Cylindrical measuring head and measuring method for small gear measurement

A technology of gear measurement and measurement method, applied in the direction of measuring devices, instruments, etc., can solve the problems of poor stiffness of the measuring rod, difficulty in measurement, and inability to measure, so as to improve the measurement efficiency, improve the mechanical precision, and optimize the mechanical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

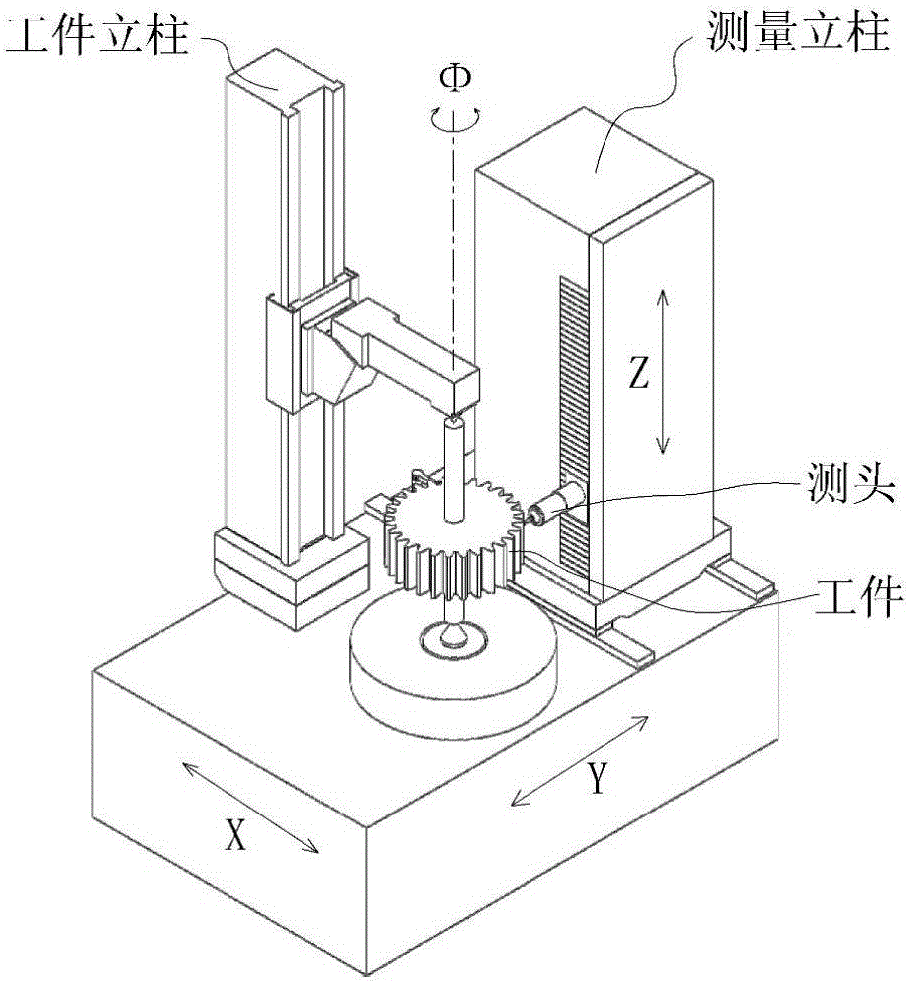

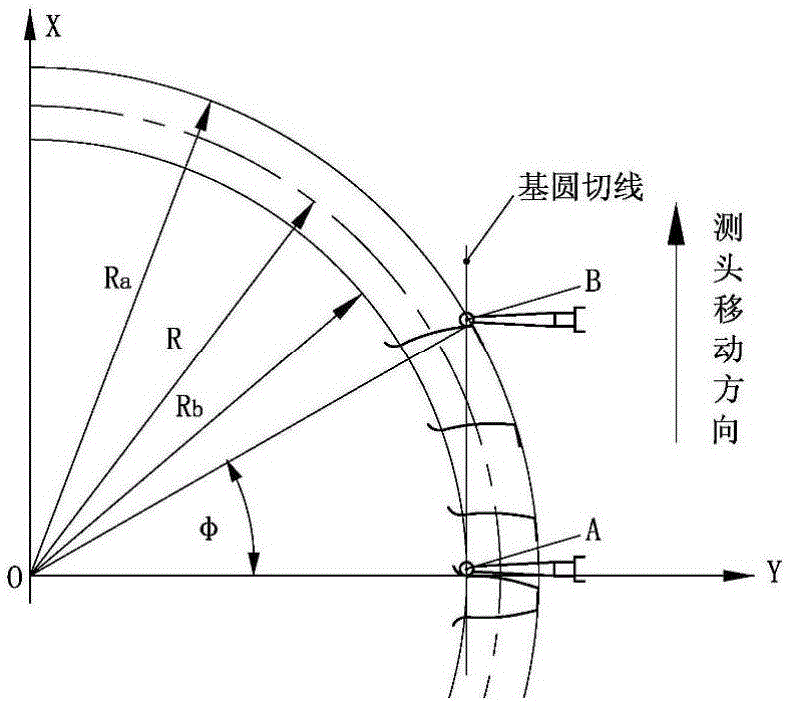

[0028] refer to Figure 7 , the present invention provides a new control method for the involute measurement track, the method is different from the traditional spherical and inverted cone measuring probe used in the existing micro-gear measuring instrument to implement the measurement of the new cylindrical probe.

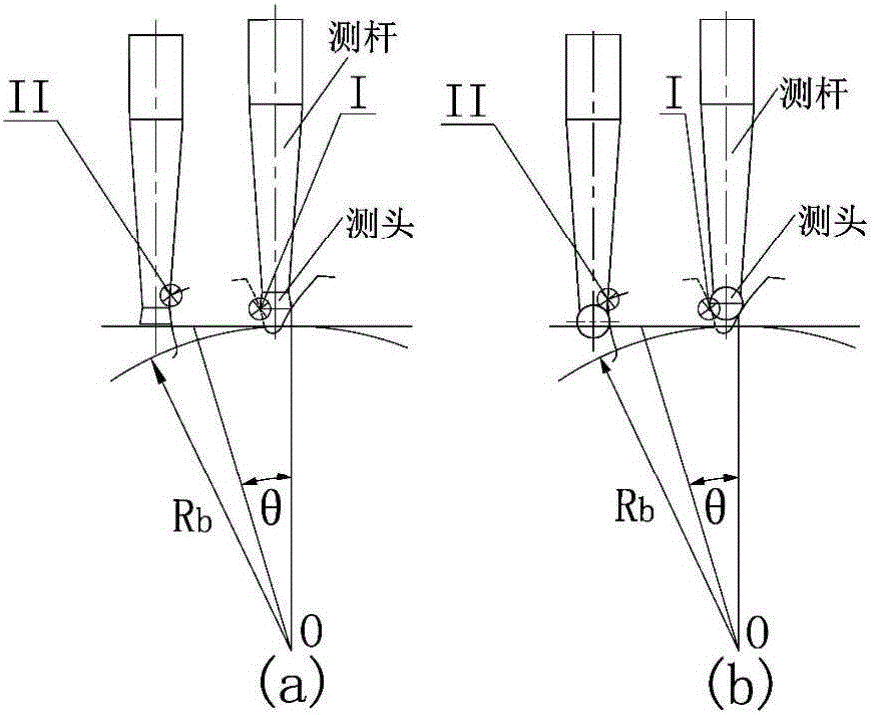

[0029] refer to Figure 6 The measuring head used in the control method of the involute measuring track of the present invention is composed of a measuring rod 1 and a cylindrical measuring needle 2 embedded in the front end of the measuring rod. The needle tip of the measuring needle is ground into a circle perpendicular to the axis of the measuring needle. Shaped end face, the stylus is made of high-hardness tungsten steel cylindrical profile, which can effectively improve the stiffness of the stylus.

[0030] The method for measuring tiny gears by applying the control method of the above-mentioned involute measurement trajectory is composed of the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com