A multi-segment barcode nanorod and its preparation method

A nano-rod and barcode technology, applied in the field of nano-coding materials, can solve problems such as limiting coding capacity, and achieve the effects of increasing coding capacity, low cost, and large coding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Multi-segment barcode nanorods, the preparation process of which is:

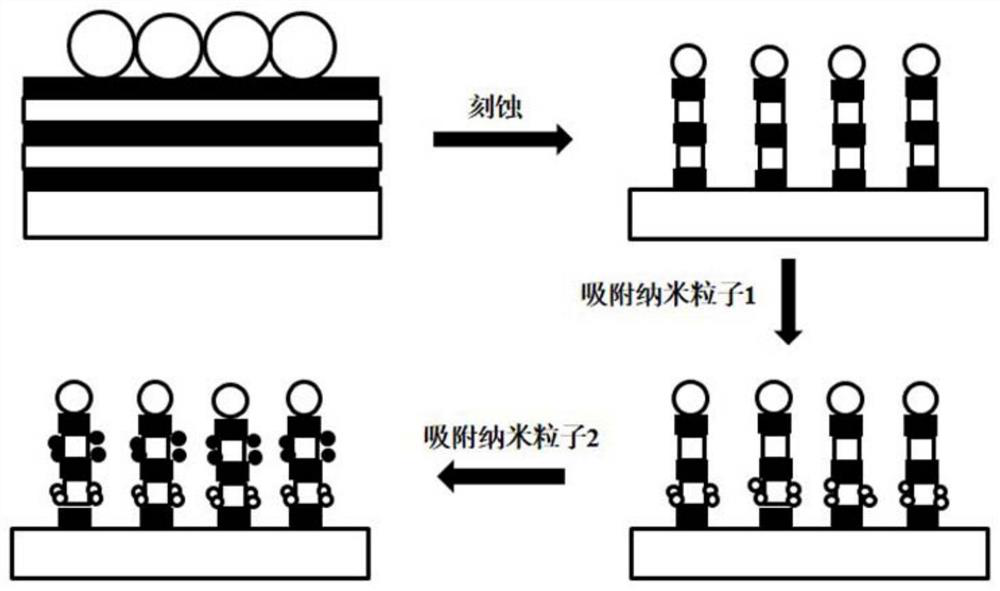

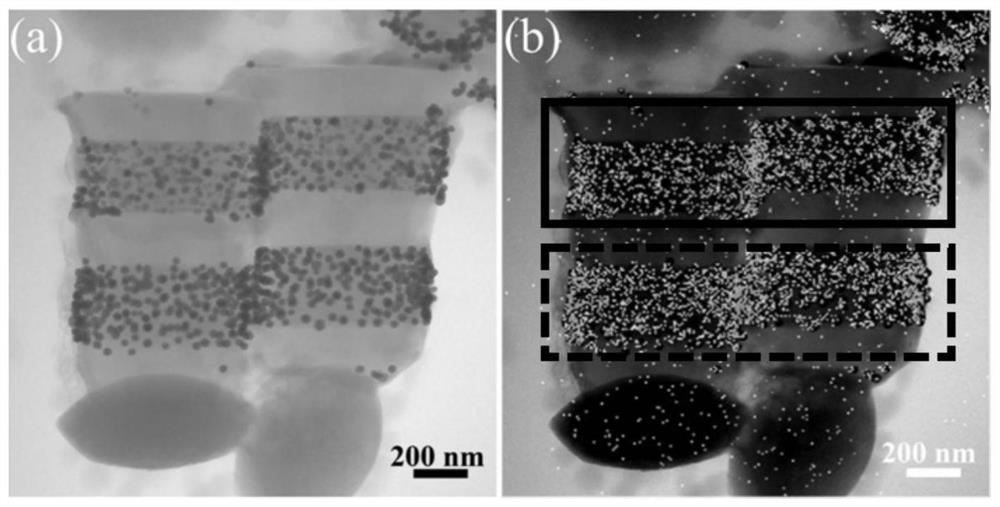

[0032] (1) The colloidal crystal etching method is used to construct multi-segment nanorod arrays. The construction flow chart is as follows figure 1 As shown, the details are as follows: firstly, different polymer solutions are sequentially deposited to form films on the surface of the same substrate (the substrate is a silicon substrate) by spin coating, and then silicon dioxide microspheres are assembled on the surface of the five-layer polymer film, and then the compact The stacked silica microspheres were etched into a non-close packed array by plasma etching technology, and finally the etched silica microspheres were used as a mask to etch the underlying five-layer polymer film to produce multi-segment nanometers. rod array; wherein, the average diameter of silica microspheres is 800nm, and different polymer solutions are: polystyrene (solvent is toluene), protonated poly(4-vinylpyridine) (solv...

Embodiment 2

[0037] Multi-segment barcode nanorods, the preparation process of which is:

[0038] (1) Colloidal crystal etching method was used to construct multi-segment nanorod arrays: firstly, different polymer solutions were sequentially deposited on the surface of the same substrate (the substrate was a silicon substrate) to form films by the drop coating method, and then deposited on the surface of the three-layer polymer film Assemble polystyrene microspheres, and finally use polystyrene microspheres as a mask to etch the lower three-layer polymer film to make multi-segment nanorod arrays; wherein, the average diameter of polystyrene microspheres is 300nm, and different polymers The solution is as follows: polyacrylic acid solution (solvent is ethanol), polystyrene (solvent is toluene) and polymethacrylic acid N,N-dimethylaminoethyl ester solution (solvent is chloroform) for each layer of polymer film deposited , the control base is tilted at a certain angle relative to the horizont...

Embodiment 3

[0043] Multi-segment barcode nanorods, the preparation process of which is:

[0044] (1) Colloidal crystal etching method is used to construct multi-segment nanorod arrays: firstly, different polymer solutions are sequentially deposited on the surface of the same substrate (the substrate is a silicon substrate) to form films by spin coating, and then deposited on the surface of the three-layer polymer film Assemble polystyrene microspheres, and finally use polystyrene microspheres as a mask to etch the underlying three-layer polymer film to make multi-segment nanorod arrays; wherein, the average diameter of polystyrene microspheres is 1 μm, and different polymers The product solution is followed by: thiol cross-linked polyamino acid solution (solvent is water), polymethacrylate N,N-dimethylaminoethyl ester solution (solvent is chloroform) and photoresist solution (product model is AZ4620 ); each time a polymer film is deposited, the substrate is controlled to incline at a cert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com