Transparent polypropylene resin with strong impact resistant performance

A technology of transparent polypropylene and polypropylene resin, applied in the field of polymer materials, can solve the problems of prolonged processing cycle, increased production cost, increased processing viscosity, etc., and achieves the effects of good dispersion, improved impact resistance and less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

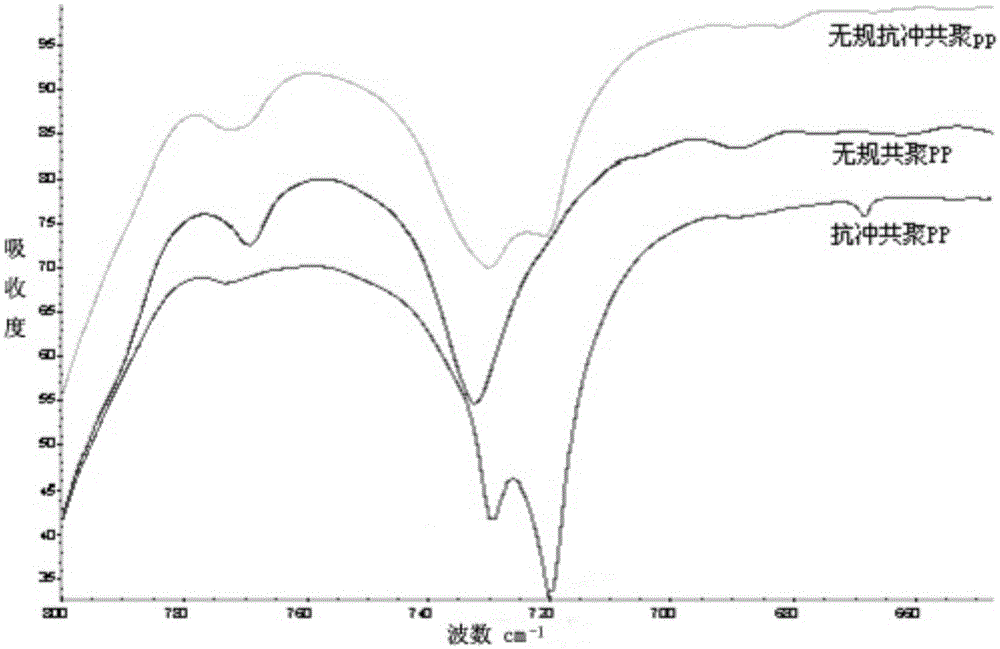

Image

Examples

Embodiment 1-4 and comparative example 1-4

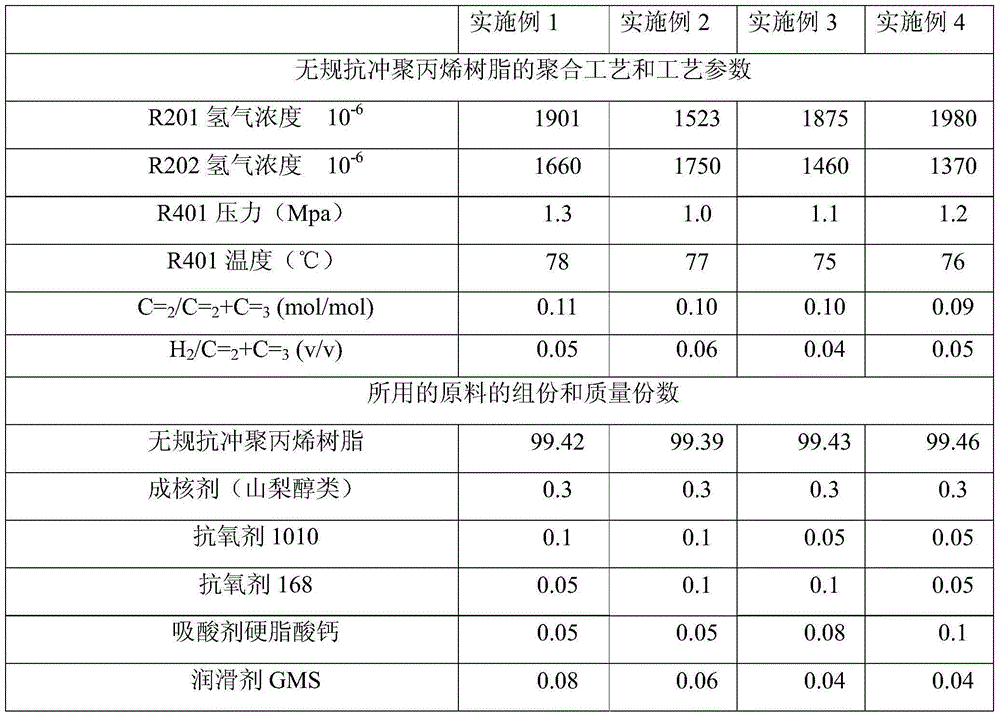

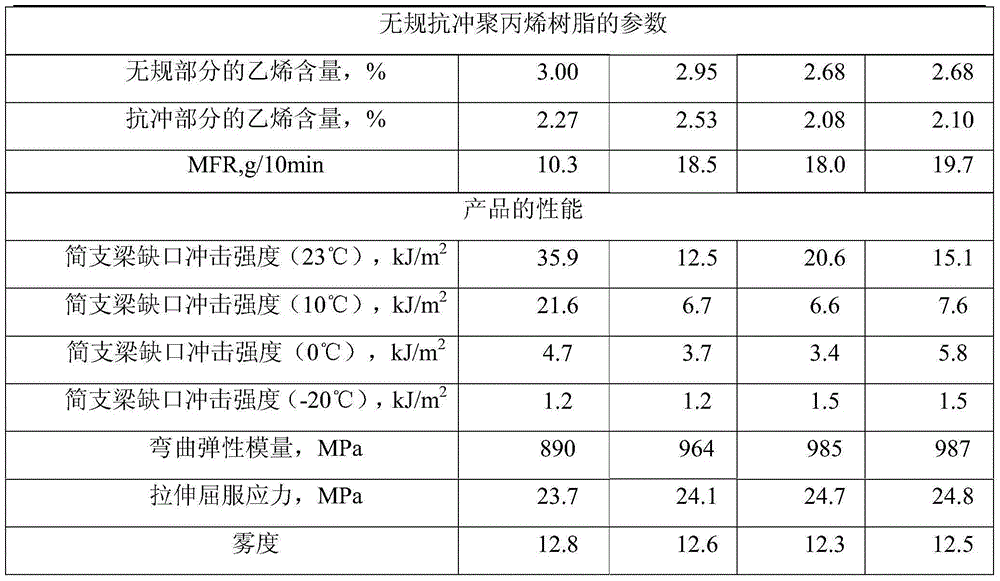

[0034] Embodiment 1-4 prepares a kind of high-impact transparent polypropylene resin, and the raw material used sees the component of the raw material used in Table 1 and the column of mass parts; Polymerization process and The process parameters are shown in the column of polymerization process and process parameters of random impact polypropylene resin in Table 1; the ethylene content of the random part of the random impact polypropylene resin, the ethylene content of the impact part and MFR are shown in Table 1 In the parameter column of random impact polypropylene resin, the performance of the prepared high impact transparent polypropylene resin is shown in the column of product performance in Table 1.

[0035] See Table 2 for the raw material grade performance characterization of the corresponding comparative examples 1-4.

[0036] The standard and the method that the resin product is carried out to performance test in embodiment 1-4 and comparative example 1-4 are as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com