Bracket riveting press with unloading and bearing automatic feeding

A technology of automatic feeding and riveting press, applied in conveyor objects, metal processing, metal processing equipment, etc., can solve the problems of low output stability, high processing cost, low efficiency, etc., and achieve stable and automated equipment operation. The effect of high degree and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

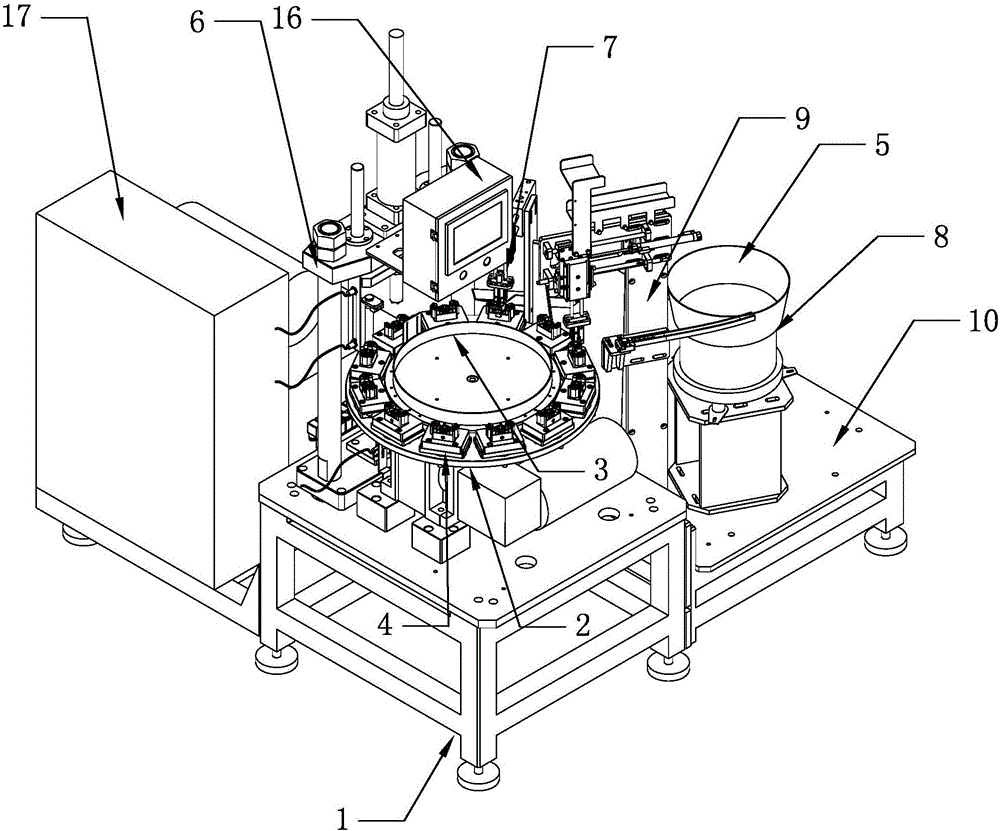

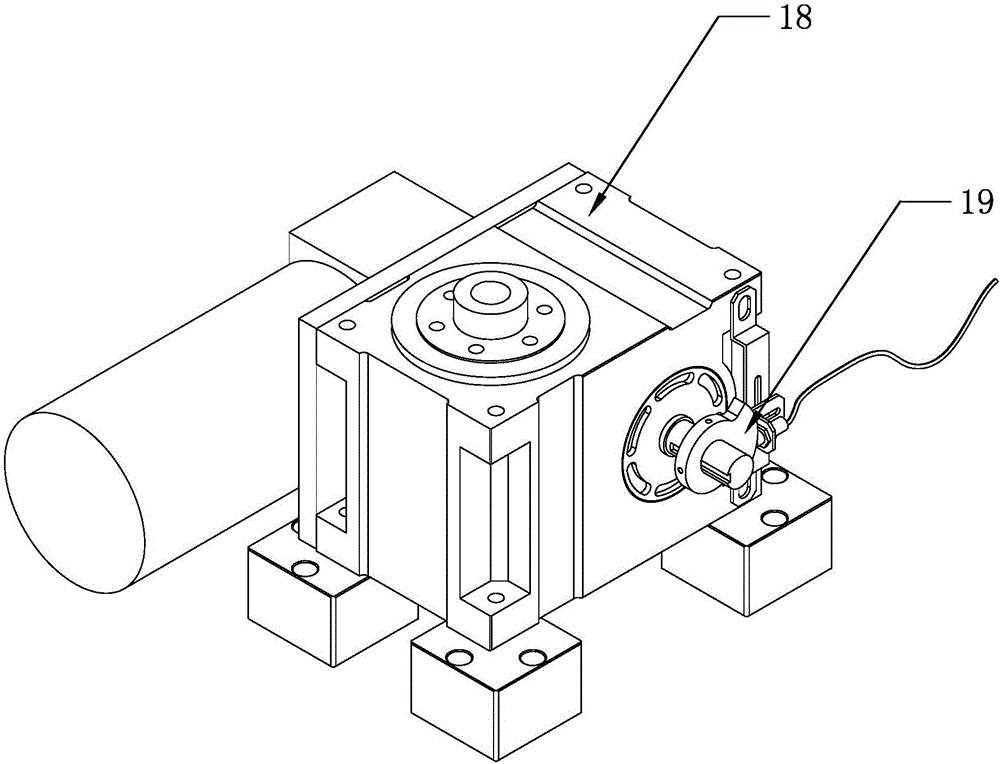

[0021] refer to Figure 1 to Figure 5 , a bracket riveting machine with unloading and bearing automatic loading of the present invention, comprising a frame 1, an indexing turntable 2 is arranged on the frame 1, preferably, the indexing turntable 2 is divided by a cam The cam divider 18 is driven to rotate, and the cam divider 18 is driven by a box-type worm gear reducer, and the cam divider 18 is provided with an induction cam 19, and the curved section of the contour surface of the induction cam 19 drives the indexing turntable 2 to rotate, and the straight section Make indexing dial 2 stationary. The cam divider 18 is adopted, which has the advantages of simple structure, stable transmission, high precision of output division and long service life, and is very suitable for this automatic equipment for intermittent division and rotation.

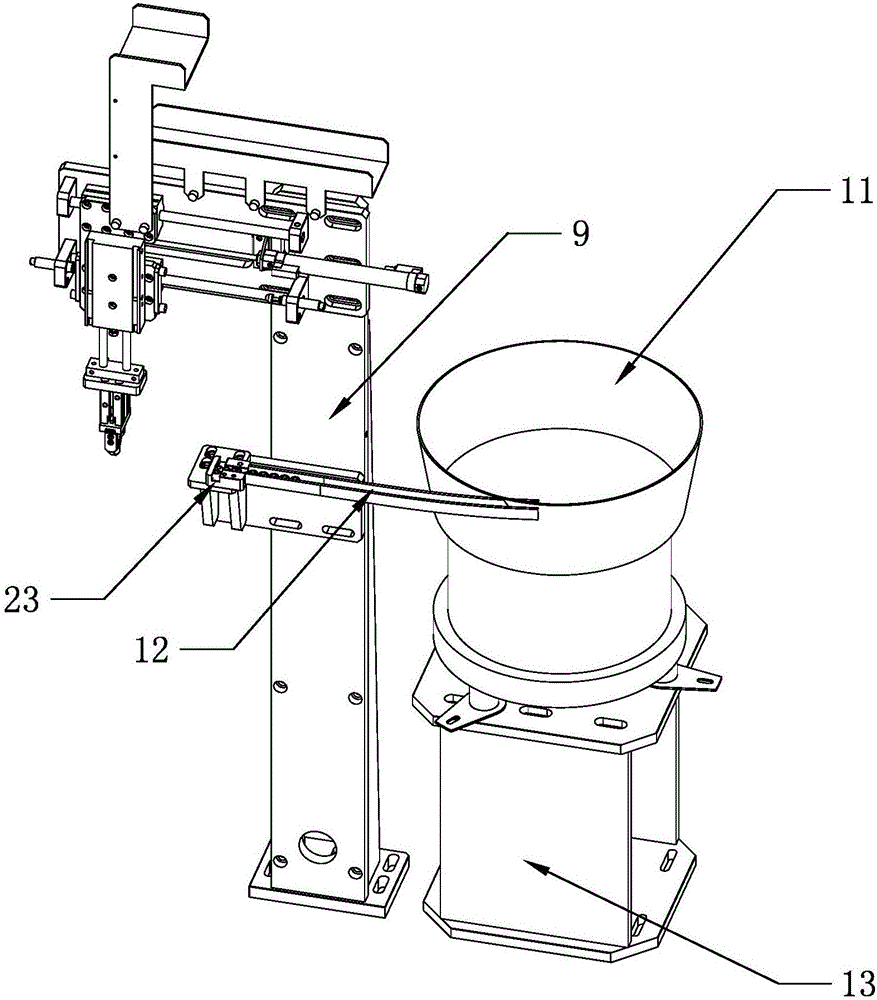

[0022] The center of the indexing turntable 2 is provided with a material tray 3, and oil cotton, pressing pieces and brackets are place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com