Vehicle film pasting equipment and vehicle film pasting method

A car film and car film technology, applied in packaging and other directions, can solve problems such as uneven paste, uneven car surface, and corrosion marks on the car surface, so as to reduce labor costs, promote the car beauty industry, and be more operable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

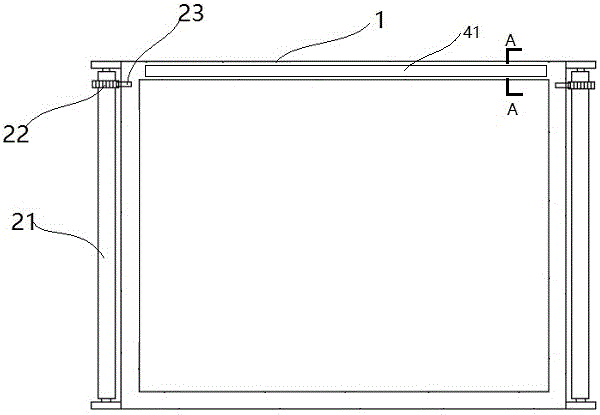

Embodiment 1

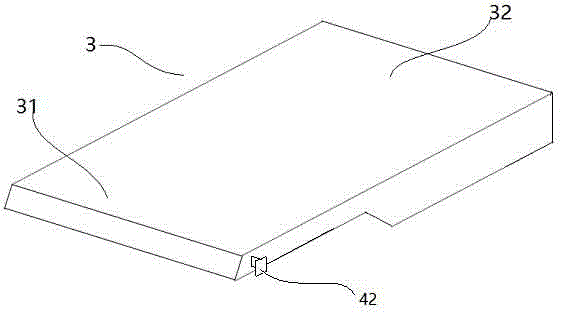

[0044] An automobile film sticking device includes a clamping device for fixing the automobile film, an air injection system for spraying the automobile film, and a drive system for controlling the clamping device and the air injection system. The drive system includes a mechanical arm and a control system. The clamping device also includes a tension device for tensioning the automobile film. In this example, if figure 1 As shown, the clamping device is a film fixed frame 1, and the tension device includes a rotating shaft 21 arranged on the film fixed frame 1 and a ratchet mechanism, and the ratchet mechanism includes a ratchet 22 arranged at the end of the rotating shaft 21 and a The ratchet 23 on the film fixing frame 1 and used in conjunction with the ratchet 22, the car film is pasted on the rotating shaft 21 at both ends of the film fixing frame 1, and the ratchet 22 cooperates with the ratchet 23 so that the rotating shaft 21 can only rotate in one direction, thereby t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com