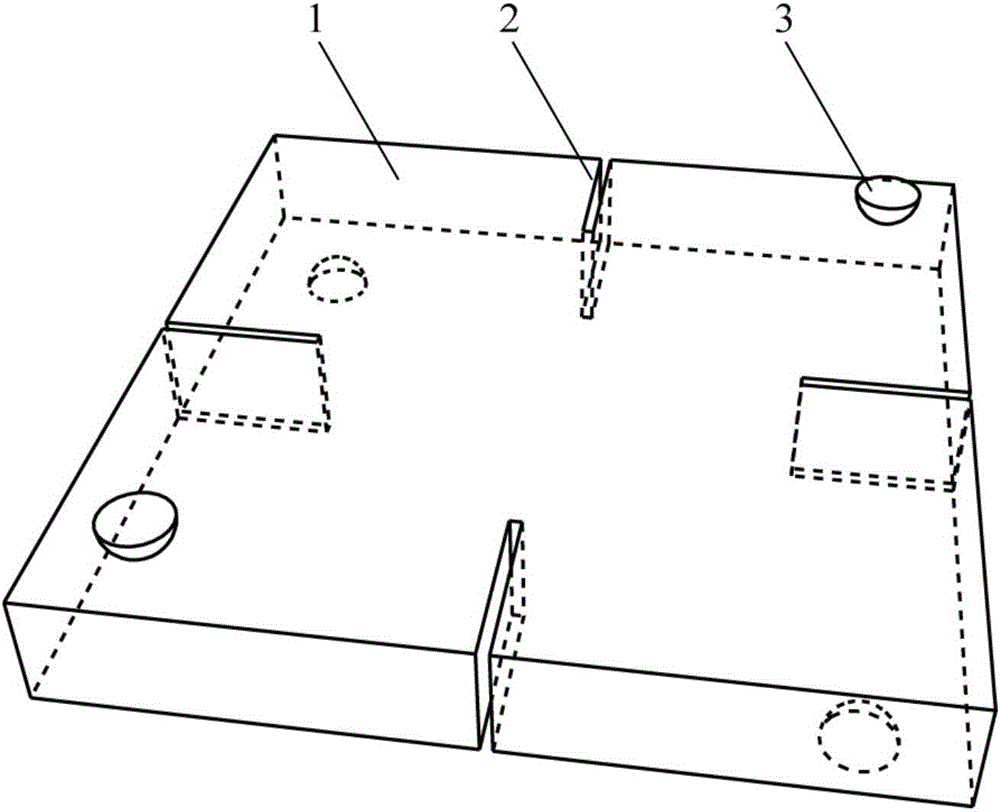

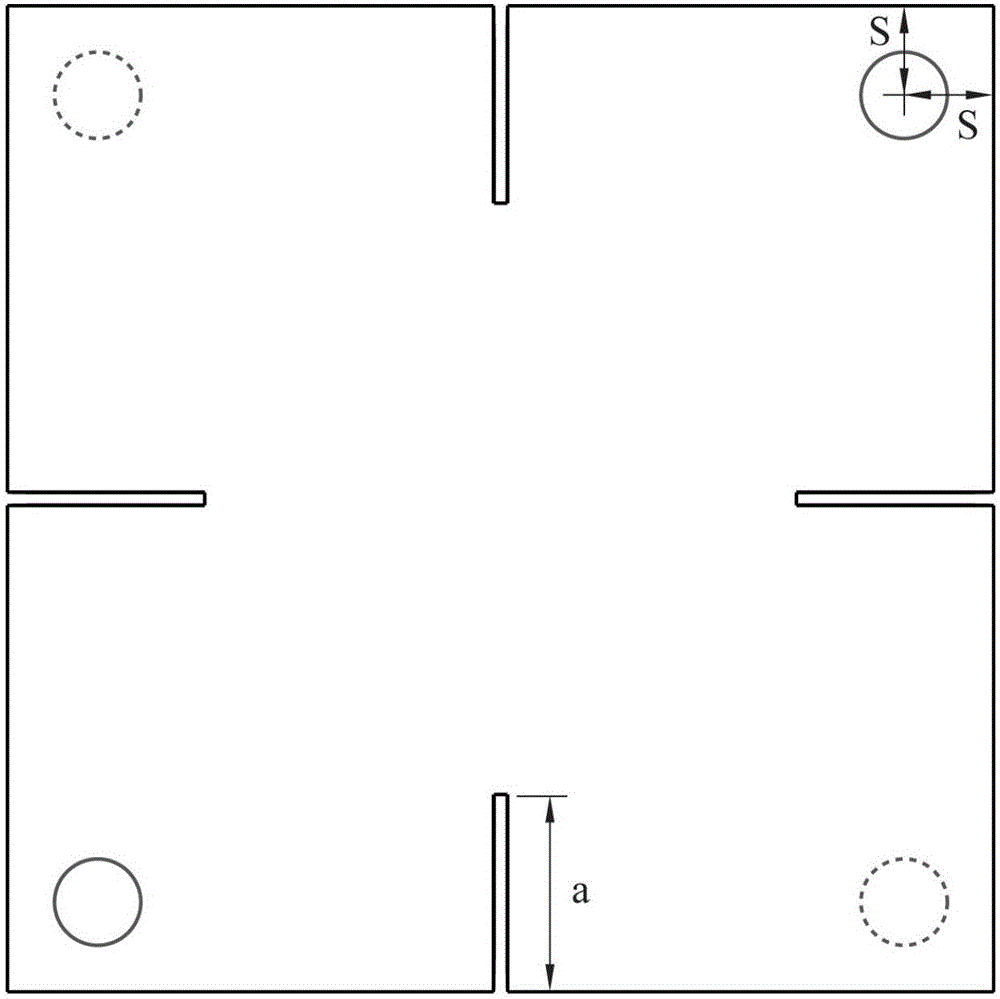

[0042] In the present embodiment, the structural representation of the specimen assembly used for the Type III dynamic fracture toughness test of brittle materials is as follows Figure 1~3 As shown, the specimen body of the specimen assembly is made by cutting a concrete block with a diamond slicer.

[0043] The test piece assembly for the Type III dynamic fracture toughness test of brittle materials consists of a test piece body 1 with a notch 2 and an indenter 3 against the test piece body. The test piece body is a square plane plate, and the test piece The side length of the body is L=70mm, the thickness of the test piece body is B=10mm, the slot 2 on the body of the test piece is four slots with the same shape, which are respectively located at the positions of the two symmetry lines on the four sides of the body of the test piece , the direction of the groove is along the thickness direction of the specimen body and the direction of the symmetry line, the opening of the ...

Embodiment 2

[0045] In the present embodiment, the structural representation of the specimen assembly used for the Type III dynamic fracture toughness test of brittle materials is as follows Figure 1~3 As shown, the specimen body of the specimen assembly is made by cutting a concrete block with a diamond slicer.

[0046] The test piece assembly for the Type III dynamic fracture toughness test of brittle materials consists of a test piece body 1 with a notch 2 and an indenter 3 against the test piece body. The test piece body is a square plane plate, and the test piece The side length of the body is L=100mm, the thickness of the test piece body is B=20mm, and the cut grooves 2 located on the test piece body are four cut grooves with the same shape, which are respectively located at the positions of the two symmetry lines on the four sides of the test piece body , the direction of the groove is along the thickness direction of the specimen body and the direction of the symmetry line, the op...

Embodiment 3

[0048] In the present embodiment, the structural representation of the specimen assembly used for the Type III dynamic fracture toughness test of brittle materials is as follows Figure 1~3 As shown, the specimen body of the specimen assembly is made by cutting a rock block with a diamond slicer.

[0049] The test piece assembly for the Type III dynamic fracture toughness test of brittle materials consists of a test piece body 1 with a notch 2 and an indenter 3 against the test piece body. The test piece body is a square plane plate, and the test piece The side length of the body is L=50mm, the thickness of the test piece body is B=5mm, and the cut grooves 2 on the test piece body are four cut grooves with the same shape, which are respectively located at the positions of the two symmetry lines on the four sides of the test piece body , the direction of the groove is along the thickness direction of the specimen body and the direction of the symmetry line, the opening of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rod diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com