High-capacity and metal-insensitive double layer chip-free tag antenna

A tag antenna, chipless technology, applied in antennas, slot antennas, antenna components, etc., can solve the problems of magnetic field line deformation, energy acquisition, and failure to work normally, and achieve the effect of reducing size and improving coding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

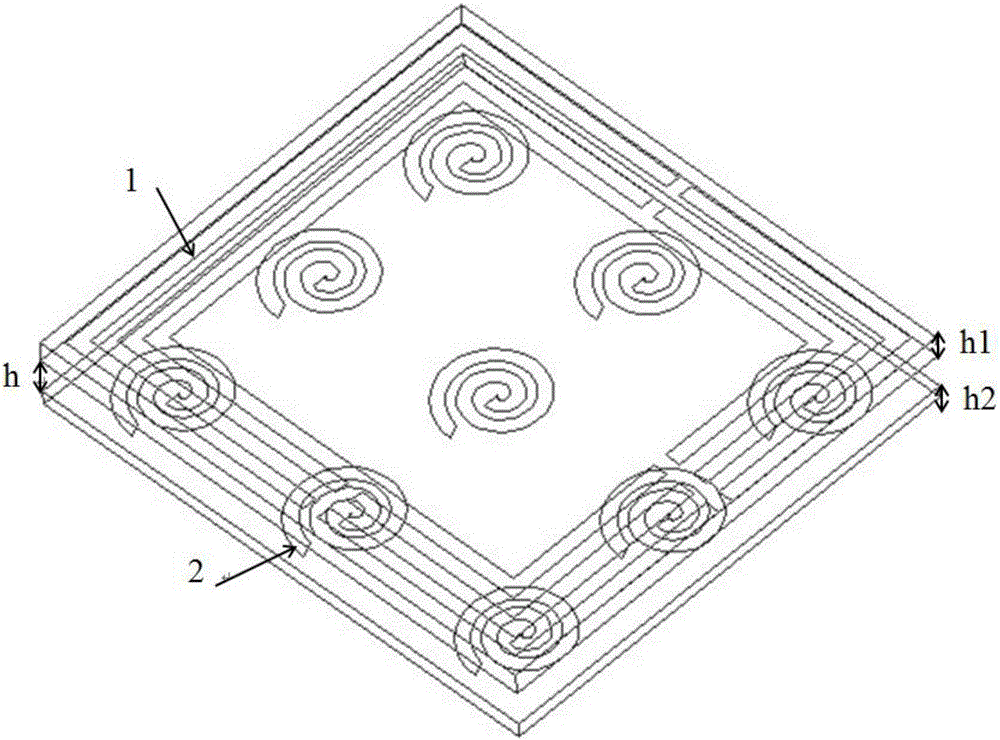

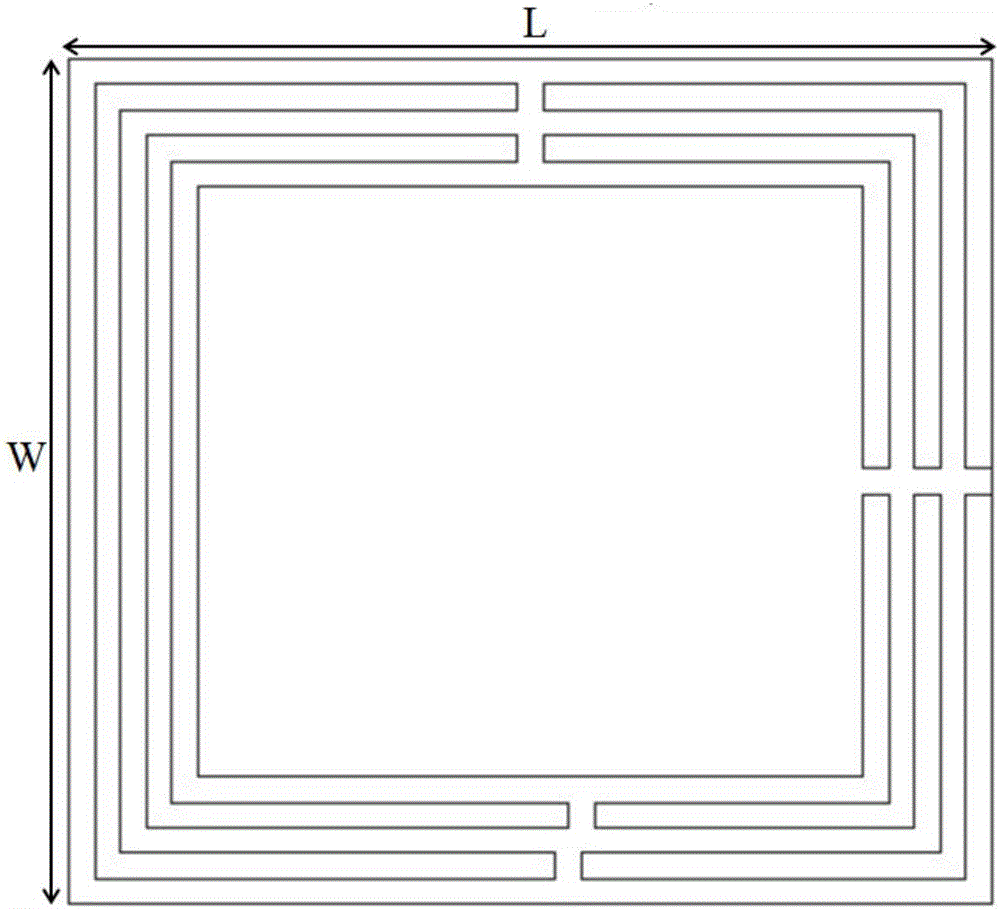

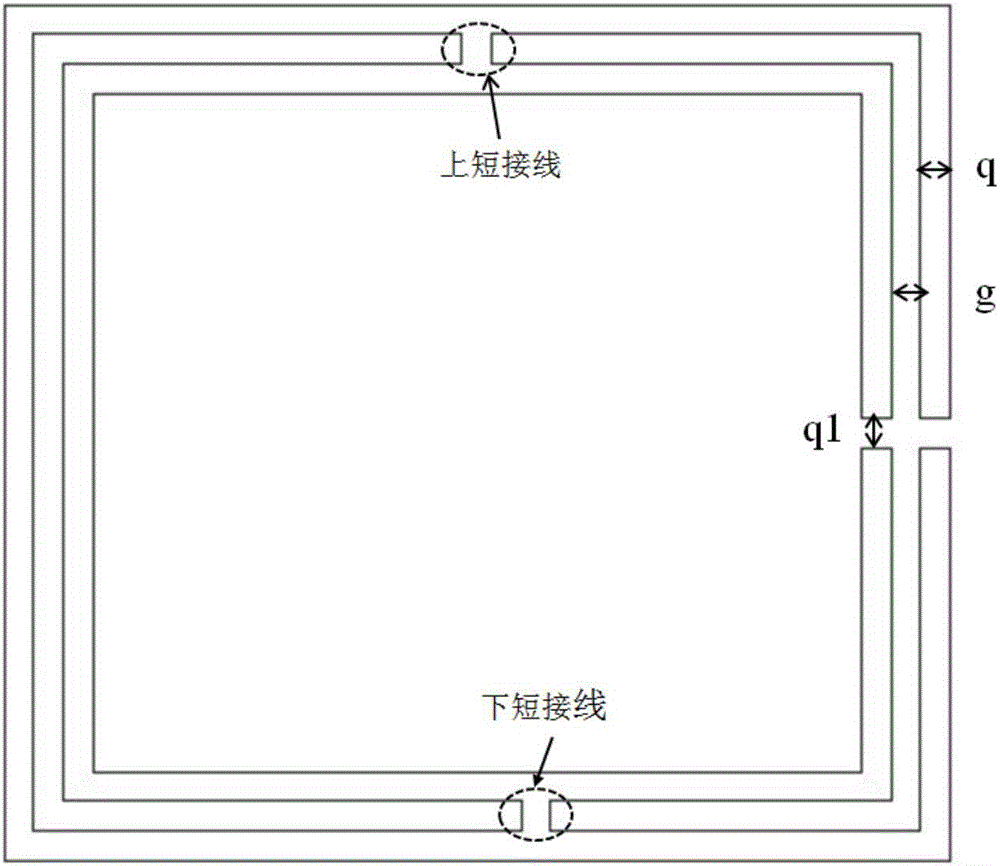

[0029] This embodiment discloses a high-capacity and metal-insensitive double-layer chipless tag antenna, which is used in a radio frequency identification system chipless tag antenna, including an upper dielectric substrate, a lower dielectric substrate, a split ring resonator and a spiral resonator . The split ring resonator and the spiral resonator are printed on the upper dielectric substrate and the lower dielectric substrate respectively, and the split ring resonator and the spiral resonator have different heights in the same vertical plane distributed.

[0030] In a specific embodiment, the split ring resonator is located on the upper surface of the upper dielectric substrate, the spiral resonator is located on the lower surface of the lower dielectric substrate, and the gap between the upper dielectric substrate and the lower dielectric substrate is Air spaced at a height of 0.5mm. The tag antenna disclosed in the present invention utilizes a double-layer structure i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com