A gear unilateral forming machining method combined with a custom tool and a specific path

A technology of forming processing and single gear, which is applied in the direction of belt/chain/gear, gear teeth, components with teeth, etc., can solve the problems of high tool material cost, large tool diameter, sacrifice time cost, etc., and achieve low cost , The effect of small knife output and low material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

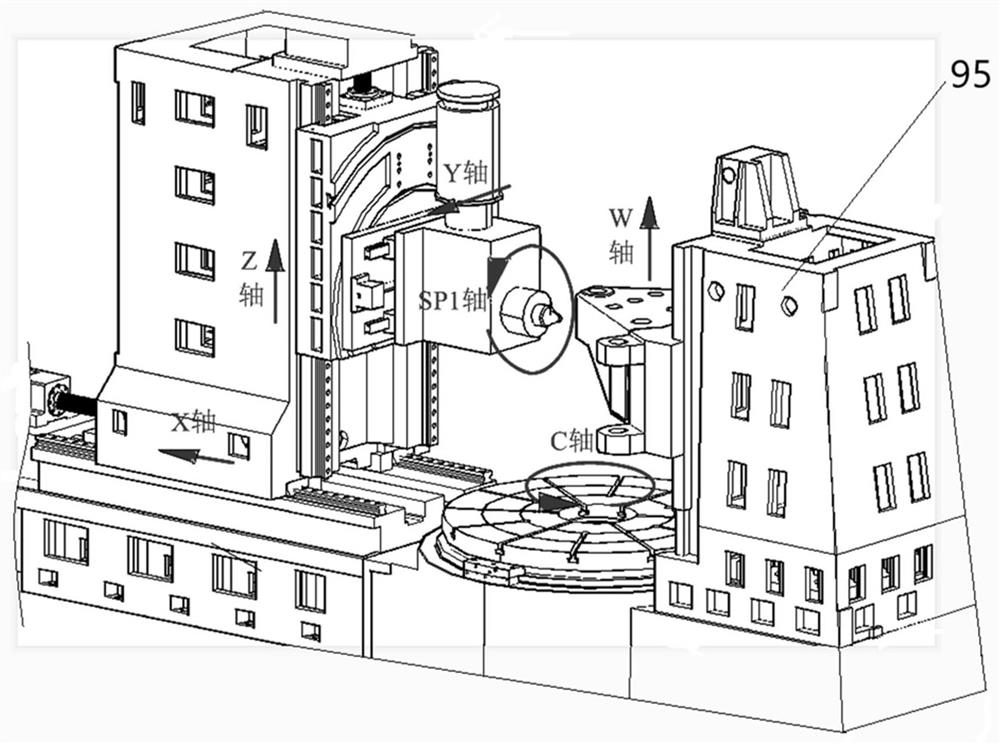

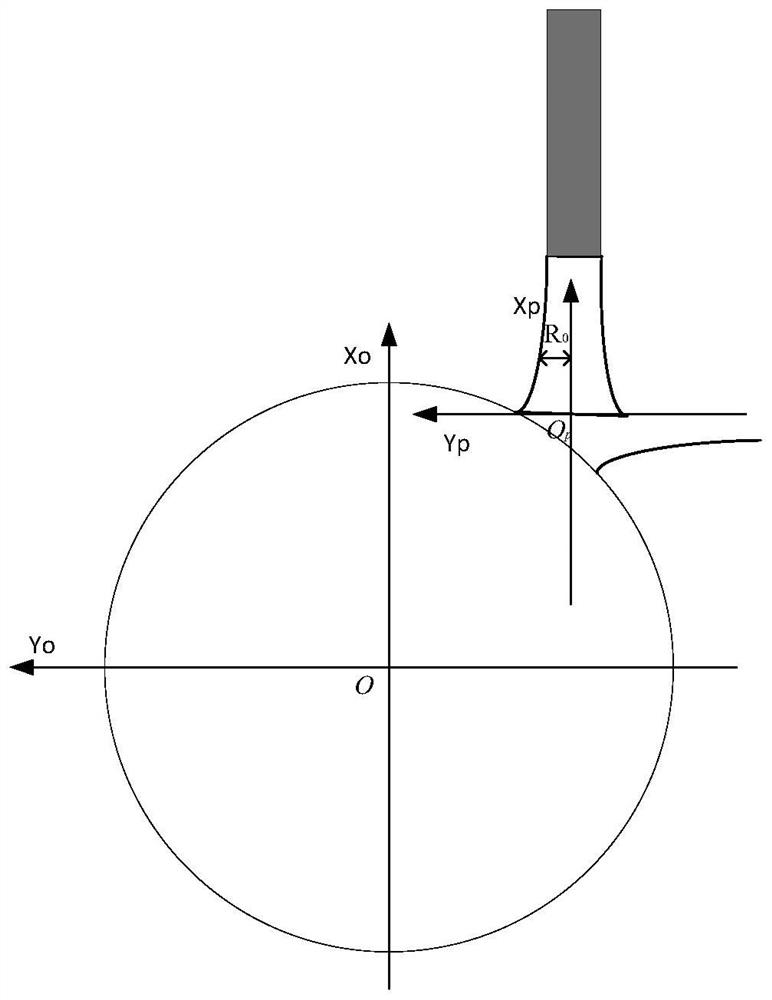

[0043] A method for unilateral forming of involute helical gears and herringbone teeth combined with a customized tool and a specific path, suitable for applications such as figure 1 machine shown.

[0044] The specific implementation steps are as follows:

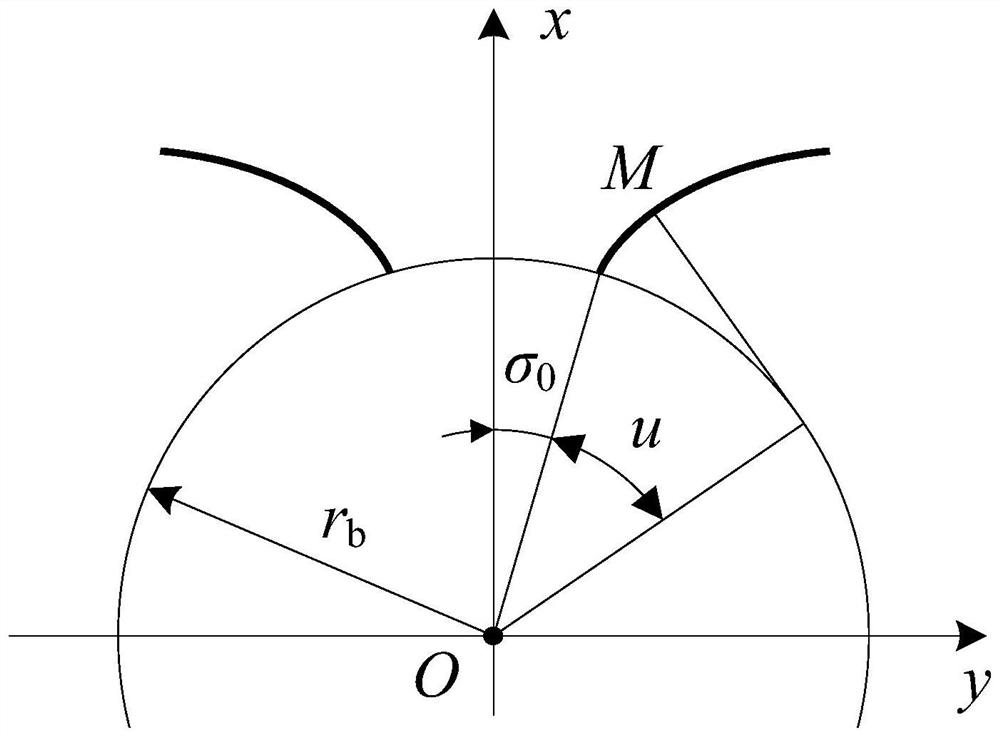

[0045] Establish the gear end face coordinate system S (O-X, Y), such as figure 2 shown.

[0046] According to the gear parameters, calculate the involute contour of the gear end face and the tangent vector at the index circle.

[0047] Calculate the angle between the tangent vector and the X-axis, which is the C-axis rotation angle at the machining position relative to the theoretically calculated position.

[0048] The coordinates (x, y) of point M at the involute indexing circle of the gear end face are:

[0049]

[0050] where r b is the radius of the base circle, σ 0 is the half angle of the tooth slot, and u is the rolling angle at the index circle;

[0051] The tangent vector at the index circle is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com